Logistics turnover device and machining method

A logistics and support device technology, applied in the direction of transporting objects, goods transport vehicles, transportation and packaging, etc., can solve the problems of road bumps, affecting the use effect, damage, etc., to reduce injuries, improve production efficiency, and reduce scrap rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

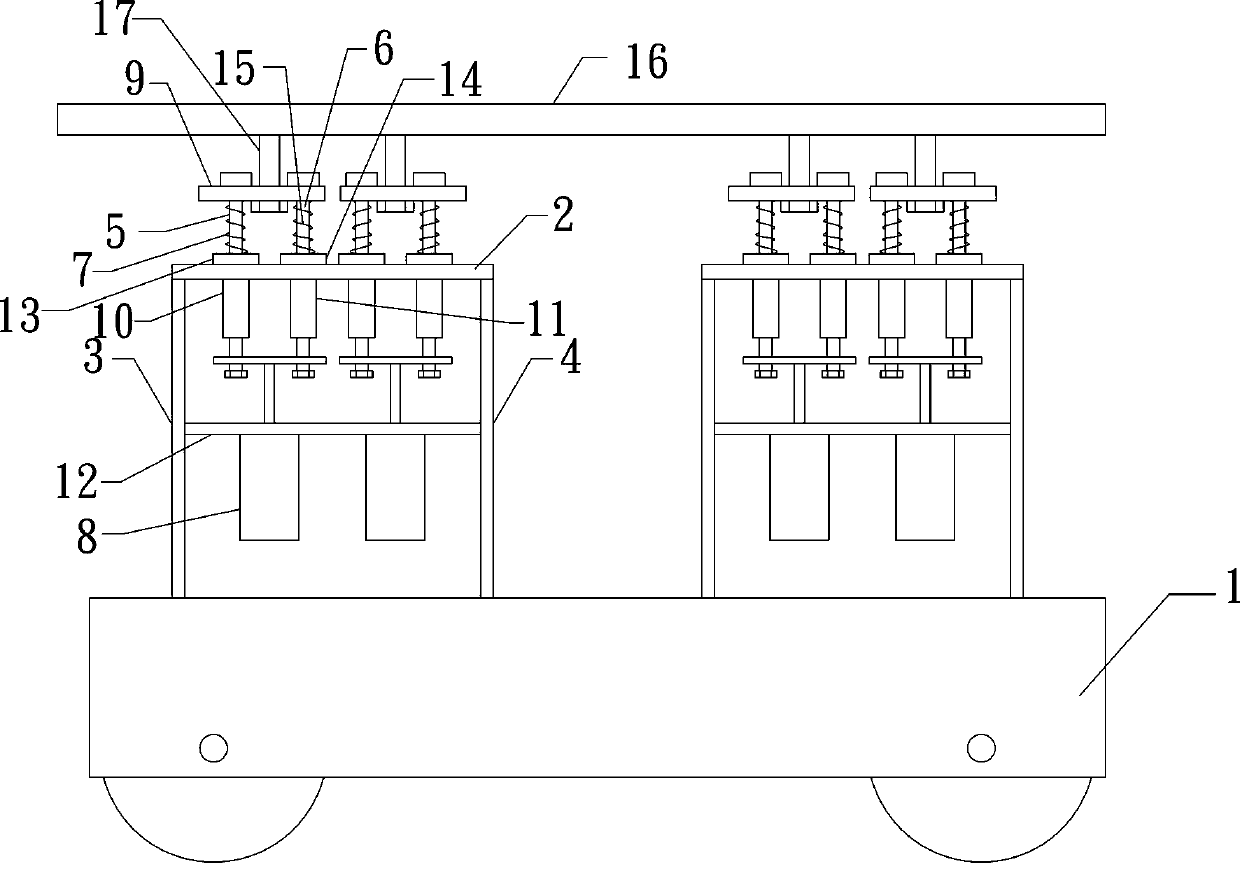

[0033] Such as figure 1 with image 3 As shown, the logistics turnover device includes an AGV automatic guided transport vehicle 1, the shape of the AGV automatic guided transport vehicle 1 is a cuboid, and the AGV automatic guided transport vehicle 1 includes a frame and a car body located above the frame, Moreover, a traveling wheel device is provided at the bottom of the vehicle frame, and a shock-absorbing lifting support device installed on the upper surface of the vehicle body. There are multiple shock-absorbing lifting support devices with the same structure, and the rectangular arrays are distributed in the upper surface of the vehicle body.

