Door plate welding spot identification and welding path planning method

A welding path and path planning technology, applied in welding equipment, auxiliary welding equipment, neural learning methods, etc., can solve problems such as poor adaptability and poor real-time performance, and achieve strong adaptability, improve efficiency, and improve efficiency and accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

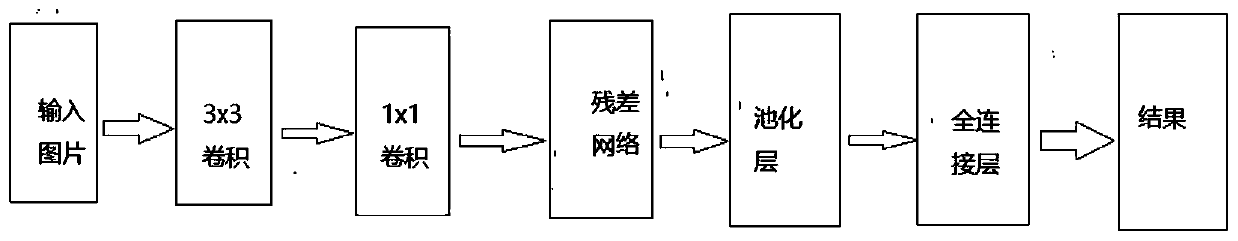

[0038] A door panel welding spot recognition and welding path planning method, comprising the following steps:

[0039] S1. Use a Gaussian filter to filter an image of a car door panel containing solder joints. The filter formula is:

[0040]

[0041] f s (x,y)=f(x,y)*G(x,y,σ)

[0042] Among them, f(x,y), f s (x, y) respectively represent the gray value of each point in the image before and after filtering, G(x, y, σ) is a two-dimensional Gaussian formula, x, y, σ represent the abscissa, ordinate, standard Difference.

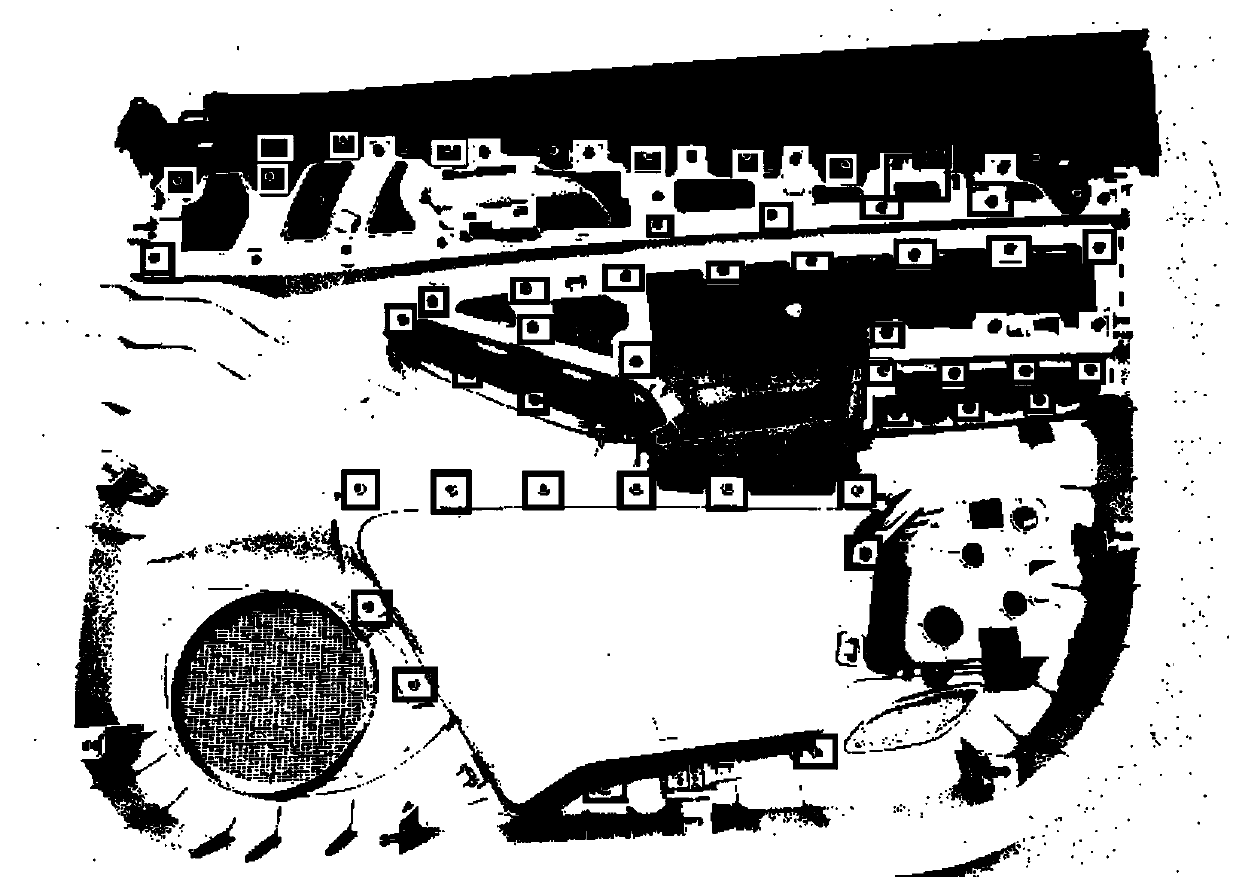

[0043] S2. Perform labeling processing on the image of the automobile door panel to determine the type of solder joints in the image of the automobile door panel, and obtain a labeled data set.

[0044] The distribution of solder joints on the automobile door panel is messy, such as circular, semicircular, oval, etc., so these solder joints need to be labeled. In this embodiment, the labeling tool LabelImg is used to perform the labeling process. The sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com