Engine test bench

A technology of engine and platform, which is applied in the direction of engine testing, machine/structural component testing, electrical measurement, etc., can solve the problems of low test efficiency, high cost of vehicle platform construction, and heavy troubleshooting workload. Eliminate troubleshooting workflow, reduce troubleshooting workload, and save construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered below.

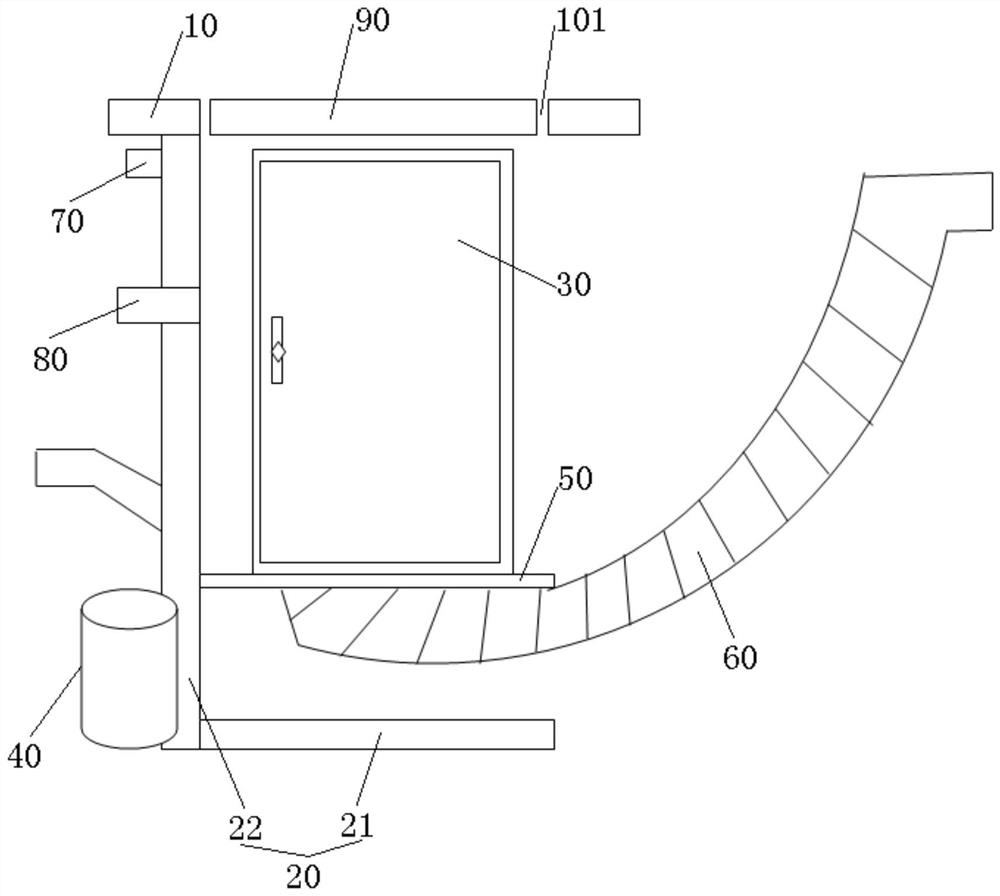

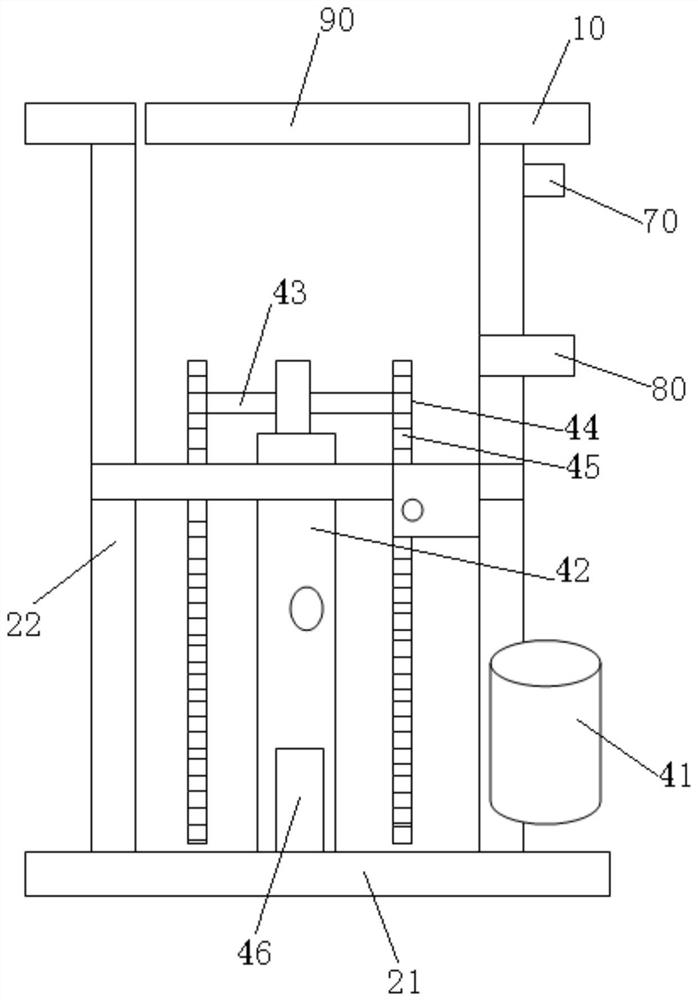

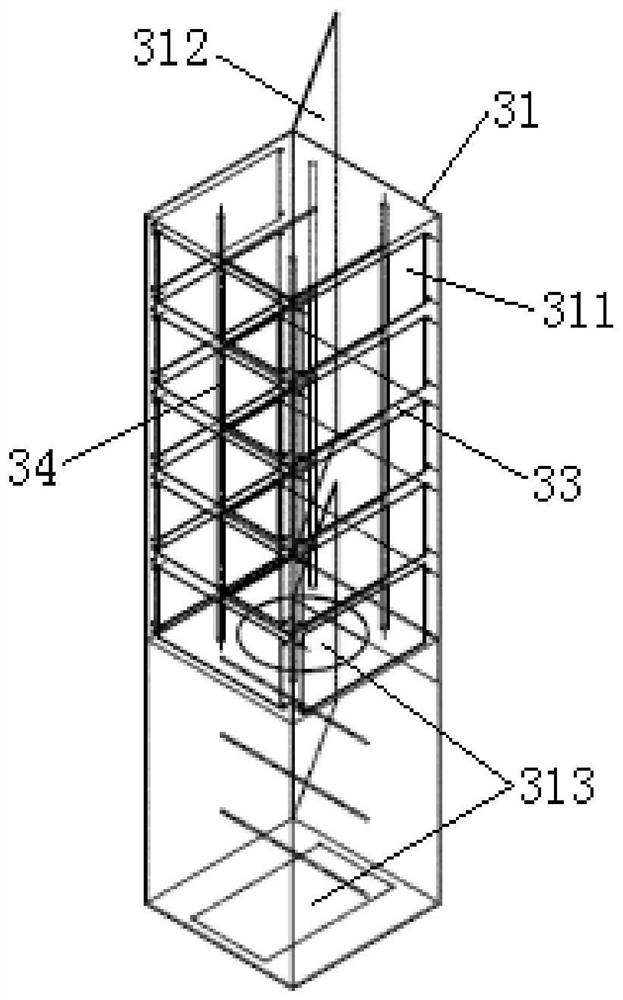

[0028] refer to figure 1 , a preferred embodiment of the present invention provides an engine test bench, comprising: a conventional test room (not shown) located on the upper layer for carrying out conventional engine test tests, and connected below the conventional test room for carrying out engine tests A special test room (not shown) for the electromagnetic compatibility test, and a test switching device arranged in the special test room, the top plate 10 of the special test room is provided with a communication port 101 for connecting with the conventional test room. The test adapter device includes an installation rack assembly 20 vertically arranged in the special test room, an adapter cabinet 30 slidably connected to the installation rack assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com