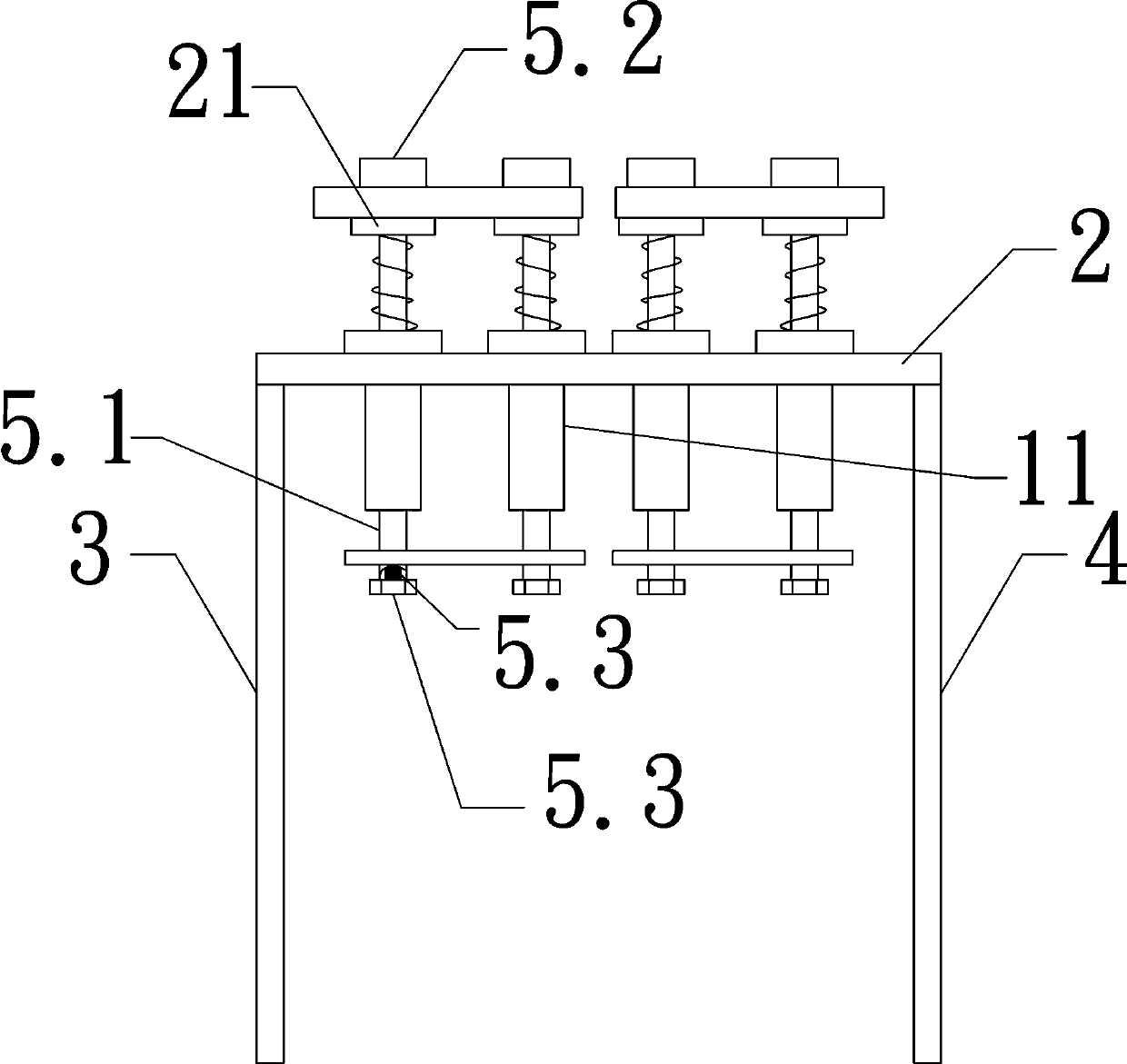

[0034] In this embodiment, the shock-absorbing lifting support device includes a lower mounting plate 2, the lower mounting plate 2 is a strip-shaped thin plate structure, and the two ends of the lower mounting plate 2 are respectively vertically connected with a vertical plate 4 and the vertical plate one 4, the bottom ends of t...

