Soft package battery tray replacing and loading method, soft package battery manipulator and storage medium

A technology of soft-pack batteries and manipulators, which is applied to battery assembly machines, manipulators, program-controlled manipulators, etc. It can solve the problems of battery surface scratches, high battery damage rate, pinch damage, etc., so as to improve product yield and reduce battery damage rate, the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The changing of the soft pack battery 30, the tray loading operation refers to that after the previous process is completed, the soft pack battery 30 is taken out of the soft pack battery 30 from the tray of the previous process, and transferred to the tray position of the next process to place the soft pack battery 30 The battery pack 30 is put into the tray of the next process.

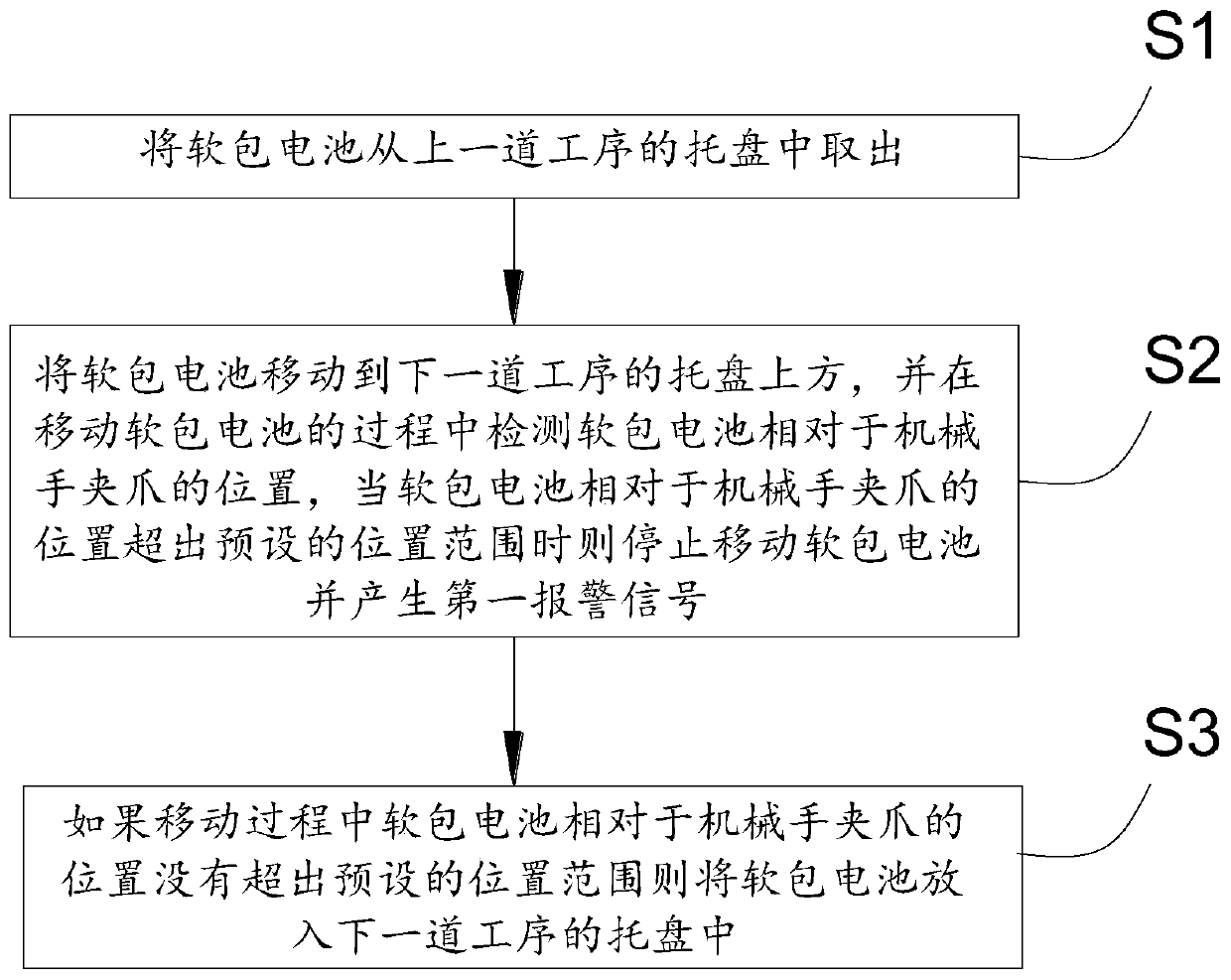

[0036] Such as figure 1 As shown, this embodiment provides a method for changing and loading soft-pack batteries, including the following steps:

[0037] S1. Take out the pouch battery 30 from the tray in the previous process;

[0038] S2. Move the pouch battery 30 to the top of the pallet in the next process, and detect the position of the pouch battery 30 relative to the gripper 11 of the manipulator during the process of moving the pouch battery 30. When the pouch battery 30 is relative to the gripper of the manipulator When the position of 11 exceeds the preset position range, stop movi...

