High-efficiency tunnel cooling vehicle

A high-efficiency, tunnel-based technology, applied in mine/tunnel ventilation, mining equipment, earthwork drilling and mining, etc., can solve problems affecting the efficient operation of construction equipment, affecting construction personnel, and low heat exchange efficiency, achieving simple structure and improved Construction efficiency and cooling effect are obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

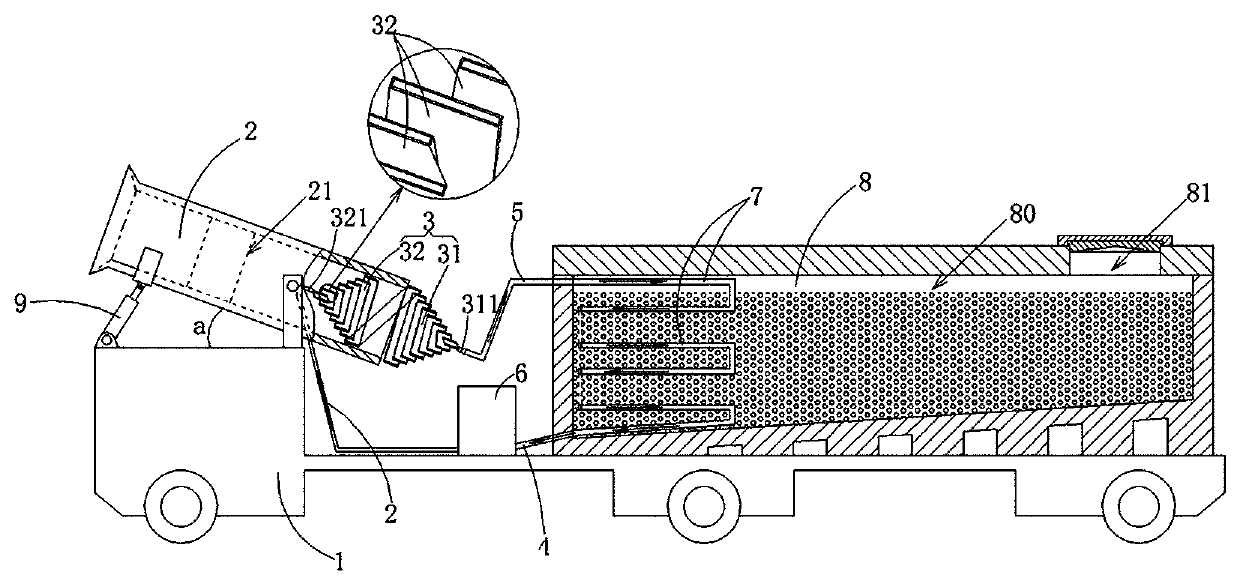

[0018] refer to figure 1 , figure 2 , the high-efficiency tunnel cooling vehicle of the present embodiment, which includes a carrier vehicle 1 and a jet fan 2 assembled on the carrier vehicle 1, an air grid 3, a liquid supply pipe 4, a liquid return pipe 5, a circulation pump 6, and a heat exchanger 7 and closed freezer 8.

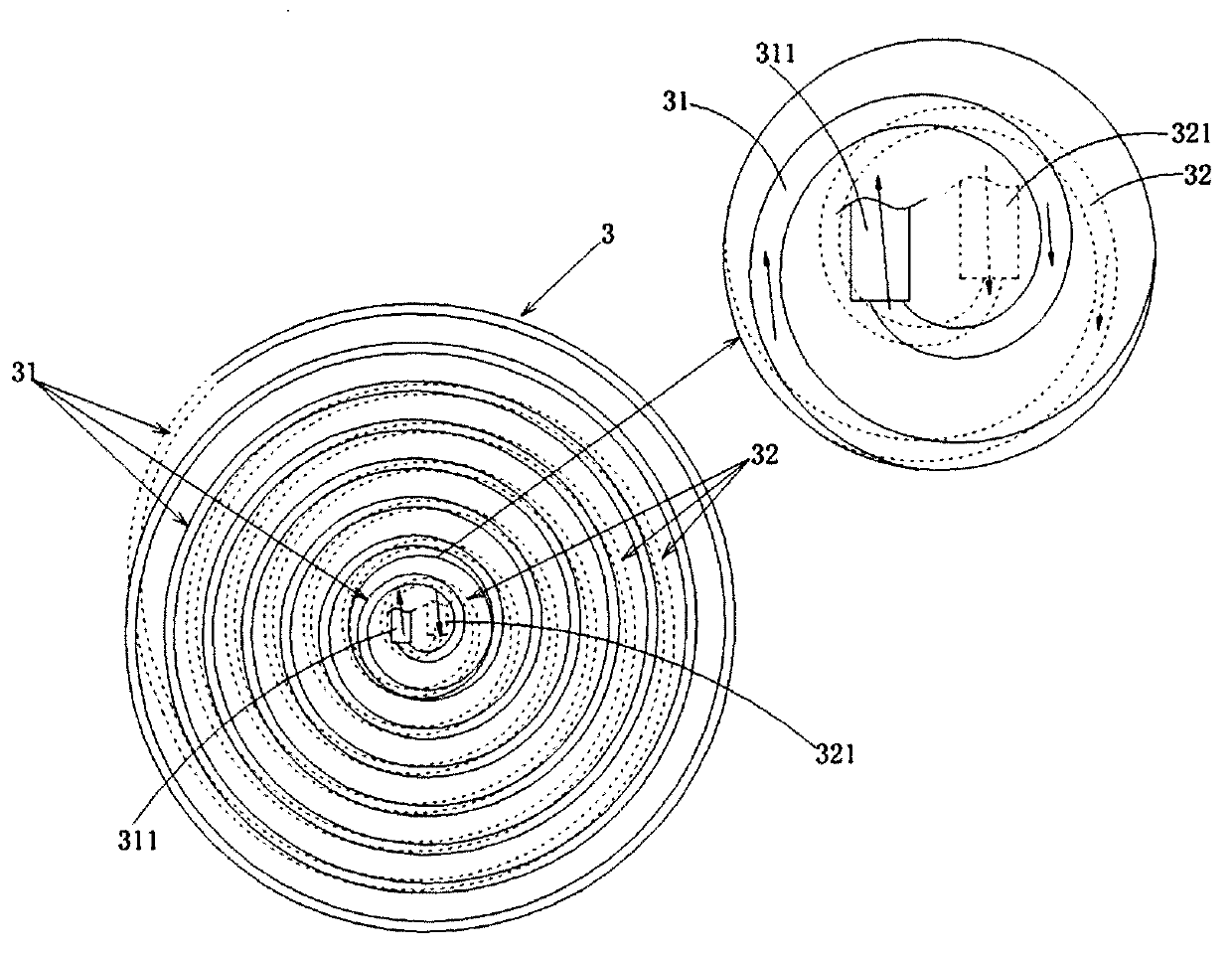

[0019] The above-mentioned air grid 3 includes a pre-cooling air grid 31 and a second cooling air grid 32. The pre-cooling air grid 31 and the second cooling air grid 32 are all formed by a single pipe in a spiral curved conical structure. The liquid outlet of the second cooling air grid 32 is connected to the The liquid inlet end of the pre-cooling air grid 31 is connected and fixedly connected as a whole. The two cooling air grids 32 are fixedly installed inside the air inlet end of the above-mentioned jet fan 2 , and the conica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com