High-air-permeability environment-friendly regenerated fiber and preparation technology thereof

A regenerated fiber and air permeability technology, which is applied in the field of high air permeability and environment-friendly regenerated fiber and its preparation process, can solve the problems of poor air permeability of regenerated fiber materials, inability to degrade regenerated fiber materials, and unsatisfactory product quality, so as to improve elasticity, The effect of improving flexibility and increasing elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

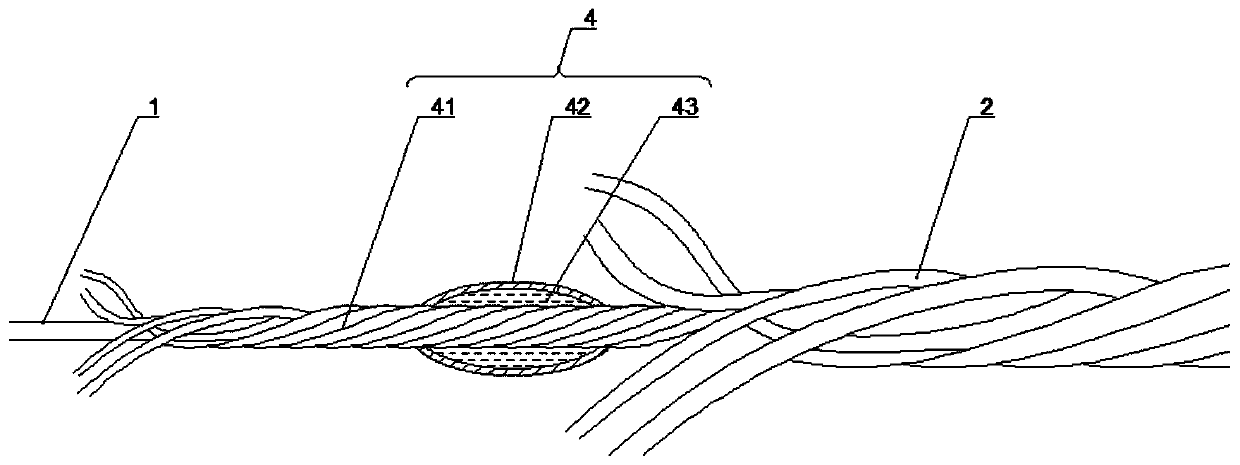

