Treatment device and method for molten iron splash in blast furnace taphole duct

A treatment device and treatment method technology, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems of poor adaptability of on-site disposal, impracticability, and the need to increase the number of tapping times, so as to solve the problem of tapping spatter , flexible and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Combined with the effective volume below 2650m 3 Blast Furnace A method for treating molten iron splashing in a blast furnace tap hole of the present application will be described in detail.

[0070] Step 1: Stabilize the depth of the iron hole to be more than 3m, use a ∮55mm drill bit to drill the iron hole to tap iron.

[0071] Step 2: After the blast furnace has tapped the iron, use the first mud gun to drive the first production gun mud into the iron hole of the blast furnace. The mud was sintered for 30 minutes, and the operation of pulling out the cannon was carried out.

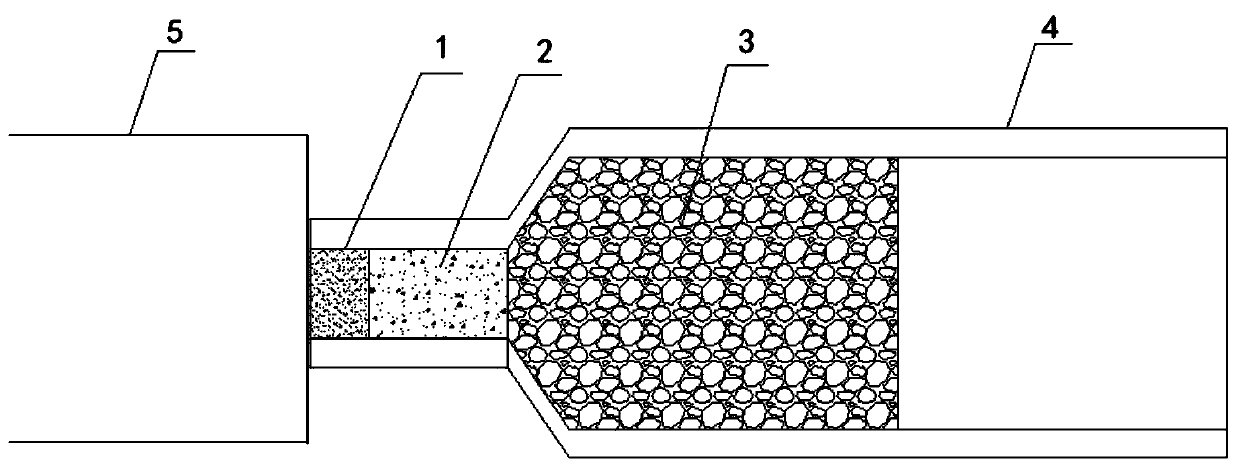

[0072] Step 3: Fill the second mud gun 4 with the second production mud 3, take out the second production mud 3 at the front of the gun head, fill in 30 kg of anhydrous slurry 2, and seal it with 5 kg of water mud 1 The gun head prevents the anhydrous slurry 2 from flowing out when the gun is blocked. The weight ratio of the water taphole mud, the anhydrous slurry and the second production ta...

Embodiment 2

[0080] Combined with the effective volume below 2650m 3 Blast Furnace A method for treating molten iron splashing in a blast furnace tap hole of the present application will be described in detail.

[0081] Step 1: Stabilize the depth of the iron hole to be more than 3m, use a ∮50mm drill bit to drill the iron hole to tap iron.

[0082] Step 2: After the blast furnace has finished ironing, use the first mud gun to drive the first production gun mud into the blast furnace iron mouth hole. Sinter for 30min, then pull out the cannon.

[0083]Step 3: Fill the second mud gun 4 with the second production mud 3, take out the second production mud 3 at the front of the gun head, then put 35 kg of anhydrous slurry 2, and then pack 5 kg of water mud Block the gun head to prevent the anhydrous slurry 2 from flowing out when the gun is blocked. The weight ratio of the water taphole mud, the anhydrous slurry and the second production taphole mud is 5:35:360.

[0084] Step 4: Drilling a...

Embodiment 3

[0090] Combined with the effective volume below 2650m 3 Blast Furnace A method for treating molten iron splashing in a blast furnace tap hole of the present application will be described in detail.

[0091] Step 1: Stabilize the depth of the iron hole to be more than 3m, use a ∮53mm drill bit to drill the iron hole to tap iron.

[0092] Step 2: After the blast furnace has tapped the iron, use the first mud gun to drive the first production gun mud into the iron hole of the blast furnace. The mud was sintered for 30 minutes, and the operation of pulling out the cannon was carried out.

[0093] Step 3: Fill the second mud gun 4 with the second production mud 3, take out the second production mud 3 at the front of the gun head, then put 35 kg of anhydrous slurry 2, and then pack 5 kg of water mud Block the gun head to prevent the anhydrous slurry 2 from flowing out when the gun is blocked. The weight ratio of the water taphole mud, the anhydrous slurry and the second productio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com