Self-lifting tower erecting device and method based on semi-rigid composite material tower head crane

A composite material and semi-rigid technology, applied to towers, cranes, building types, etc., can solve the problems of high risk, low efficiency, and high labor dependence, and achieve the effect of low construction risk, reduced safety risk, and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means of the present invention and the technical effects that can be achieved more clearly and more perfectly disclosed, an embodiment is provided hereby, and the following detailed description is given in conjunction with the accompanying drawings:

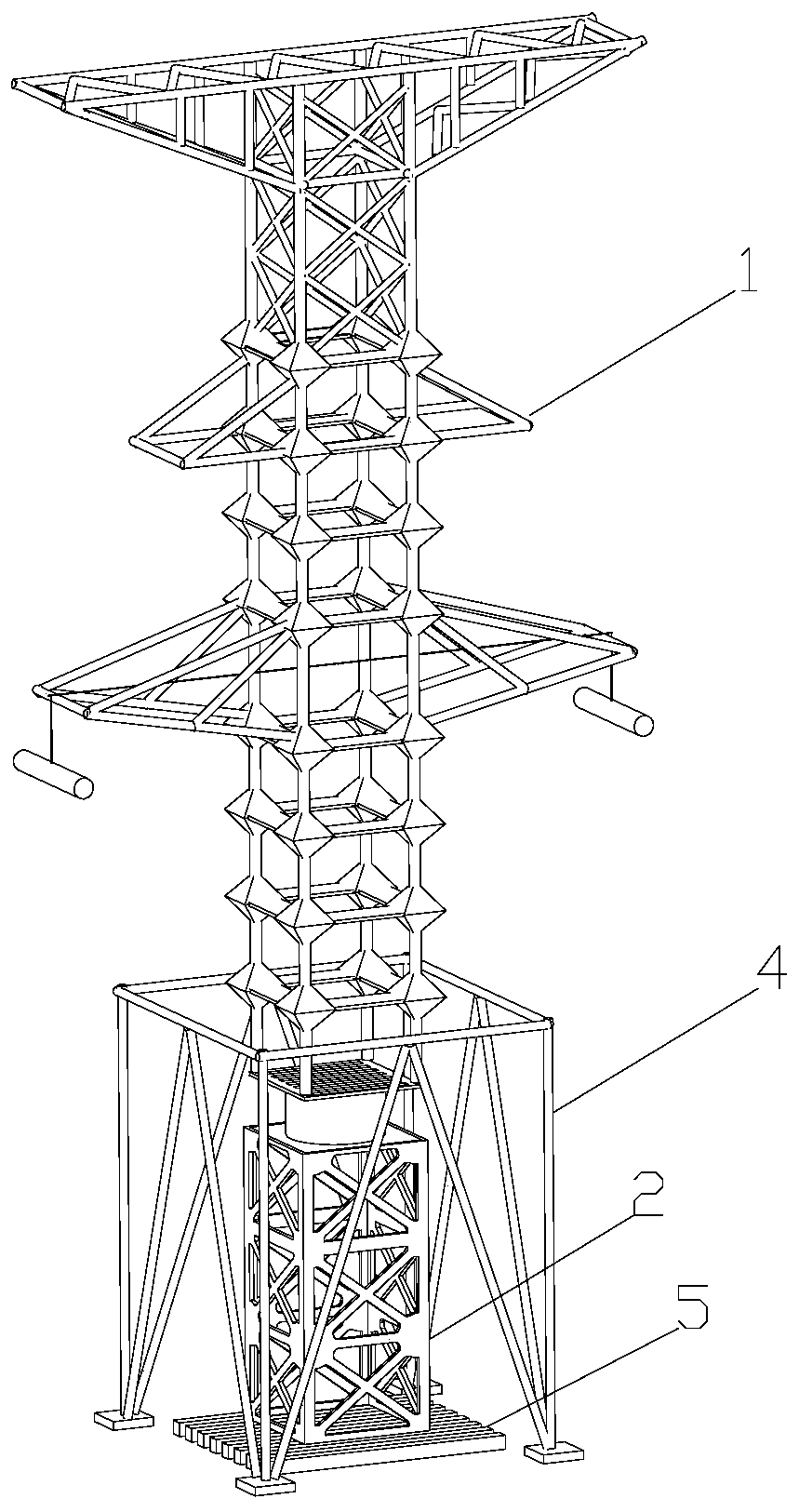

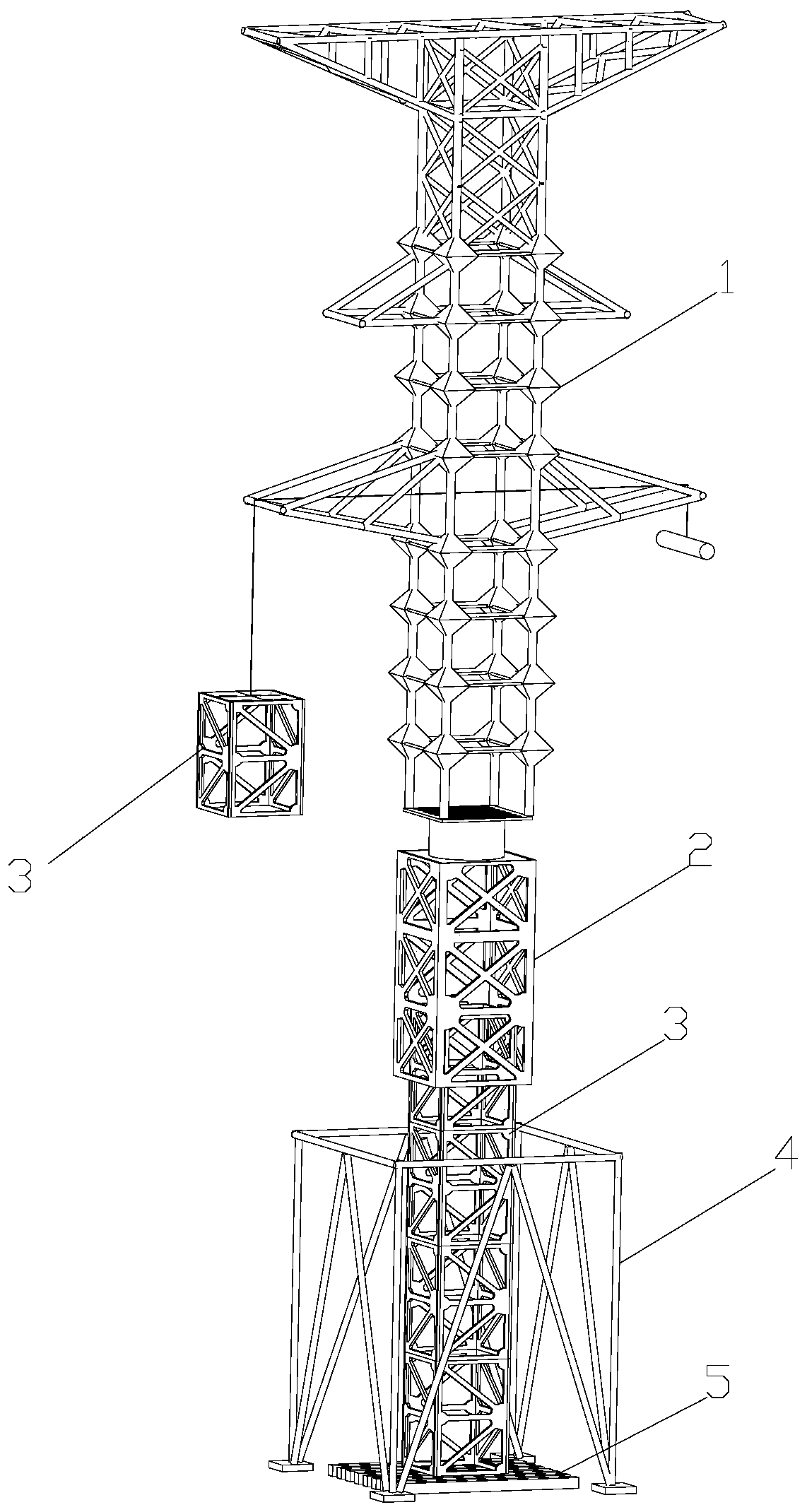

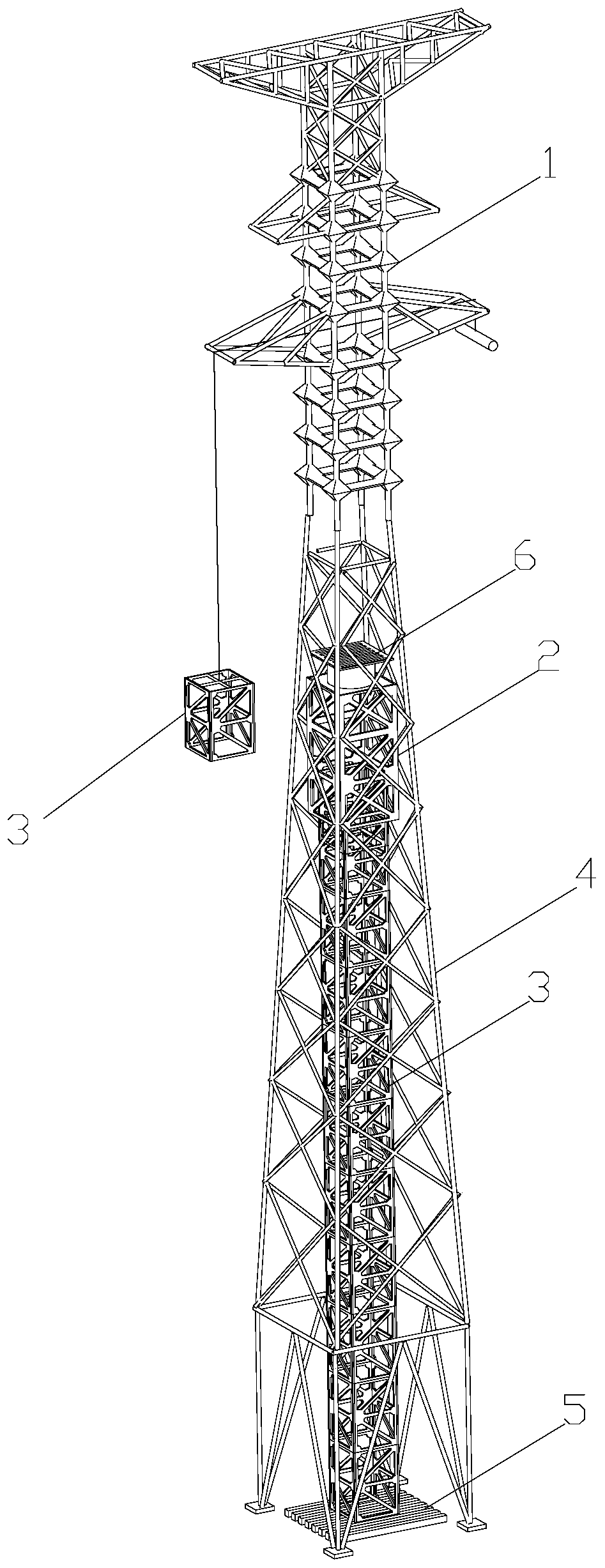

[0024] A self-elevating vertical tower device based on a semi-rigid composite material tower head crane in this embodiment includes a tower crane basic section 2, a plurality of tower crane standard sections 3 that are introduced / extracted from the bottom of the tower crane basic section 2 one by one, and are located on the tower crane basic section. The semi-rigid composite material tower head 1 above the section 2, the tower head 1 crane installed on the tower head 1, and the hydraulic lifting system for lifting or lowering the basic section 2 of the tower crane; the semi-rigid composite material tower head 1 includes The cross arm acts as a double horizontal jib.

[0025] In this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com