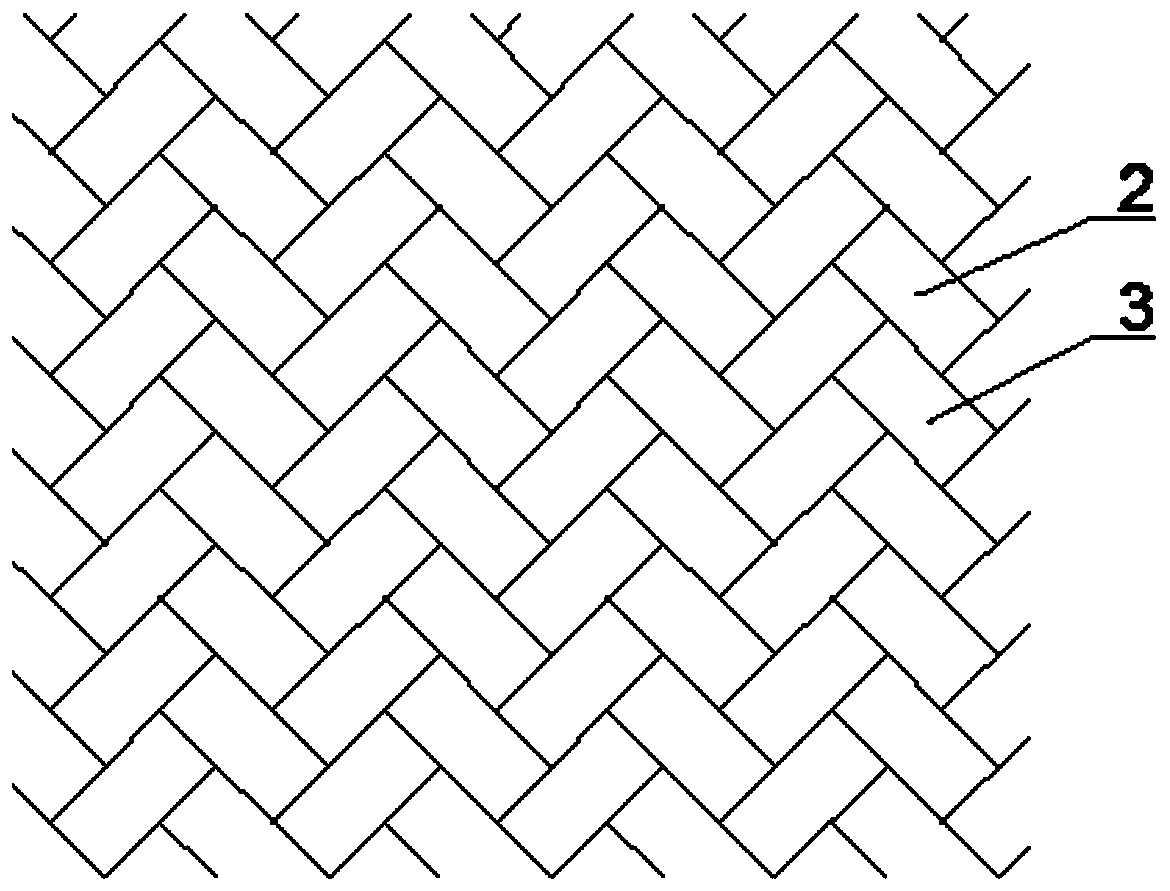

[0038] Such as Figure 1-6 A highly air-permeable environment-friendly regenerated fiber shown includes: a core layer 1, an outer covering layer 2, a breathable layer 3 and an elastic layer 4, an elastic layer 4 is arranged on the outside of the core layer 1, and the elastic layer 4 wraps A core layer 1, an outer cover layer 2 is arranged on the outside of the elastic layer 4, and the outer cover layer 2 wraps the elastic layer 4, and a breathable layer 3 is arranged on one side of the outer cover layer 2, and the breathable layer 3 and the outer cover Layer 2 cross weave arrangement;

