A kind of anti-oxidation copper wire annealing method

An anti-oxidation, copper wire technology, applied in furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of copper wire oxidation and blackening, inability to continue to carry alcohol, and high failure rate of steam generators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] Select a copper wire with a diameter of 0.05mm for the following steps:

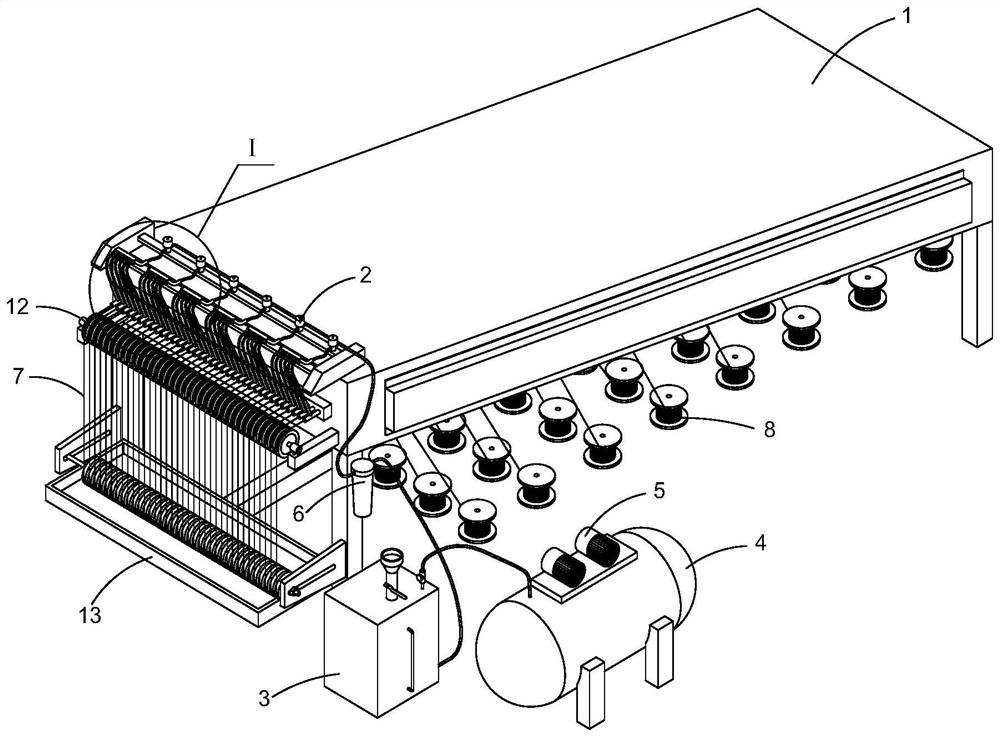

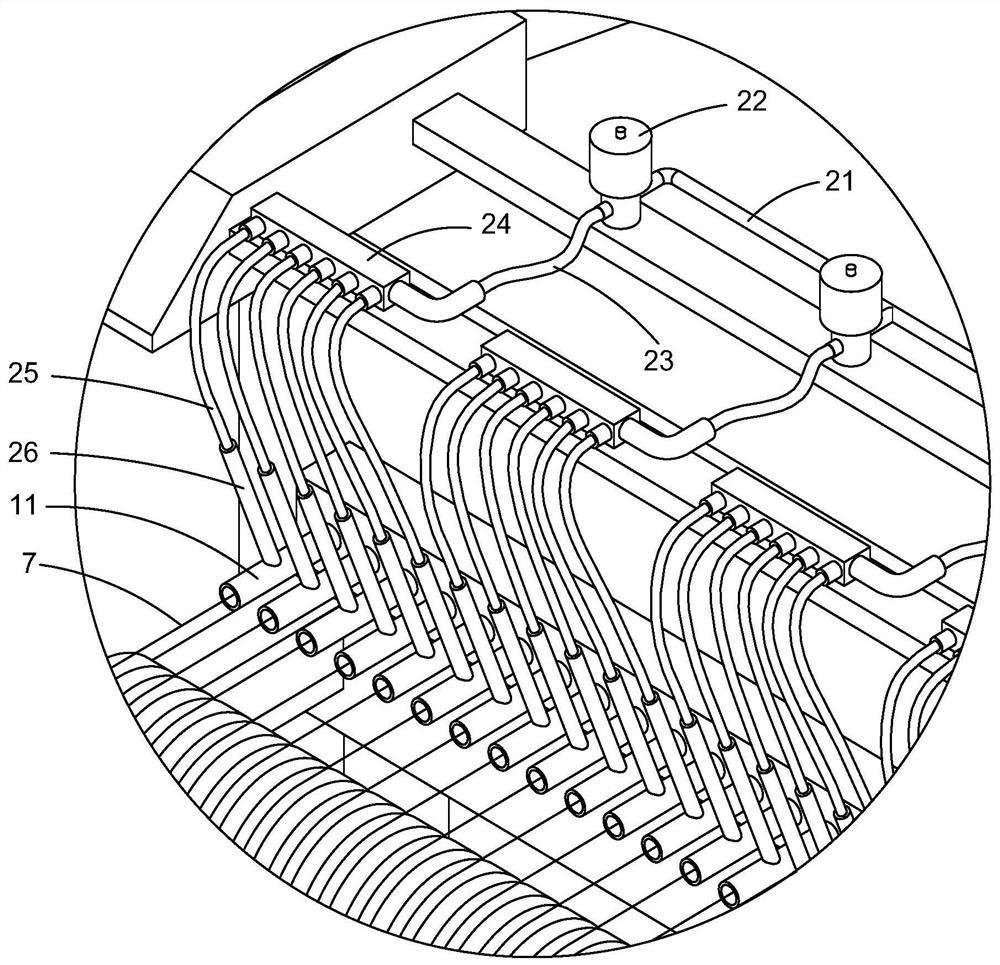

[0092] Step 1. Threading: pass the copper wire 7 to be annealed through the annealing tube 11 after being reversed by the roller 12 and lead it to the take-up reel;

