Well drilling method using combination system of screw and rotary guide tool

A rotary steering, combined system technology, applied in directional drilling, rotary drilling, rotary drilling rigs, etc., can solve problems such as insufficient wellbore cleaning and ROP limitation, and achieve the improvement of top drive speed, prolong life, reduce high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0023] In the existing technology, when using the combined system of screw and rotary steerable tool to drill wells, the lower top drive speed (40rpm-60rpm) has been used. People in the industry believe that when the screw speed is higher, it is easy to cause damage or even twisting of the screw, but this cognition is Cognitive misunderstandings caused by the limitation of the rotational speed of the bent screw.

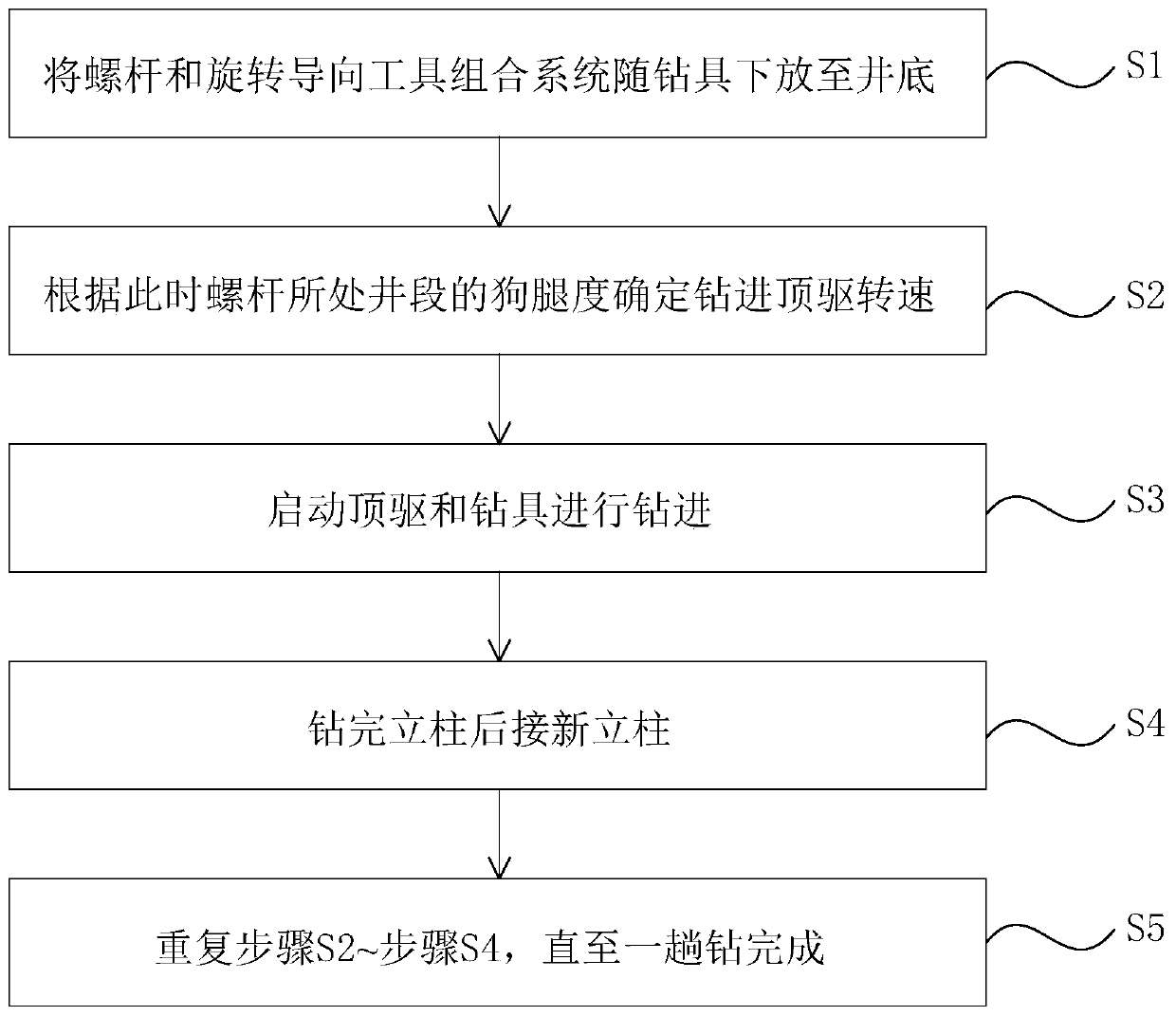

