Apparatus for applying waterproof paint

A waterproof coating and brushing technology, which is applied in the direction of construction and building construction, can solve the problems of waste, paint waste, and the inability to control the flow rate of paint falling, and achieve the effect of preventing paint from overflowing and preventing paint from being wasted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

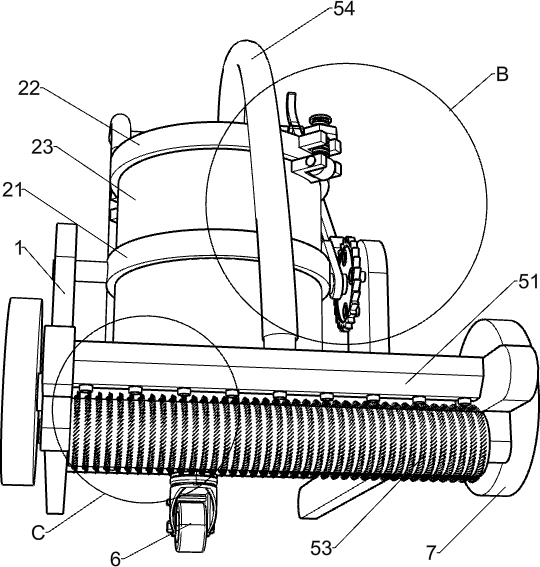

[0025] A waterproof coating brushing device, such as Figure 1-6 As shown, it includes a vehicle frame 1, a material storage structure 2, a push rod 4, a feeding structure 5, a universal wheel 6 and a main wheel 7, and the upper part of the vehicle frame 1 is equipped with a material storage structure 2, and the left and right sides of the vehicle frame 1 front Both sides are rotatably connected with the main wheel 7, the bottom rear side of the vehicle frame 1 is connected with the universal wheel 6, the top rear side of the vehicle frame 1 is connected with the push rod 4, and the front side of the inner wall of the vehicle frame 1 is equipped with a feeding structure 5 , the feeding part of the feeding structure 5 is connected with the storage part of the storage structure 2.

[0026] The material storage structure 2 includes a clamp 21, a bucket cover 22 and a cylinder 23. The left inner wall and the right inner wall of the upper part of the vehicle frame 1 are rotatably c...

Embodiment 2

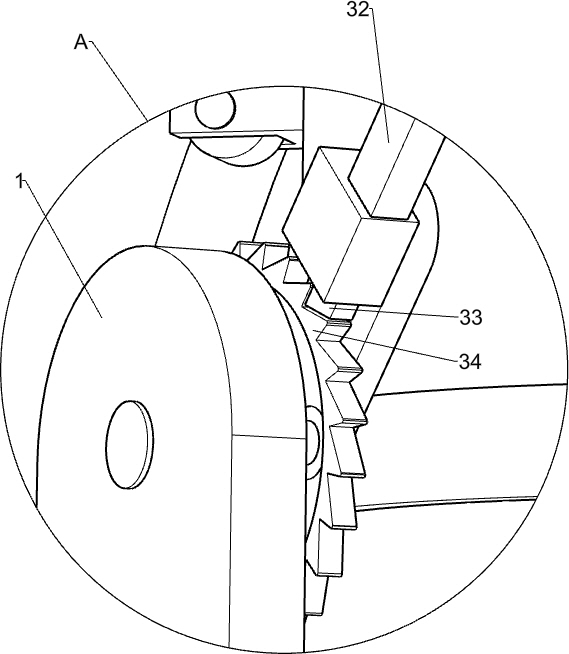

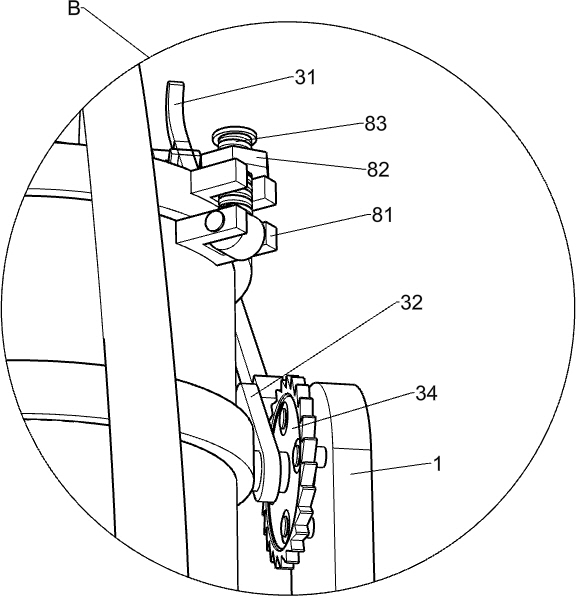

[0030] On the basis of Example 1, such as figure 1 , figure 2 , Figure 4 with Figure 5 As shown, it also includes an angle adjustment device 3, the angle adjustment device 3 includes a pinch 31, an adjustment lever 32, a bayonet 33 and a ratchet 34, the right side inner wall of the vehicle frame 1 top is fixedly connected with a ratchet 34, the rotation of the right side The shaft runs through the ratchet wheel 34, and the rotating shaft between the ratchet wheel 34 and the cylinder body 23 is fixedly connected with an adjusting rod 32, and the top end of the adjusting rod 32 is hingedly connected with a pinch handle 31, and the bottom end of the pinch handle 31 is connected with a bayonet pin 33, and the bayonet pin 33 is slidably connected with the adjusting rod 32, and the bayonet 33 cooperates with the ratchet 34.

[0031] Initially, the detent 33 is locked on the ratchet 34 . When the barrel 23 is to be turned over to make it tilt, manually press the pinch 31 to di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com