Embodiment 2

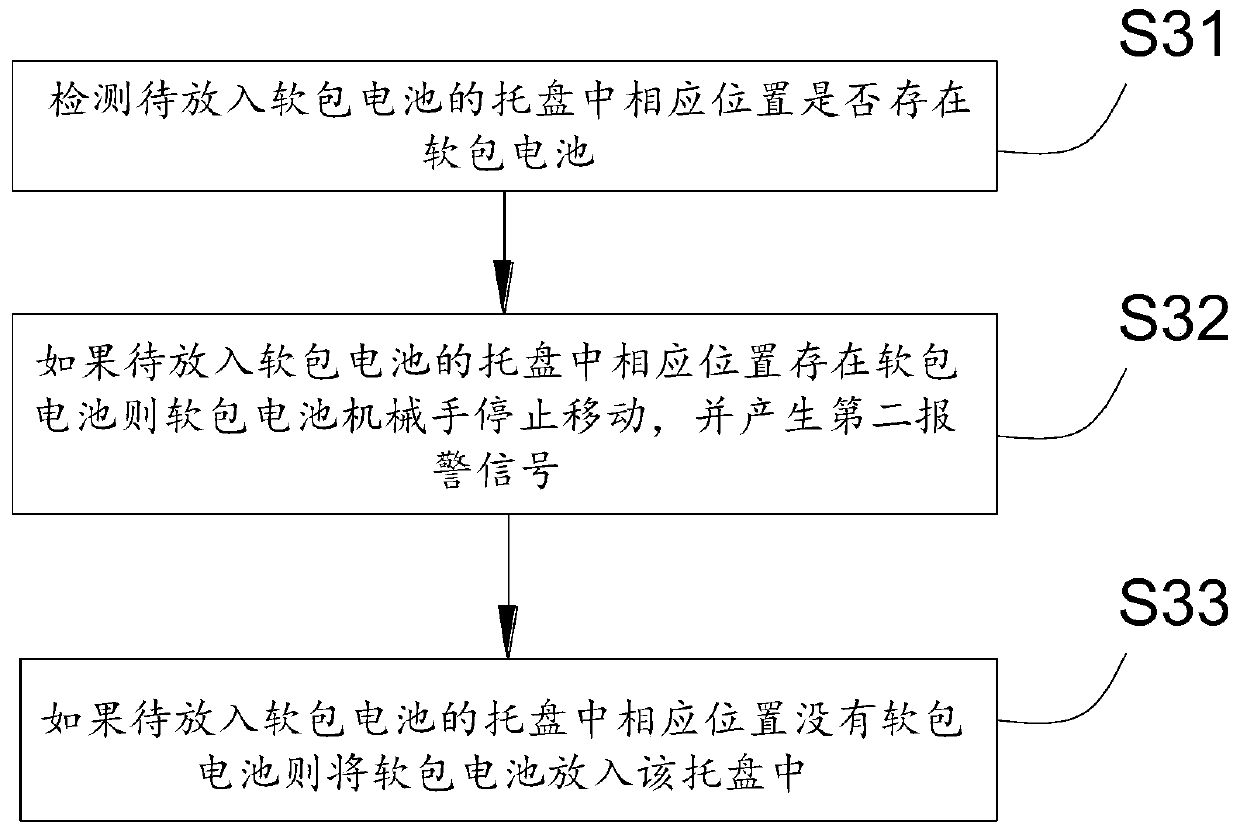

[0044] Such as image 3 As shown, this embodiment provides a method for replacing and loading soft-pack batteries, and the step S3 also includes:

[0045] S31. Detect whether there is a pouch battery 30 at a corresponding position in the tray to be put into the pouch battery 30;

[0046] S32. If there is a pouch battery 30 in the corresponding position of the tray to be put into the pouch battery 30, the manipulator of the pouch battery 30 stops moving and generates a second alarm signal;

[0047] S33. If there is no pouch battery 30 in the corresponding position of the tray to be put into the pouch battery 30, put the pouch battery 30 into the tray.

[0048] In this embodiment, before putting the pouch battery 30 into the tray of the next process, it is first detected whether there is a pouch battery 30 at the corresponding placement position in the tray to be put into the pouch battery 30, if there is already a pouch battery 30 , the loading operation will be suspended and a...