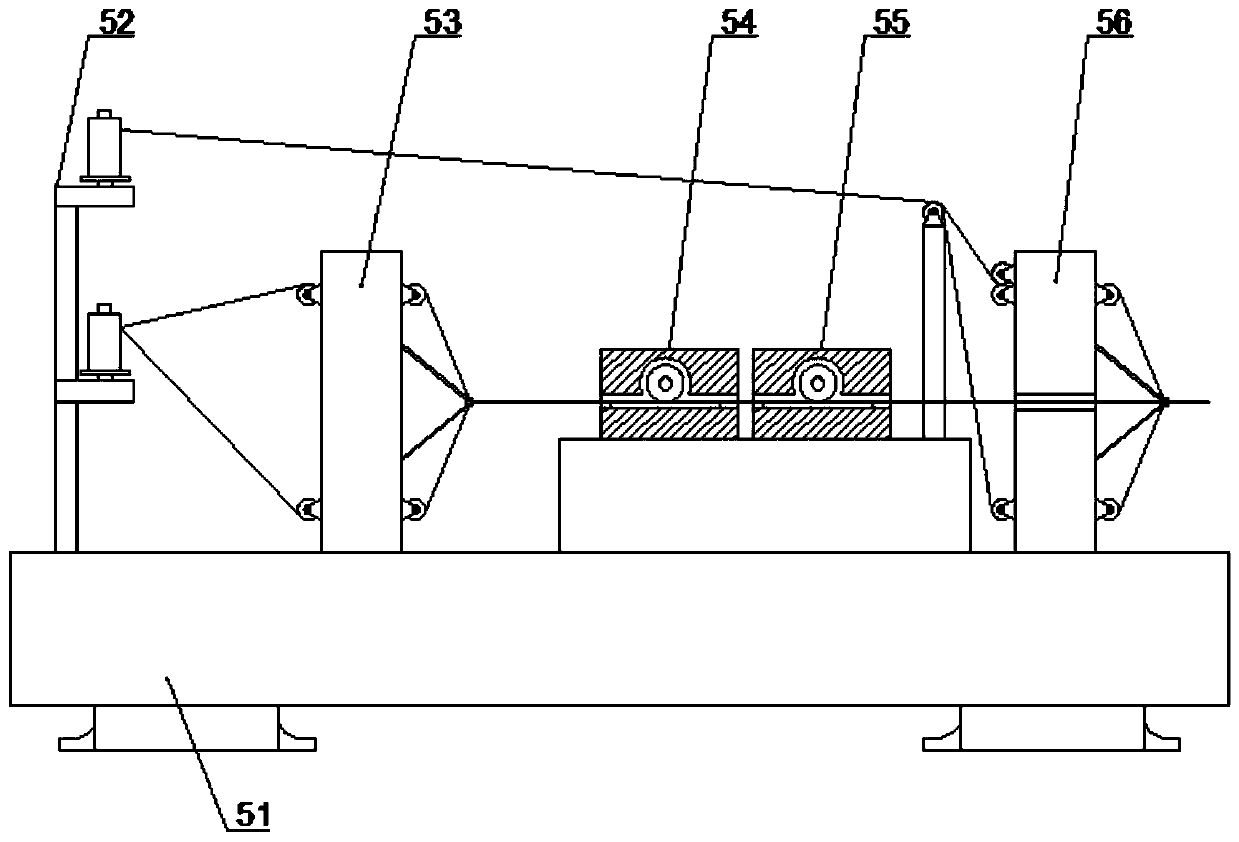

[0039] The above-mentioned preparation method of a highly air-permeable environment-friendly regenerated fiber includes preparing raw materials, twisting wires into wires and weaving and forming, specifically including the following steps:

[0040] Step 1: preparing raw materials, preparing core layer 1 wires, outer covering layer 2 wires, breathable layer 3 wires and elastic layer 4 wires by ...

Embodiment 2

[0052] Such as figure 1 and 2 A highly air-permeable environment-friendly regenerated fiber shown includes: a core layer 1, an outer covering layer 2, a breathable layer 3 and an elastic layer 4, an elastic layer 4 is arranged on the outside of the core layer 1, and the elastic layer 4 wraps A core layer 1, an outer cover layer 2 is arranged on the outside of the elastic layer 4, and the outer cover layer 2 wraps the elastic layer 4, and a breathable layer 3 is arranged on one side of the outer cover layer 2, and the breathable layer 3 and the outer cover Layer 2 cross weave arrangement;

[0053] The above-mentioned preparation method of a highly air-permeable environment-friendly regenerated fiber includes preparing raw materials, twisting wires into wires and weaving and forming, specifically including the following steps:

[0054] Step 1: preparing raw materials, preparing core layer 1 wires, outer covering layer 2 wires, breathable layer 3 wires and elastic layer 4 wires...

Embodiment 3

[0062] Such as figure 1 , 3 , a kind of highly air-permeable environment-friendly regenerated fiber shown in 4, 5 and 6, comprising: a core layer 1, an outer covering layer 2, a breathable layer 3 and an elastic layer 4, and an elastic layer 4 is arranged on the outside of the core layer 1, The elastic layer 4 wraps the core layer 1, and an outer covering layer 2 is arranged on the outer side of the elastic layer 4, and the outer covering layer 2 wraps the elastic layer 4, and a breathable layer 3 is arranged on one side of the outer covering layer 2, and the outer covering layer 2 is provided with a breathable layer 3. The air-permeable layer 3 and the outer cover layer 2 are cross-woven;

[0063] The above-mentioned preparation method of a highly air-permeable environment-friendly regenerated fiber includes preparing raw materials, twisting wires into wires and weaving and forming, specifically including the following steps:

[0064] Step 1: preparing raw materials, prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com