A kind of H-shaped frame welding deformation control device and control method

A welding deformation and control device technology, applied in welding equipment, welding equipment, auxiliary equipment, etc., can solve the problems of base metal collapse, insufficient processing volume, weld crack structure, etc., and achieve the effect of shortening the manufacturing cycle and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

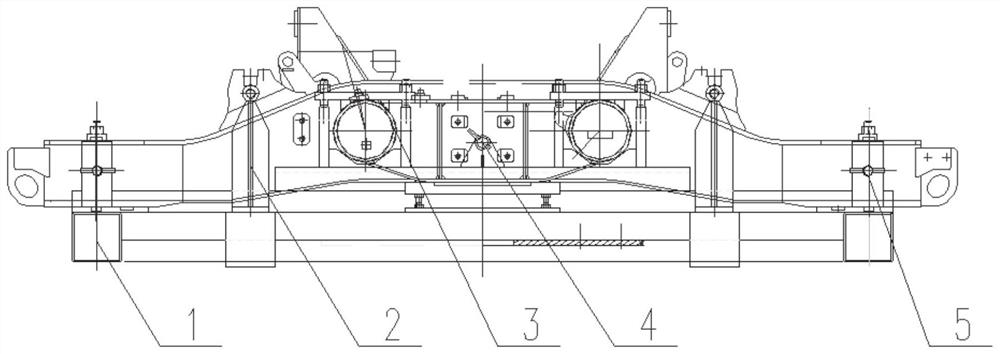

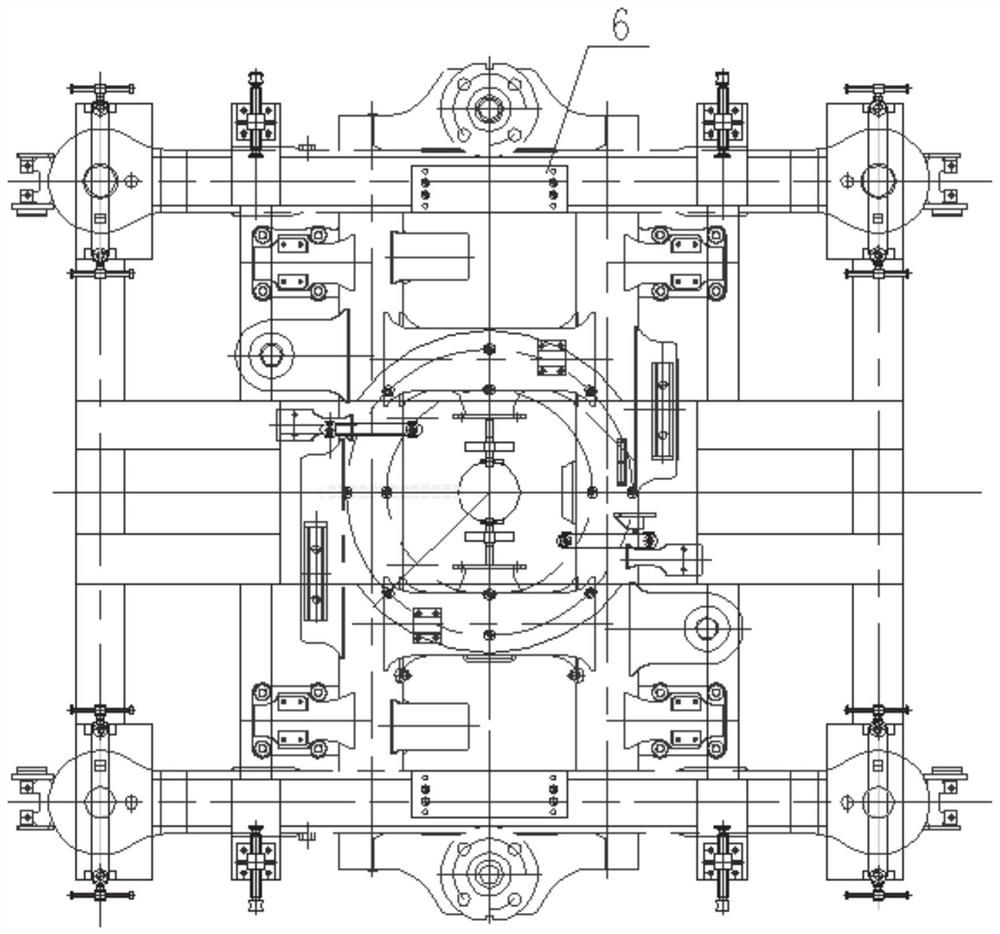

[0047] See attached figure 1 , 2 As shown, this embodiment discloses an H-shaped frame welding deformation control device, which consists of a clamp body 1, a positioning arm fixing device 2, a beam fixing device 3, a beam tightening device 4, a spring tube fixing device 5, and an adjustable support in the middle 6 composition.

[0048] The technical scheme of this implementation example aims at the deformation of the frame welding mainly due to the deformation of the side beam caused by the welding of the ring weld seam of the frame and the weld seam of the outer air spring support beam of the side beam. , to achieve control of welding deformation.