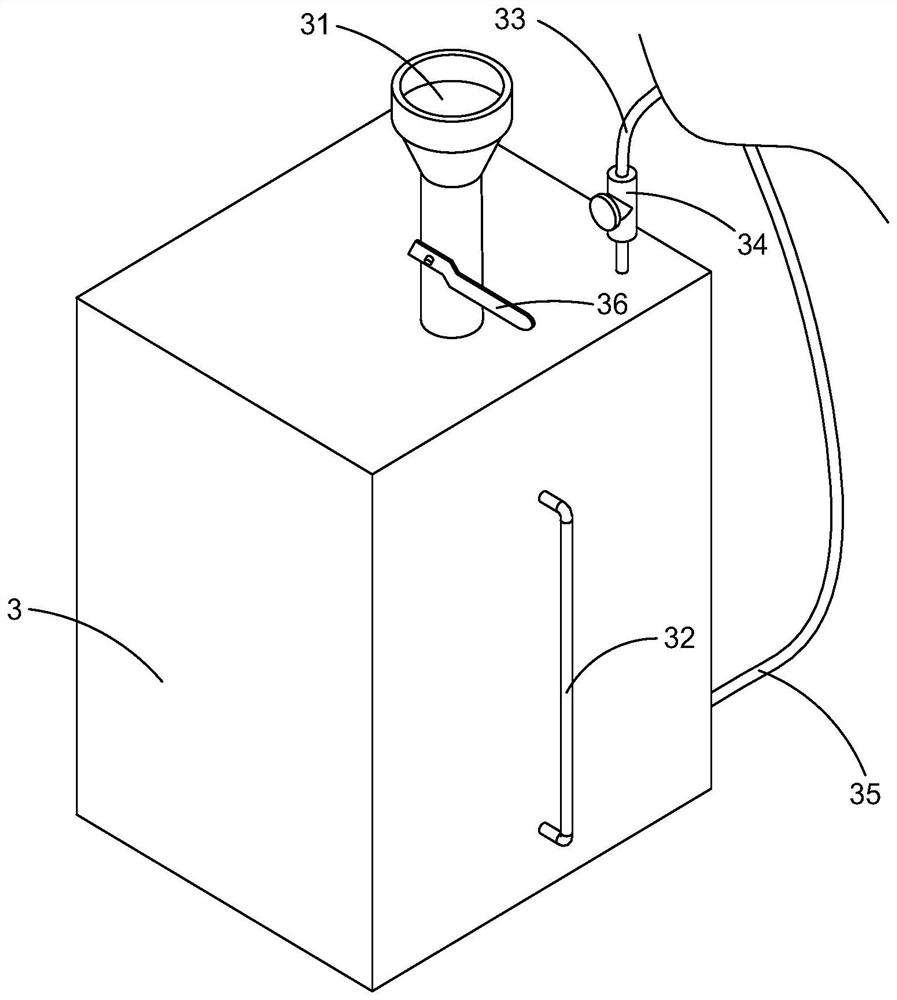

[0093] Step 2, pre-spraying: spraying an ethanol aqueous solution with a concentration of 5% into the annealing tube 11, the spraying time is 2s, and the spraying amount is 2ml / s;

[0094] Step 3, annealing: make the copper wire 7 pass through the annealing furnace at a speed of 5m / s, the temperature distribution of the annealing furnace is: 385°C for 0m-3m, 385°C for 3m-6m, and 385°C for more than 6m;

[0095] Step 4, spraying: when a certain copper wire stops in step 3, the controller 9 opens the electromagnetic valve 22, and uses the compressed air in the air bottle 4 to squeeze out the 5% ethanol aqueous solution in the liquid storage tank 3, Spray into the corresponding annealing tube, control the spraying interval to 120s, the...

Embodiment 2

[0100] Select a copper wire with a diameter of 0.8mm for the following steps:

[0101] Step 1. Threading: pass the copper wire 7 to be annealed through the annealing tube 11 after being reversed by the roller 12 and lead it to the take-up reel;

[0102] Step 2, pre-spraying: spraying an ethanol aqueous solution with a concentration of 10% into the annealing tube 11, the spraying time is 2s, and the spraying amount is 2ml / s;

[0103] Step 3, annealing: make the copper wire 7 pass through the annealing furnace at a speed of 1m / s, and the temperature distribution of the annealing furnace is: 660°C for 0m-3m, 660°C for 3m-6m, and 660°C for more than 6m;

[0104] Step 4, spraying: when a certain copper wire is stopped in step 3, the controller 9 opens the solenoid valve 22, and uses the compressed air in the air bottle 4 to squeeze out the 10% ethanol aqueous solution in the liquid storage tank 3, Spray into the corresponding annealing tube, control the spraying interval to 120s, th...

Embodiment 3

[0109] Select a copper wire with a diameter of 0.2mm for the following steps:

[0110] Step 1. Threading: pass the copper wire 7 to be annealed through the annealing tube 11 after being reversed by the roller 12 and lead it to the take-up reel;

[0111] Step 2, pre-spraying: spraying an ethanol aqueous solution with a concentration of 7% into the annealing tube 11, the spraying time is 2s, and the spraying amount is 2ml / s;

[0112] Step 3, annealing: make the copper wire 7 pass through the annealing furnace at a speed of 4m / s, and the temperature distribution of the annealing furnace is: 565°C for 0m-3m, 565°C for 3m-6m, and 565°C for more than 6m-6.6m;

[0113] Step 4, spraying: when a certain copper wire stops in step 3, the controller 9 opens the solenoid valve 22, and uses the compressed air in the air bottle 4 to squeeze out the 7% ethanol aqueous solution in the liquid storage tank 3, Spray into the corresponding annealing tube, control the spraying interval to 120s, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com