Calibration method for ensuring consistency of spectrum modules

A calibration method and consistent technology, applied in the field of radiation detection applications, can solve the problems of narrow application range, impracticability, and low calibration accuracy of spectral resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions in the embodiments of the present invention will be described clearly and in detail below with reference to the drawings in the embodiments of the present invention. The described embodiments are only some of the embodiments of the invention.

[0022] The technical scheme that the present invention solves the problems of the technologies described above is:

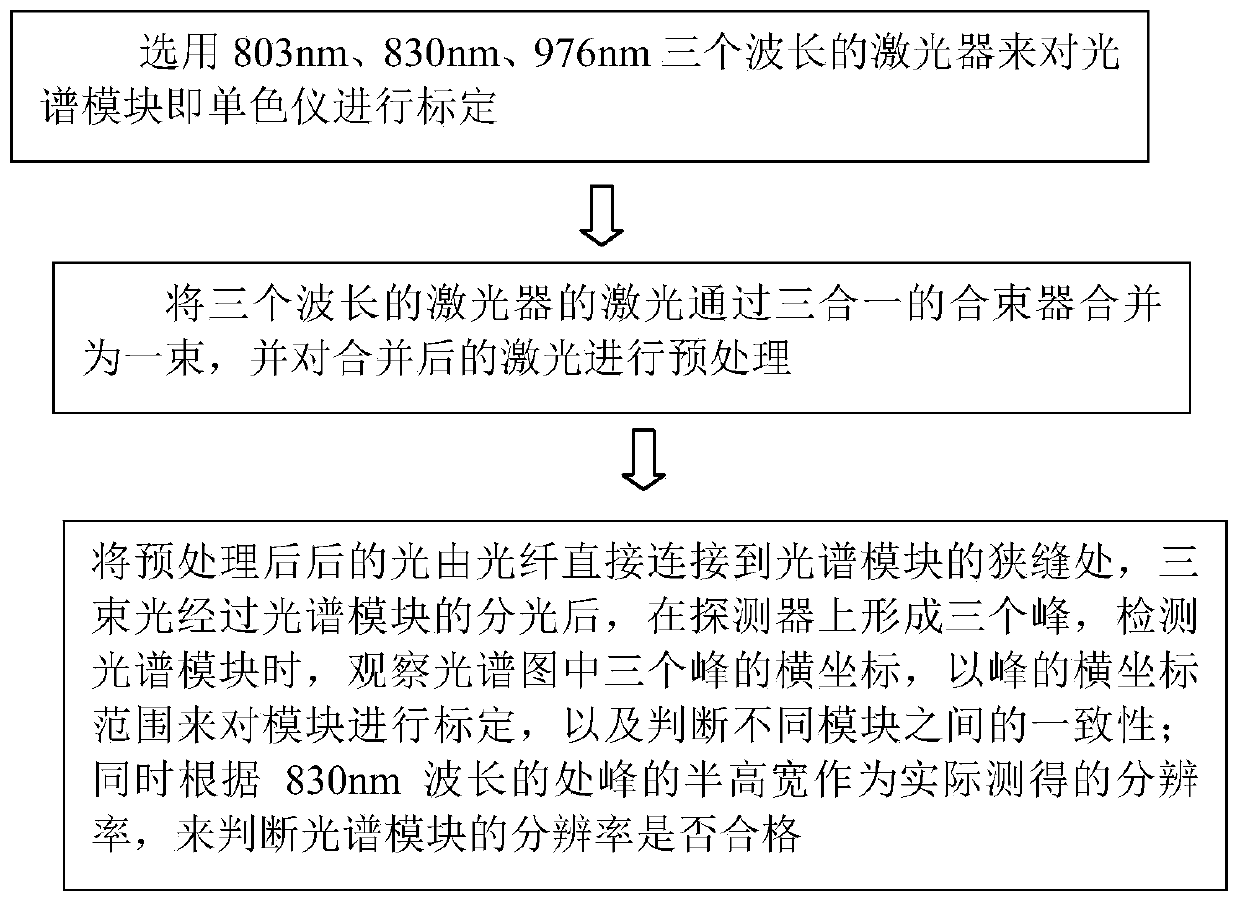

[0023] like figure 1 As shown, a calibration method to ensure the consistency of the spectral module includes the following steps:

[0024] Step 1. Select lasers with three wavelengths of 803nm, 830nm, and 976nm to calibrate the spectral module, that is, the monochromator;

