Die-cutting automatic rubber repairing device

A driving device and automatic technology, which is applied in the direction of grinding/polishing safety devices, grinding machines, metal processing equipment, etc., can solve the problems of affecting devices, taking up a lot of labor time, and loud noise, and achieve the effect of reducing noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

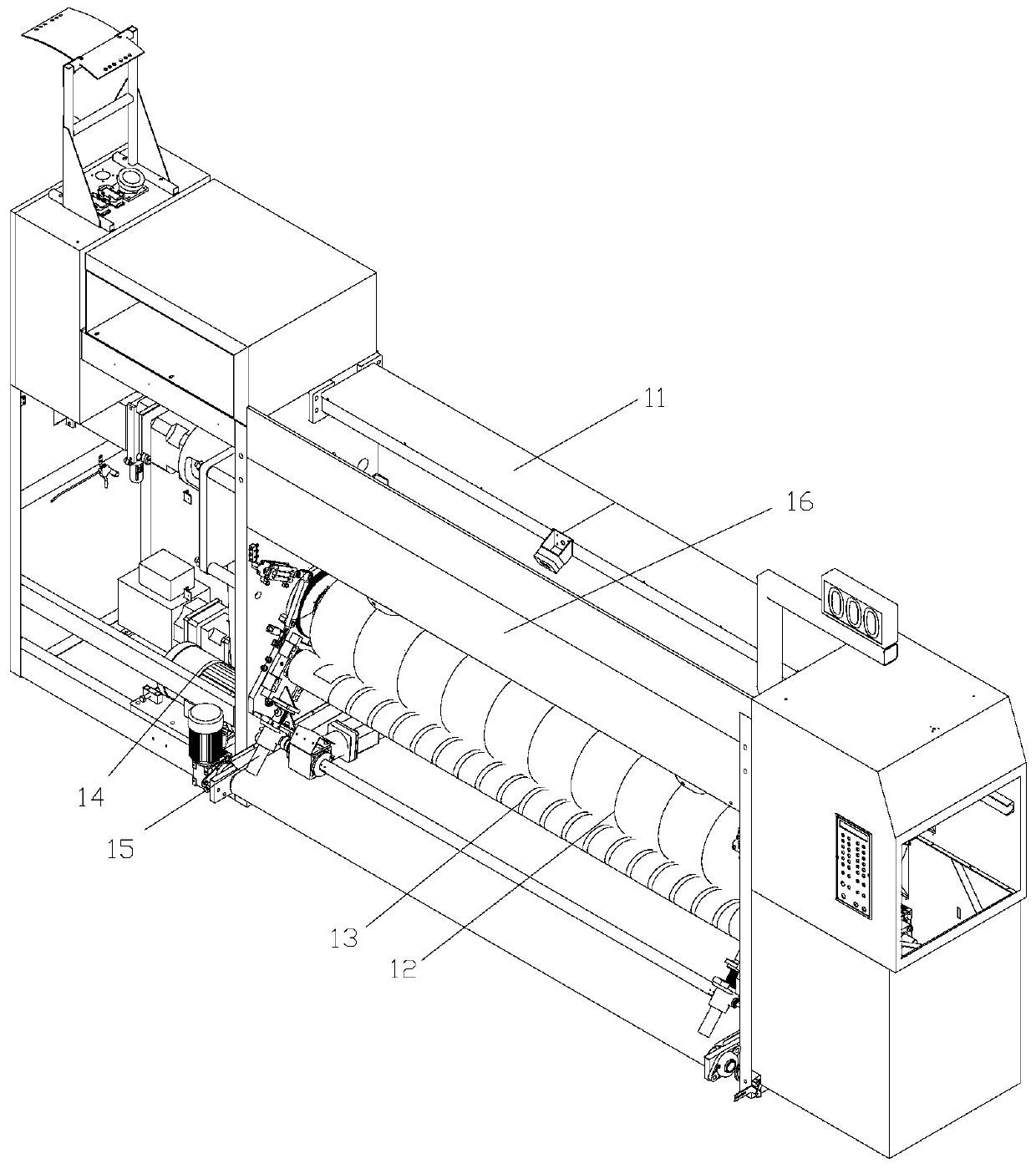

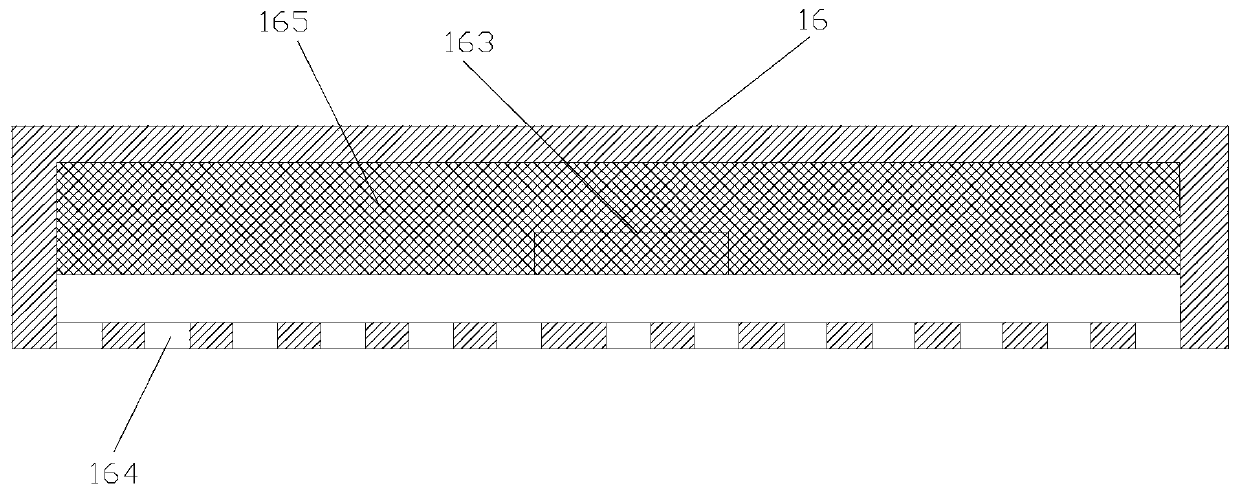

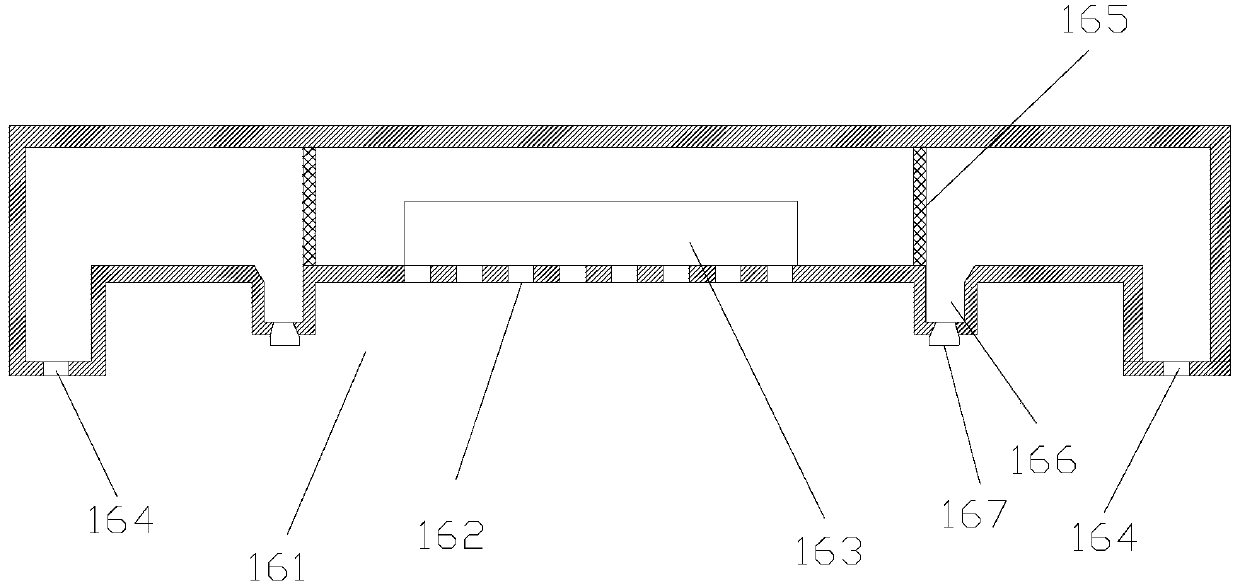

[0025] Embodiment 1, the present invention provides a die-cutting automatic glue repairing device, see Figure 1-Figure 3 , including a housing 11, in which a rubber pad wheel 12, a grinding wheel 13, a driving device and a lift are installed, the rubber pad wheel is connected with the driving device, the grinding wheel is connected with the lift, the Inside the casing, a dust box is also installed above the rubber pad wheel. The dust box includes a box body 16. A groove 161 is arranged at the bottom of the box body. A first hole 162 communicated inside the body, a plurality of the first holes form air outlet holes, the air outlet holes are facing the grinding wheel, and a fan 163 is installed in the box at the positions of the plurality of first holes, The bottom end of the box body is provided with a plurality of second holes 164 on both sides of the groove, which communicate with the inside of the box body. Generally, a plurality of second holes are arranged laterally, and ...

Embodiment 2

