Self-luminous emergency passage protection strip and preparation method thereof

A technology of emergency passage and protective strip, which is applied to illuminated signs, instruments, display devices, etc., can solve the problem of short self-illumination time, and achieve the effects of long service life, concentrated illumination, and stable use of structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

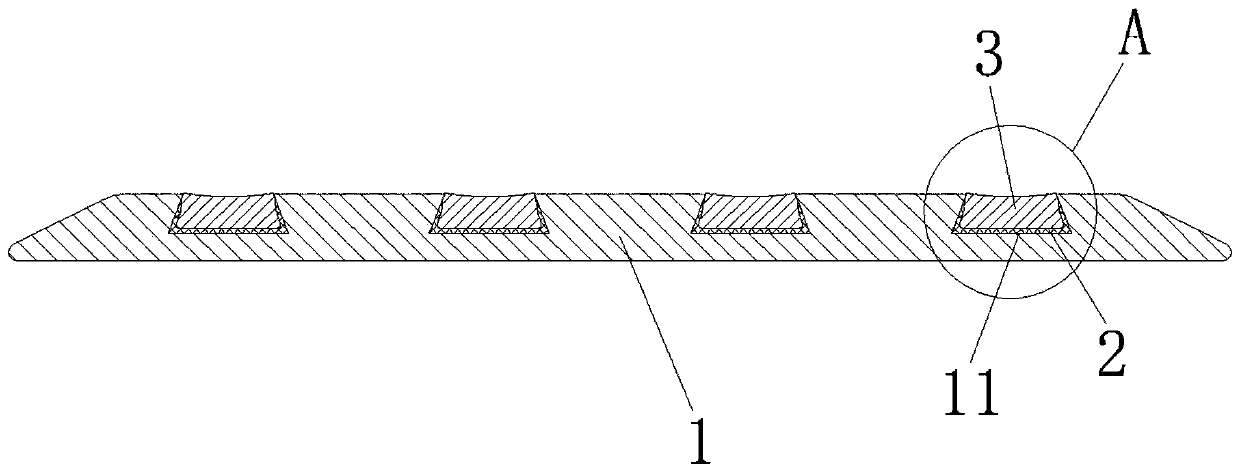

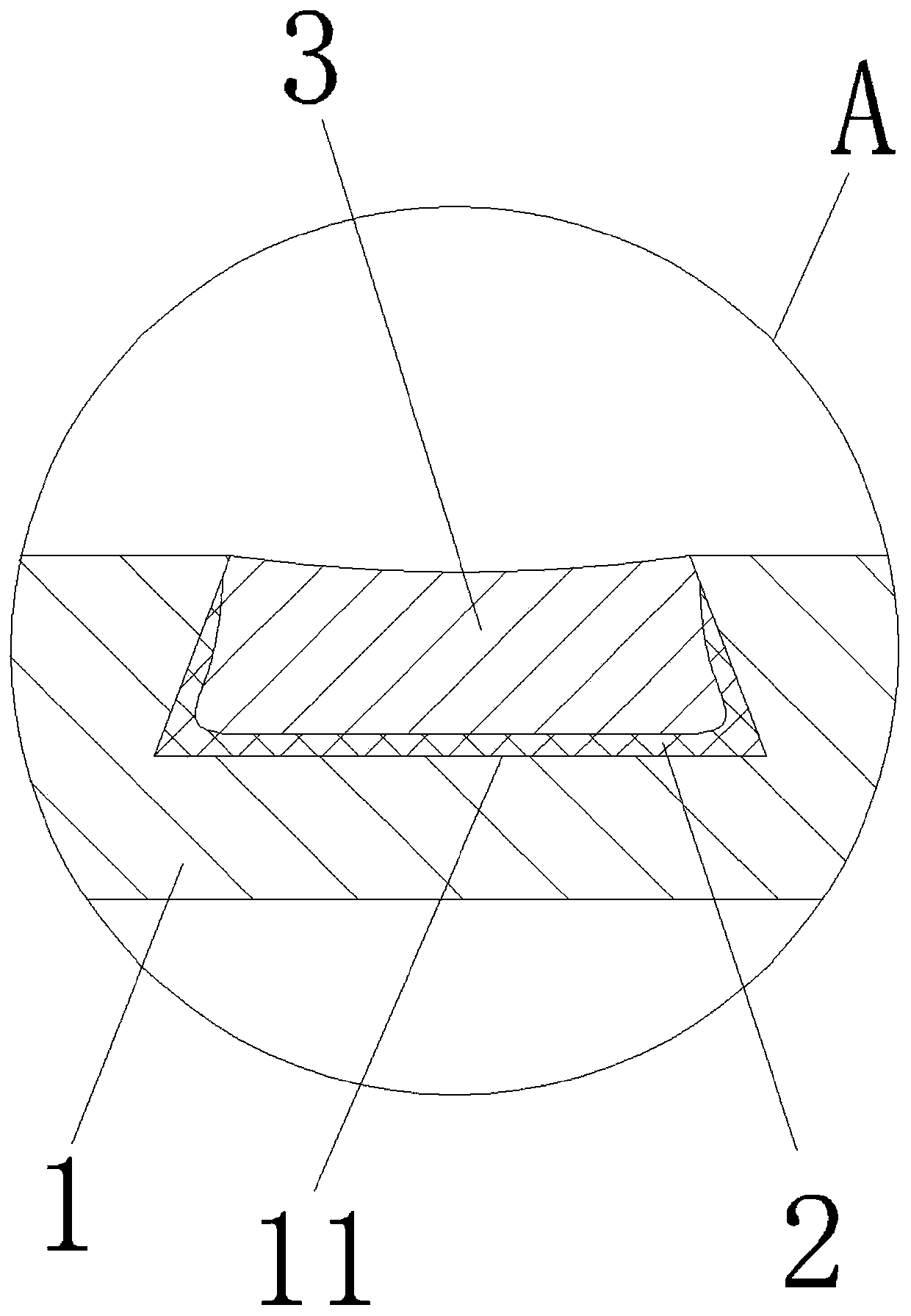

[0037] like Figure 1-6 Shown, a kind of preparation method of self-illuminating emergency exit protective strip, comprises the steps:

[0038] S01, set up a dovetail groove 11 on one side of the visible surface of the protective strip;

[0039] S02, cleaning the dovetail groove 11 of the protective strip and drying it;

[0040] S03, fill the two ends of the dovetail groove 11 in the protective strip with plugging material, the height of the filled plugging material reaches the notch of the dovetail groove 11; after the beeswax solidifies, drop the white resin emulsion on the dovetail groove 11 of the protective strip On the bottom surface, let it stand for 10 minutes until the white resin emulsion is leveled and solidified to form a reflective layer 2;

[0041] S04, pouring mixed ink with fluorescent powder on the leveled reflective layer 2, and standing until the mixed ink with fluorescent powder is solidified to form a light-emitting layer 3;

[0042] S05, cutting the ma...

Embodiment 1

[0051] A method for preparing a self-luminous emergency passage protective strip, the preparation method comprising:

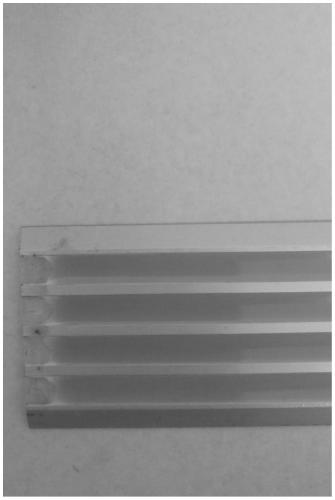

[0052] S01, set a dovetail groove 11 on the visible side of the protective strip; the protective strip is made of aluminum profiles;