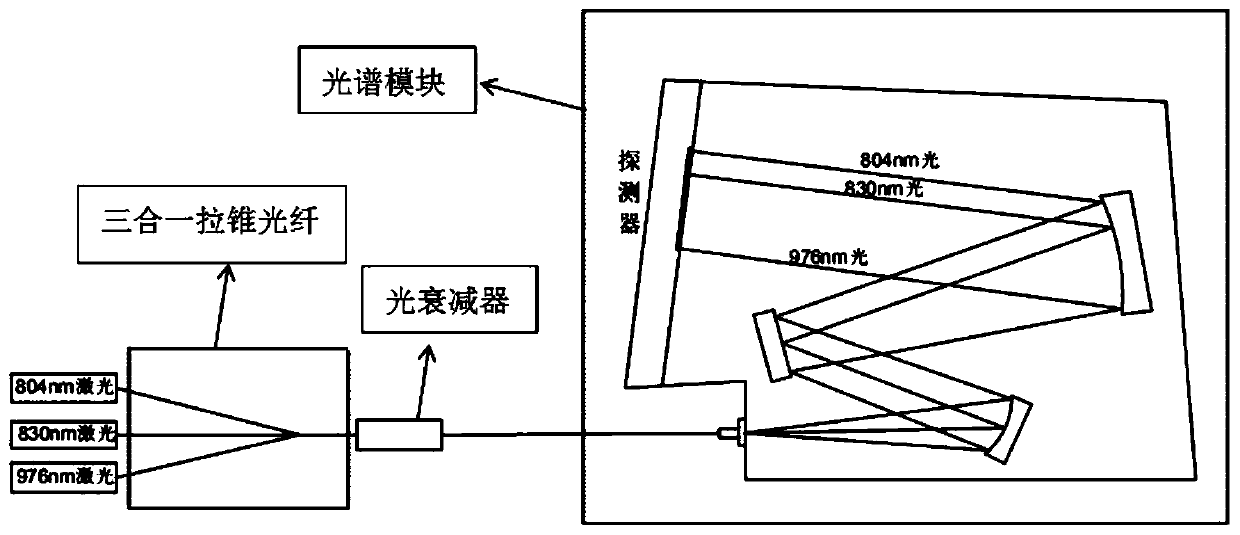

[0025] Step 2. Combine the lasers of the lasers with three wavelengths of 803nm, 830nm and 976nm into one beam through a three-in-one beam combiner, and pre-process the combined lasers;

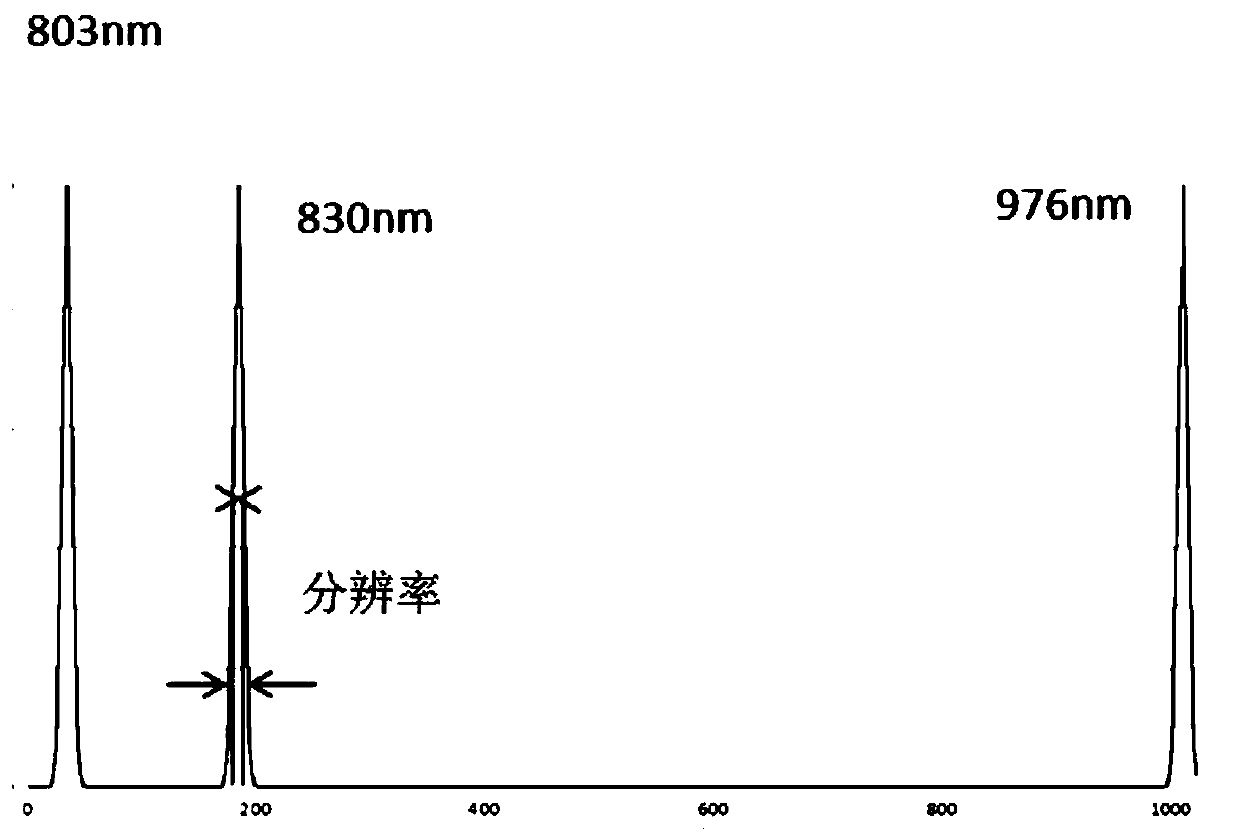

[0026] Step 3. When working, connect the preprocessed light directly to the slit of the spectrum module through the optical fiber. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com