[0029] Example 2, on the basis of Example 1, the applicant also made the following design, see Figure 4 , the filter device is a filter screen, and the filter screen is preferably an elastic filter screen, preferably made of non-magnetic material, and the filter screen is laterally fixed with a magnetic elastic sheet 18 in the middle position close to the side of the fan. The magnetic elastic sheet described here It means that the shrapnel contains magnetic material, a spring 19 is longitudinally installed below the magnetic shrapnel, and a magnet block 20 is fixed on the top of the spring, that is, a block made of magnets, and the magnet block and the magnetic shrapnel are spaced apart , In this structure, when the device is in use, the operation of the fan generates vibration, which makes the spring and the magnetic shrapnel vibrate. When the spring moves up and the magnetic shrapnel moves down, the magnet block has an enhanced adsorption force on the magnetic shrapnel, ther...

Embodiment 3

[0031] Example 3, on the basis of Example 1 or Example 2, the applicant also made the following design, see Figure 5 , the top of the dust collecting tank is inclined and fixed with a rubber sheet 168 on the side away from the filter device, and the distance from the top end of the rubber sheet to the filter screen is greater than the position from the bottom end to the filter screen; The bottom of the rubber sheet is provided with a third hole 168-1 horizontally, and the third hole can be set as one or a group (that is, a row), and the side away from the dust collecting tank is provided with a plurality of or Multiple groups (that is, multiple rows) of fourth holes 168-2, one or one group (that is, one row) of fifth holes 168-3 are provided on the side close to the dust collecting tank, and a plurality of the fourth holes are provided Connected with the fifth hole, and a plurality of the fourth holes and the fifth holes are arranged obliquely, and the inclination direction i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com