[0053] S02, clean the dovetail groove 11 of the protective strip, and use aluminum cleaning agent diluent to clean, and rinse with clean water after cleaning; then dry;

[0054] S03, fill the two ends of the dovetail groove 11 in the protective strip with plugging material, the height of the filled plugging material reaches the notch of the dovetail groove 11; after the beeswax solidifies, drop the white resin emulsion on the dovetail groove 11 of the protective strip On the bottom surface, the dripping amount of the white resin emulsion is controlled by the leveling average thickness of 0.6 mm, and the white resin emulsion is left to stand for 10 minutes to be leveled and solidified to form a reflective layer 2; the plugging m...

Embodiment 2

[0058] A method for preparing a self-luminous emergency passage protective strip, the preparation method comprising:

[0059] S01, set a dovetail groove 11 on the visible side of the protective strip; the protective strip is made of aluminum profiles;

[0060] S02, clean the dovetail groove 11 of the protective strip, and use aluminum cleaning agent diluent to clean, and rinse with clean water after cleaning; then dry;

[0061] S03, fill the two ends of the dovetail groove 11 in the protective strip with plugging material, the height of the filled plugging material reaches the notch of the dovetail groove 11; after the beeswax solidifies, drop the white resin emulsion on the dovetail groove 11 of the protective strip On the bottom surface, the dripping amount of the white resin emulsion is controlled by the leveling average thickness of 1 mm, and the white resin emulsion is left to stand for 10 minutes to be leveled and solidified to form a reflective layer 2; the plugging mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com