Combined abutment structure for temporary trestle

A combined trestle technology, applied in bridge form, portable bridge, infrastructure engineering, etc., can solve problems such as vertical deformation of trestle structure, inconvenient on-site construction and installation, and road surface cracking, so as to improve overall rigidity and stability, The effect of fast construction speed and shortened cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

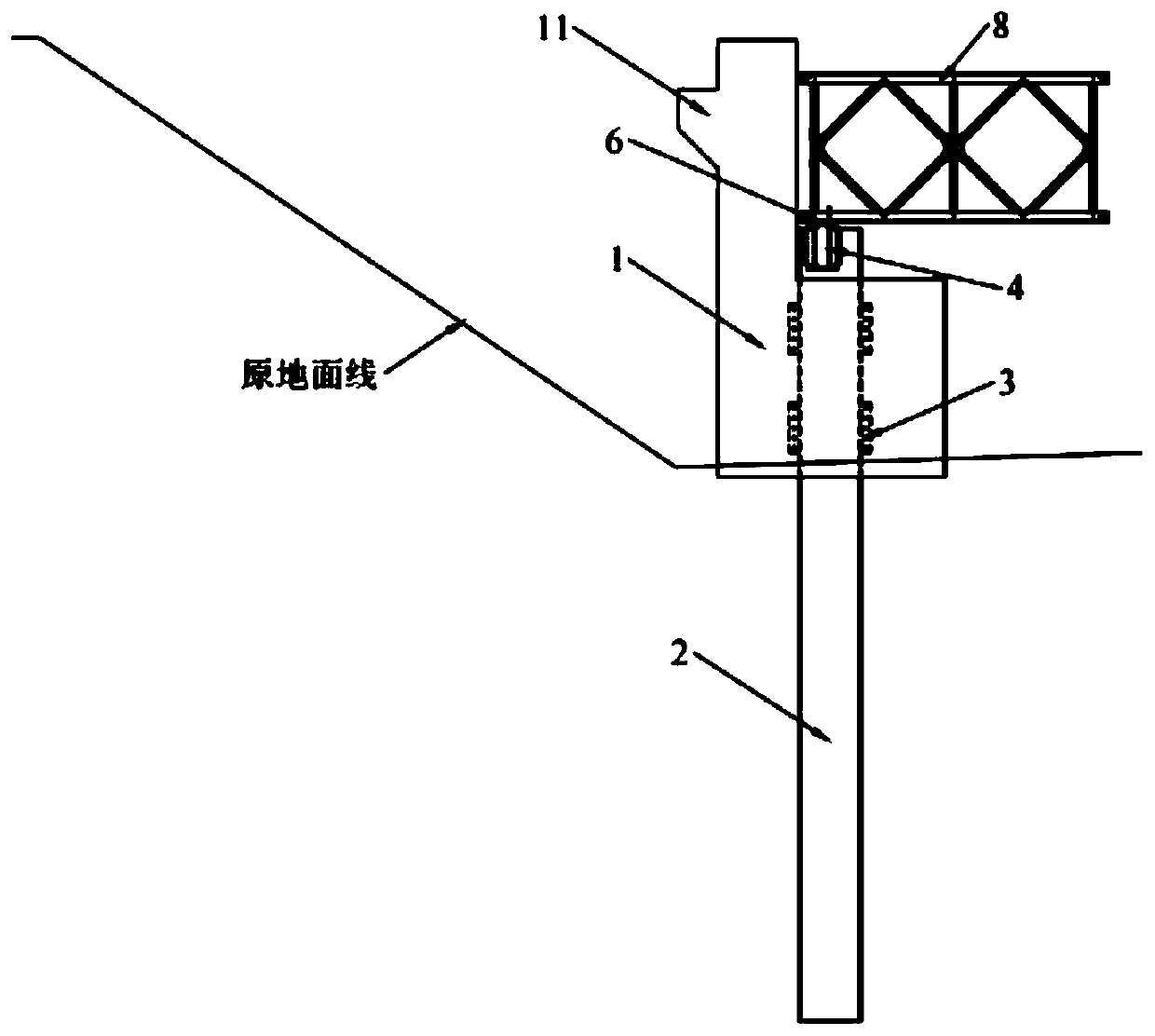

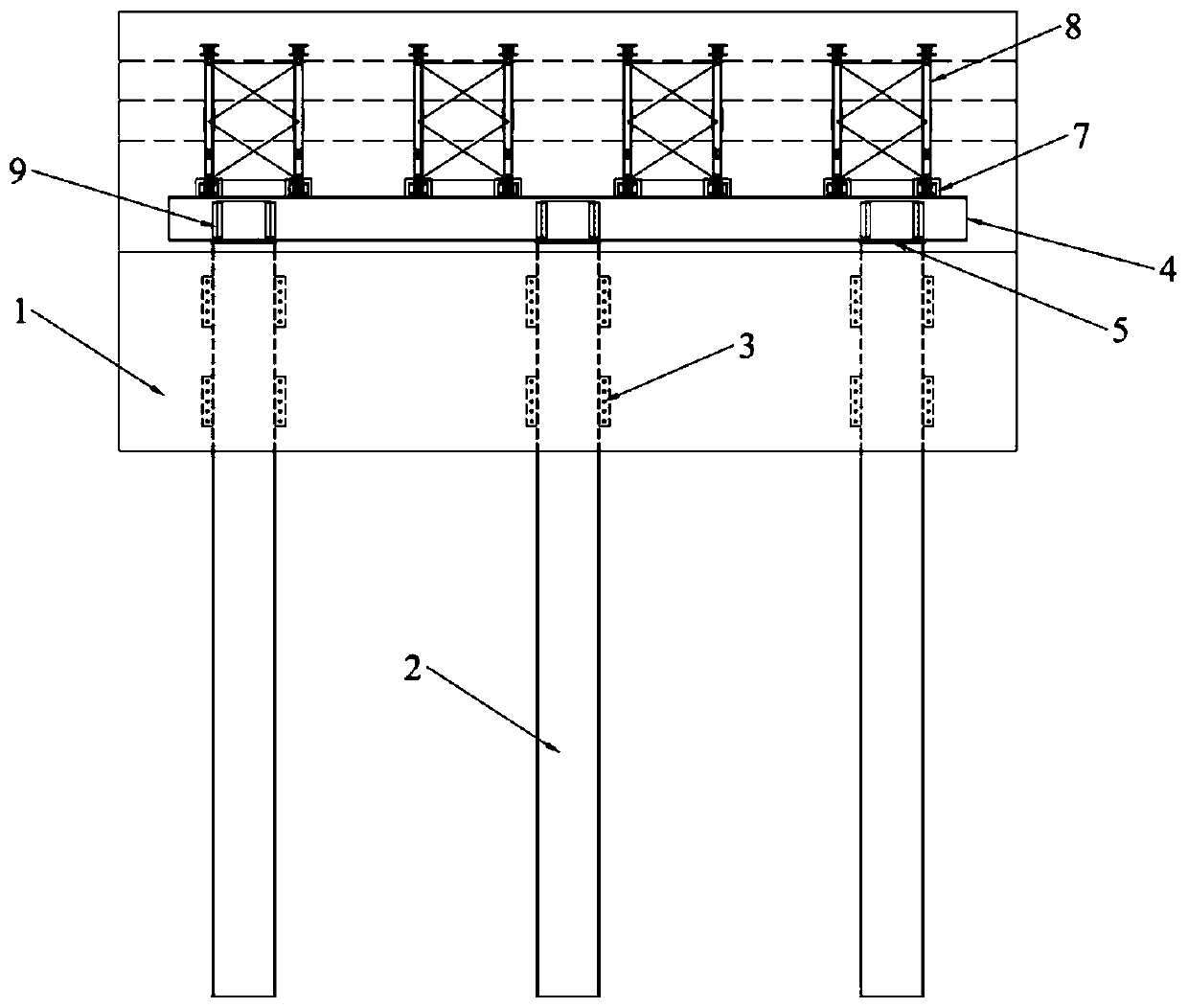

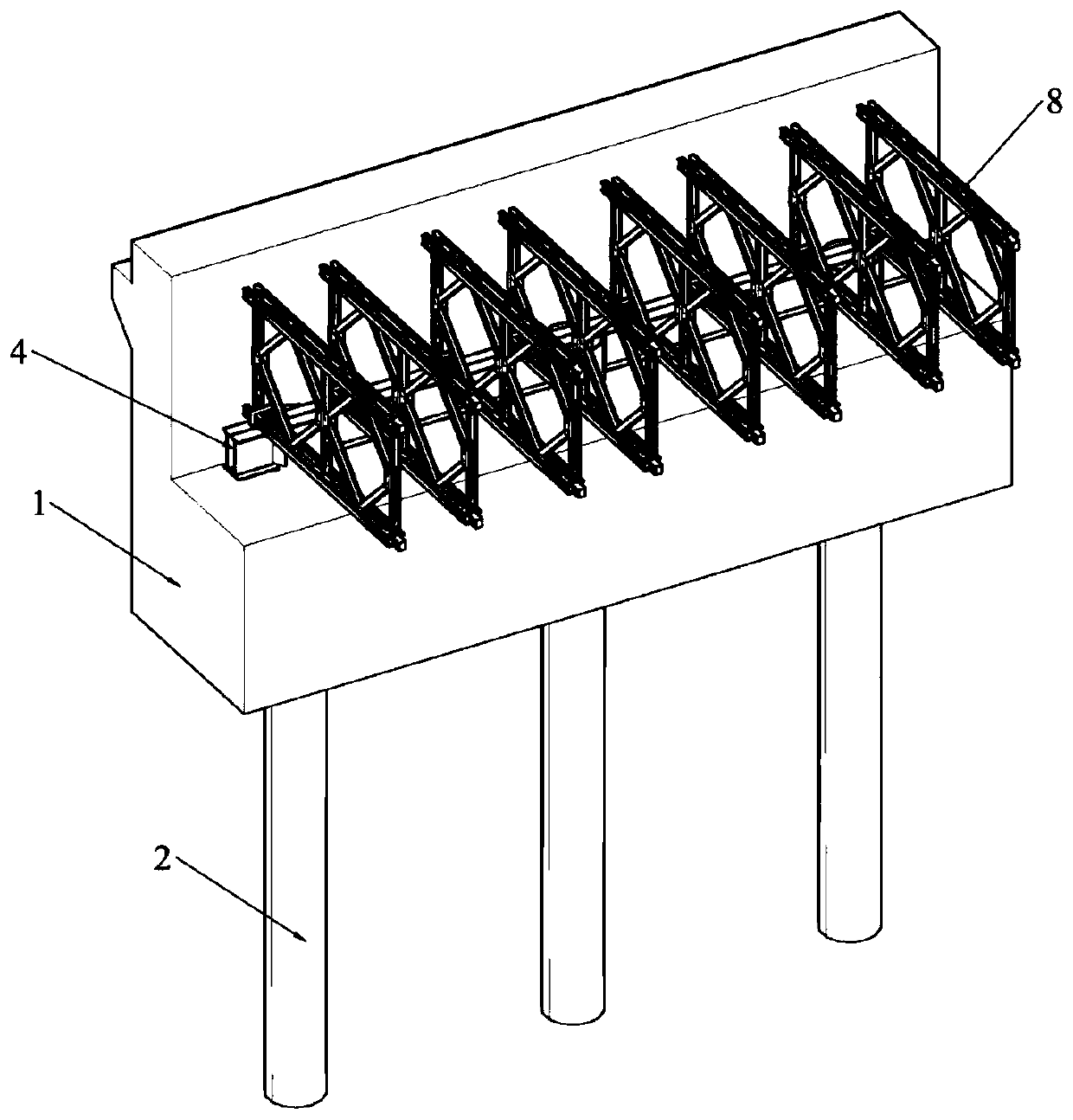

[0025] like Figure 1-5 As shown, the present invention discloses a combined abutment structure for a temporary trestle, including a pedestal 1, a steel pipe pile 2, a shear connector 3, a backing beam 4, a steel backing plate 5, a rubber pad 6, and The limit plate 7; the steel pipe pile 2 is provided with a shear connector 3 in the embedded section of the pedestal 1; The backing beam 4 is snapped inside, the steel backing plate 5 is set between the bottom surface of the backing beam 4 and the eccentric groove 10, and the rubber pad 6 is set between the top surface of the backing beam 4 and the main beam 8 of the trestle bridge for cushioning and vibration reduction; the backing beam 4 The top surface is provided with a limit plate 7 for fixing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com