[0049] Attached to this application figure 1 , 2 The H-shaped frame welding deformation control device shown is the optimal implementation example. In an implementation example, the H-shaped frame welding deformation control device can select the clamp body 1, the positioning arm fixing device 2, and the spring tube fixing d...

Embodiment 2

[0069] Based on an H-shaped frame welding deformation control device in the above implementation example, this embodiment discloses a method for controlling the H-shaped frame welding deformation, including:

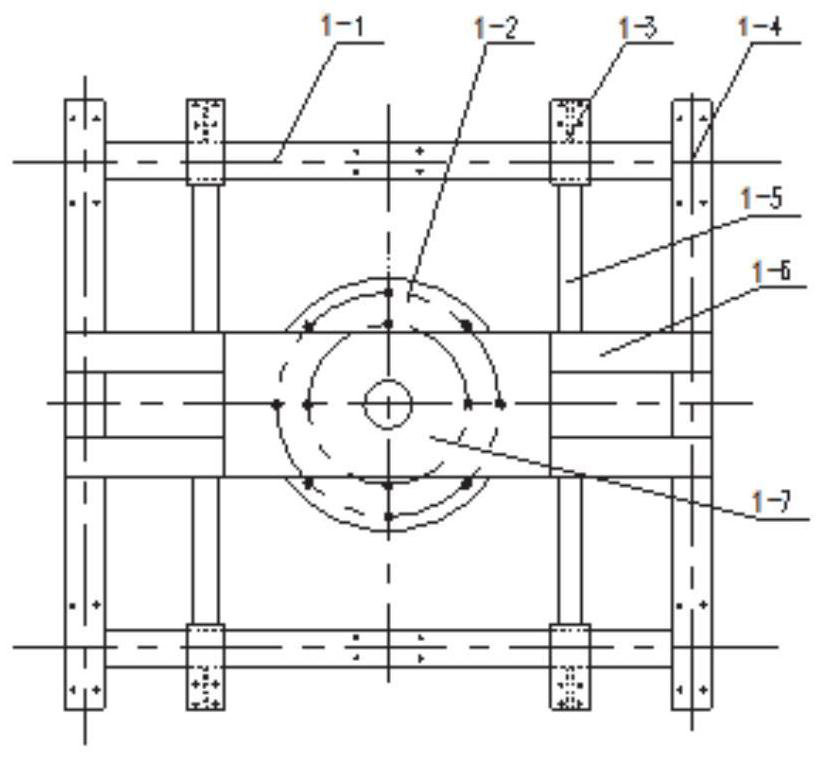

[0070] Clamp the frame to the clamp body, adjust the position of the spring tube, align the center line of the spring tube with the center line of the scale, fix and clamp the frame, and adjust the spring tube fixing device 5-4 and the second tensioner after the inner ring weld of the frame is welded and filled. , Prefabricated 2mm anti-deformation to the inside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com