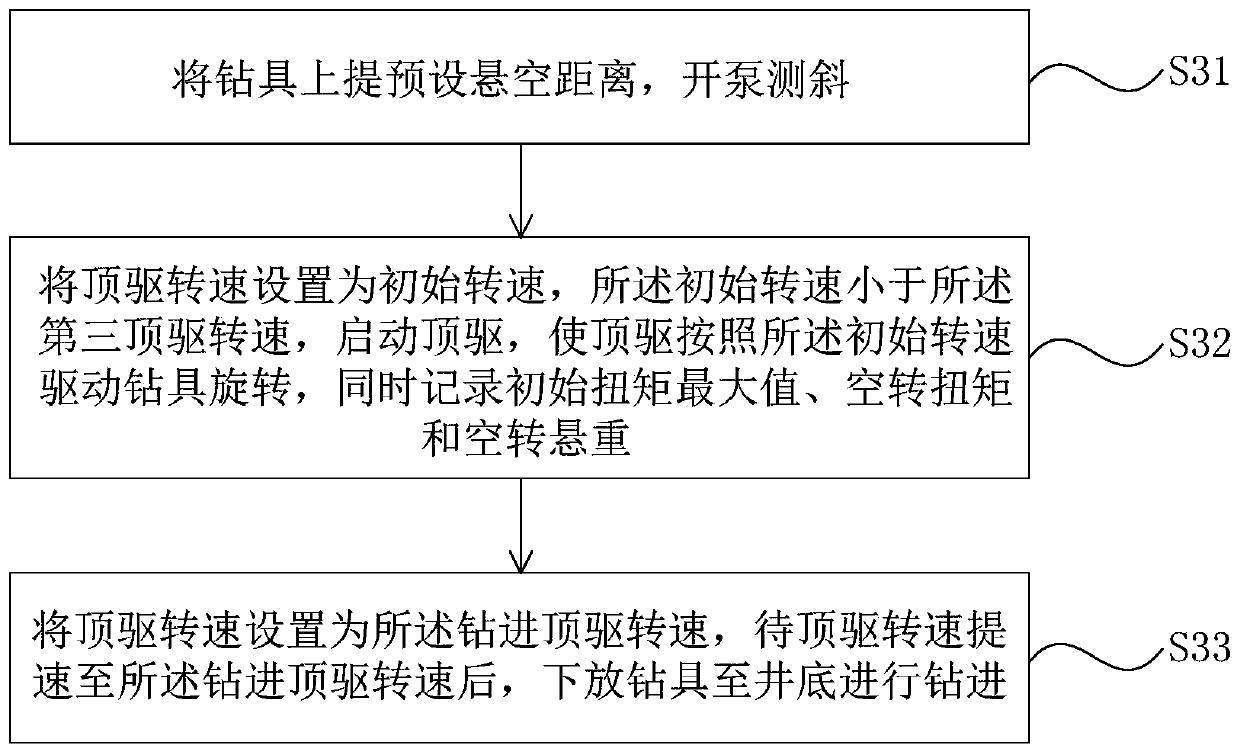

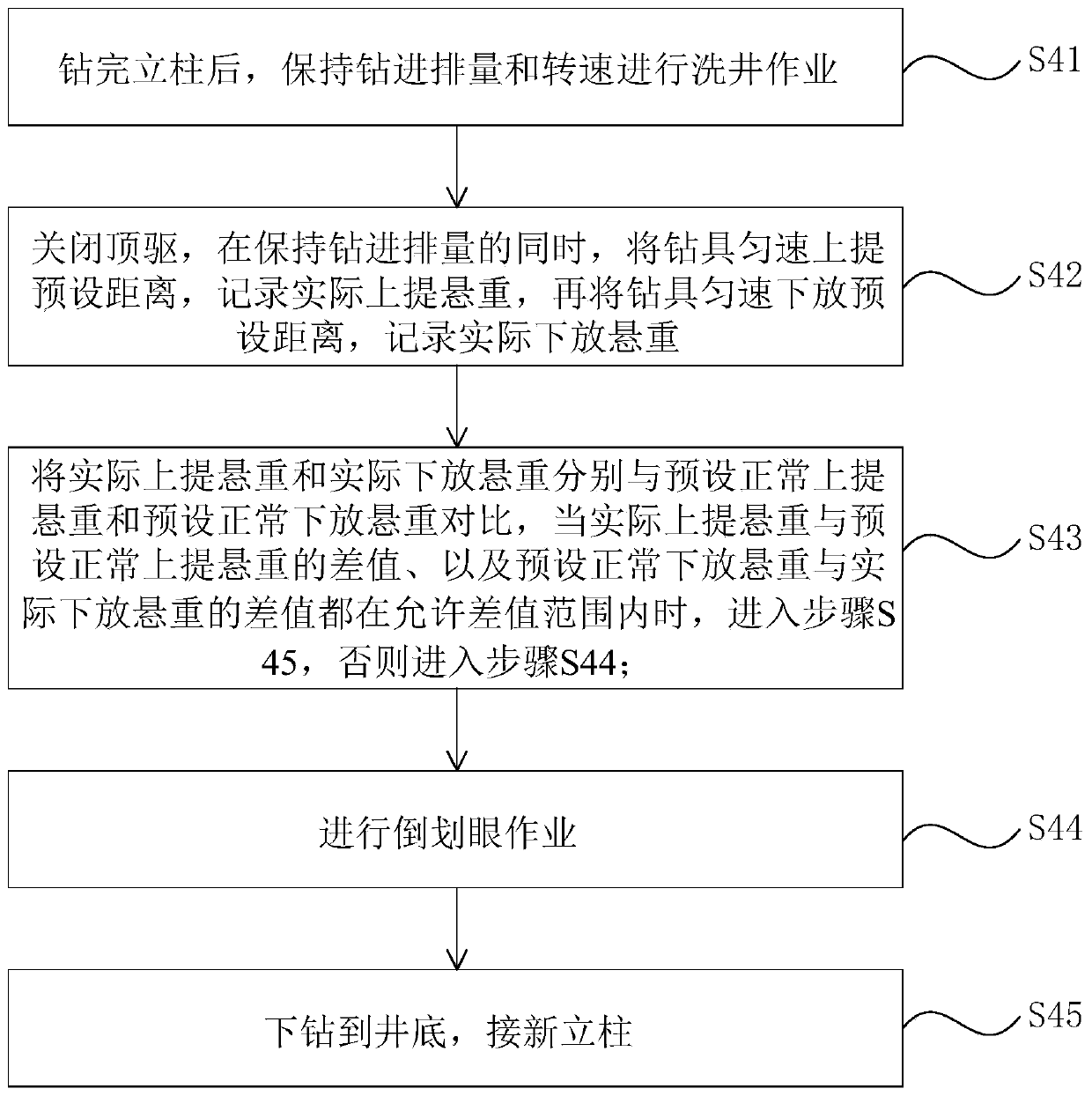

[0024] In order to overcome the cognitive bias of the prior art, the present invention provides a drilling method using a screw and rotary steerable tool combination system, which includes:

[0025] According to the dogleg degree of the wellbore, the wellbore is divided into low dogleg well section, medium dogleg well s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com