Embodiment 2

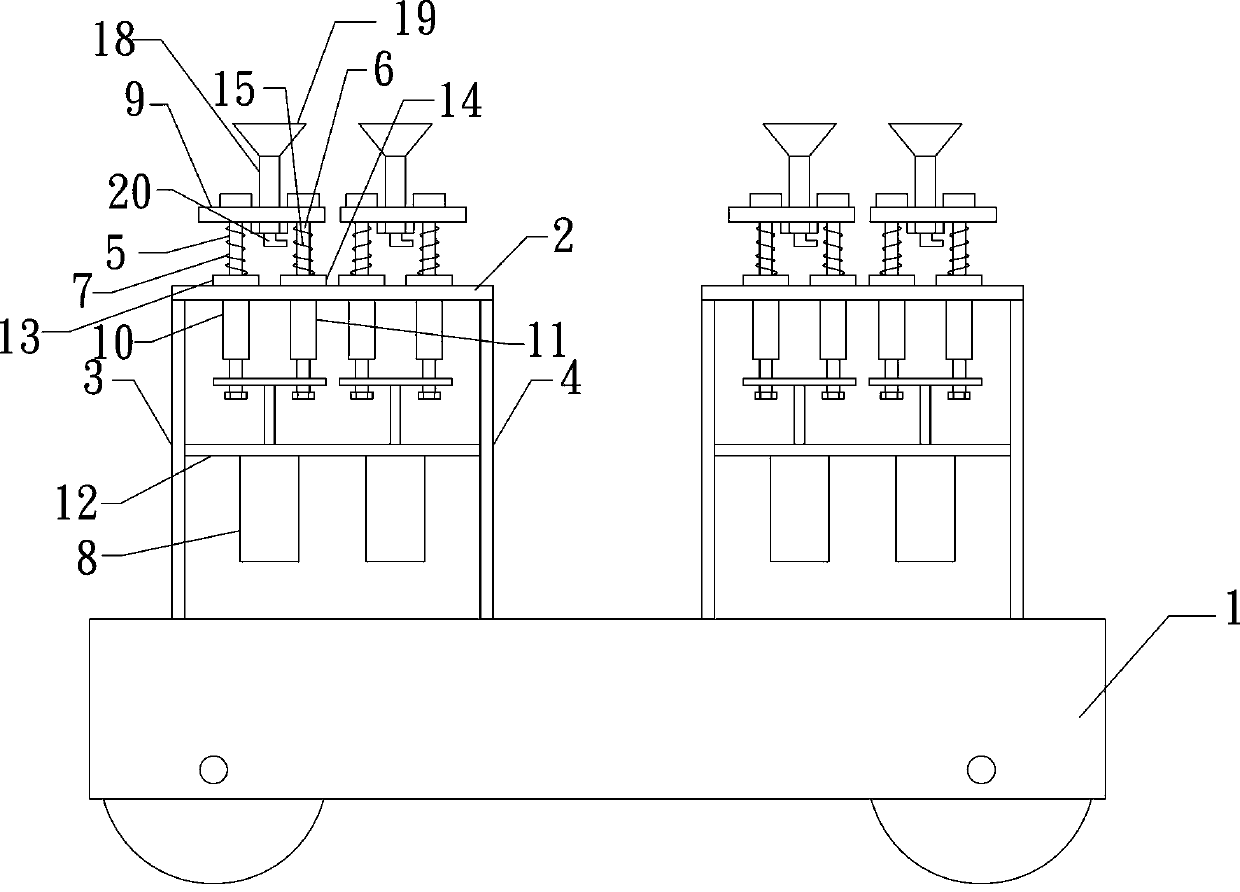

[0038] The difference from Embodiment 1 is that the support body includes a communication pipe 18 installed in the middle of the upper mounting plate 9, a vacuum suction cup 19 is installed on the top of the communication pipe 18, and an air source is installed at the bottom end of the communication pipe 18. pipe joint 20.

[0039] Implementation 1 and Implementation 2 have different fixing methods for the items. In Implementation 1, the upper pallet 16 is used to hold up the items to be transferred. In Embodiment 2, the air source pipe joint 20 is used to connect the negative pressure device, and the vacuum suction cup 19 is adsorbed on the surface of the items to realize Fixation of items.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com