Embodiment 3

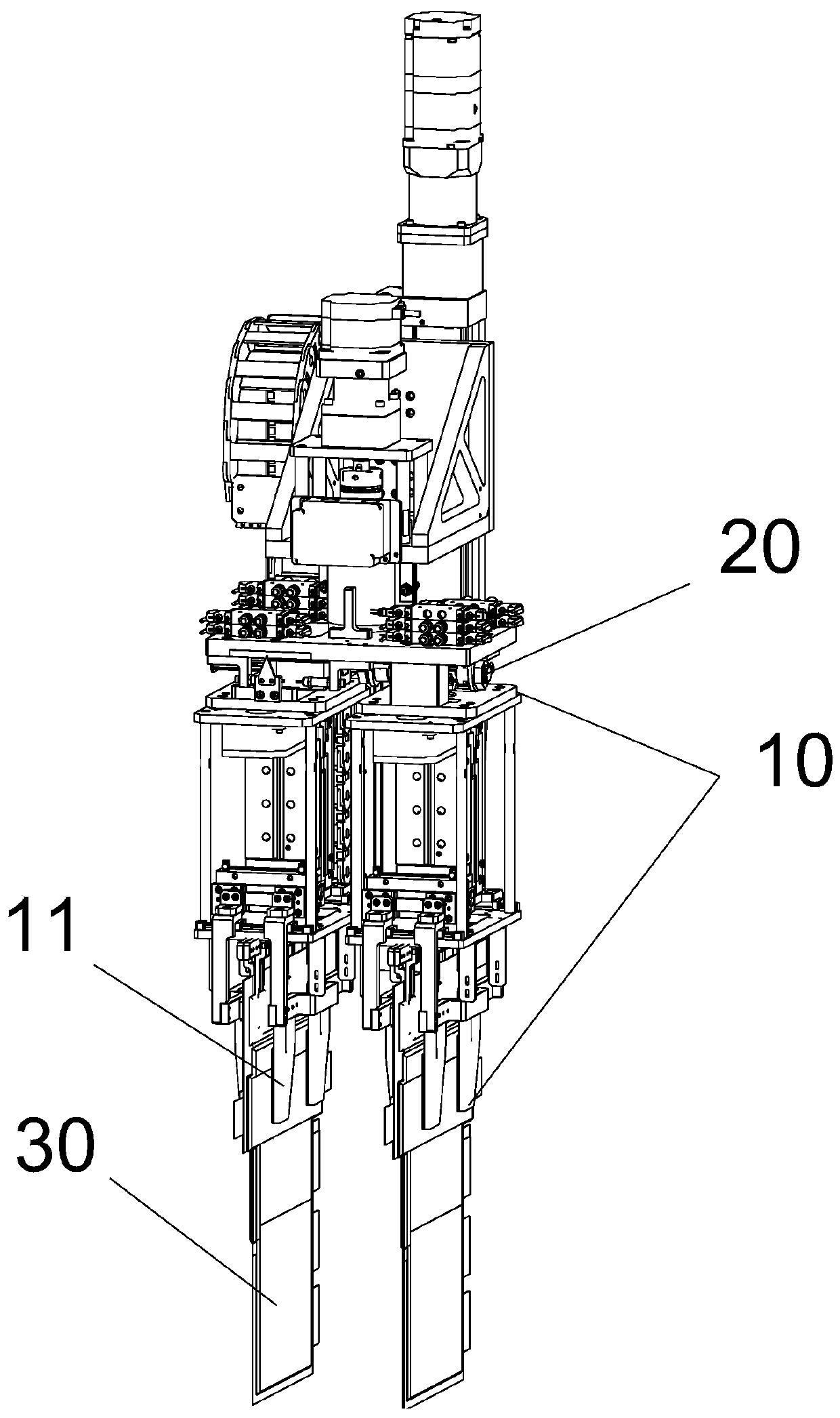

[0055] Such as Figure 4 As shown, in this embodiment, the manipulator of the pouch battery 30 includes a plurality of clamping mechanisms 10 and a distance changing mechanism 20 for adjusting the distance between two adjacent clamping mechanisms 10, before the step S3 Also includes:

[0056] S21. Obtain the battery placement gap between two adjacent pouch batteries 30;

[0057] S22. Determine the corresponding station spacing according to the acquired battery placement gap;

[0058] S23. Control the pitch-changing mechanism 20 according to the station distance to adjust the distance between corresponding two adjacent clamping mechanisms 10 .

[0059] The battery placement gap can be input to the controller of the manipulator by the operator, and the controller determines the corresponding station spacing according to the battery placement gap, and generates a corresponding control signal, and controls the pitch-changing mechanism 20 to adjust the phase connected to it by st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com