Predictive direct power control method

A power control and direct technology, applied in the output power conversion device, the conversion of AC power input to DC power output, electrical components, etc., can solve the problem of large static power difference, poor actual control effect, and harmonic content of grid-side input current. Large and other problems, to achieve the effect of good dynamic and static performance and good steady-state effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, specific embodiments of the present application will be described in detail with reference to the accompanying drawings. According to these detailed descriptions, those skilled in the art can clearly understand the present application and can implement the present application. Without departing from the principles of the present application, the features in different embodiments can be combined to obtain new implementations, or some features in certain embodiments can be replaced to obtain other preferred implementations.

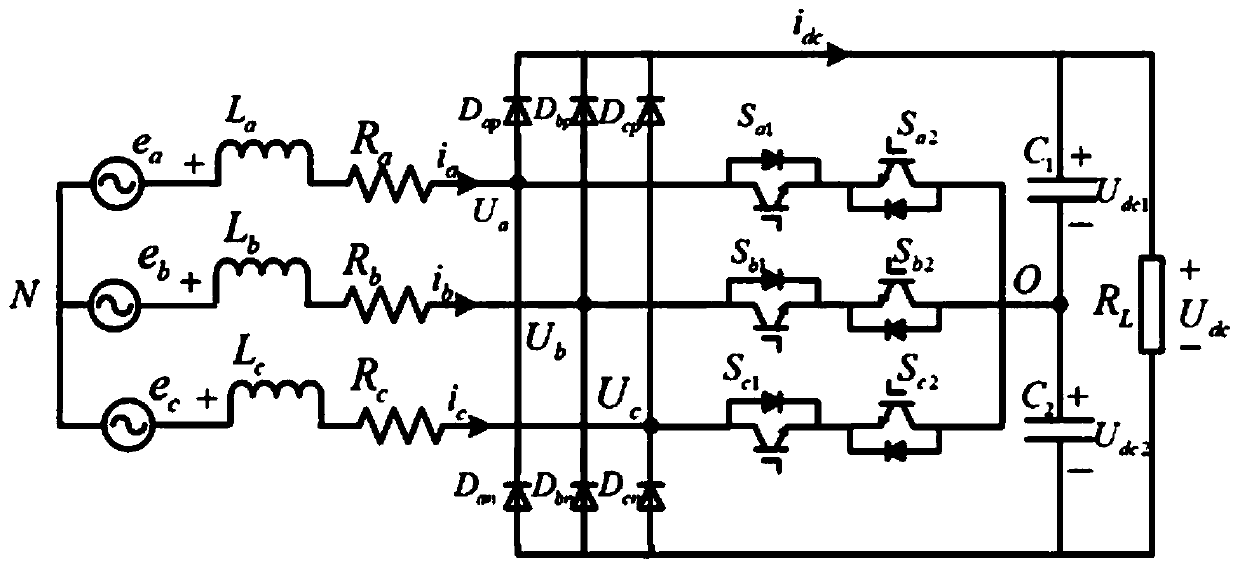

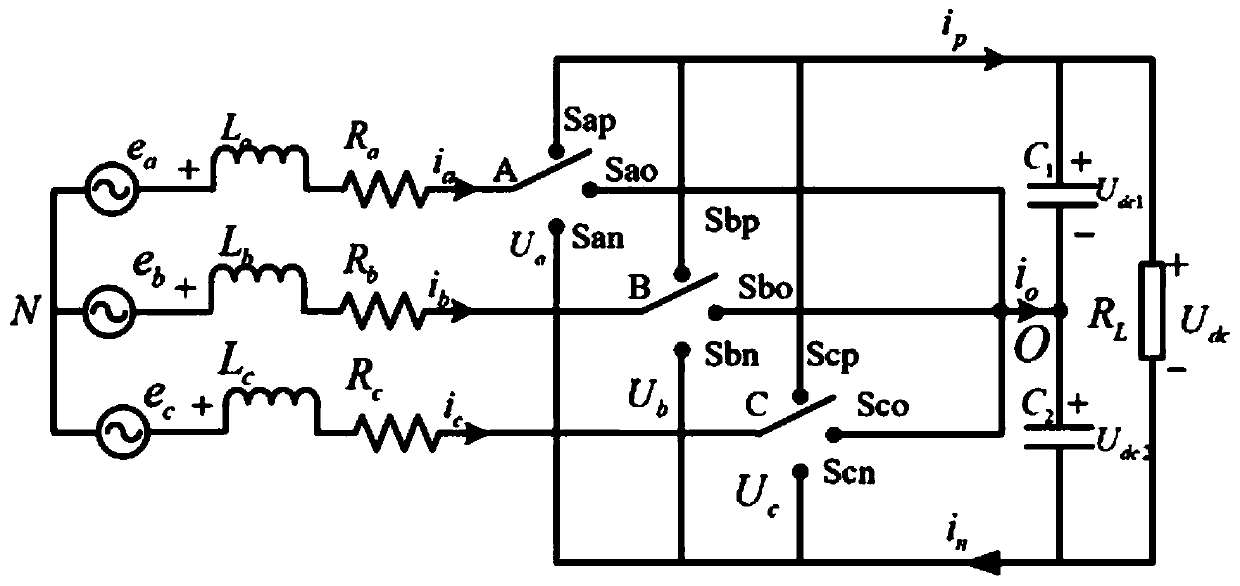

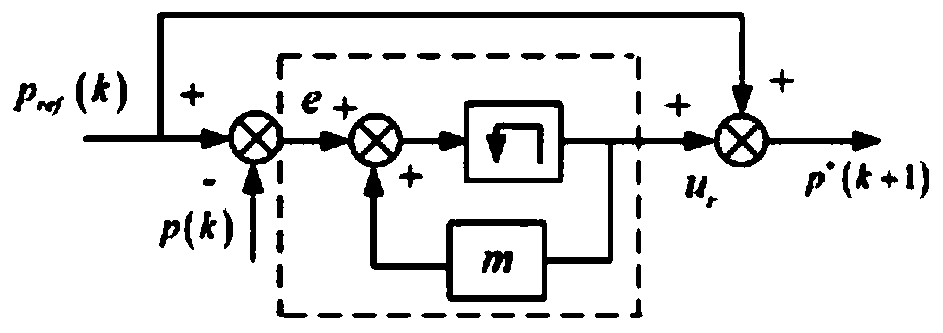

[0037] refer to Figure 1~4 , the present application provides a predictive direct power control method, the method comprising the following steps:

[0038] Step 1): set up the mathematical model of the rectifier in the two-phase stationary coordinate system, obtain the instantaneous active power and the instantaneous reactive power of the rectifier in the two-phase stationary coordinate system;

[0039] Step 2): design the index functi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com