Liquid crystal screen surface liquid leakage detection device and method

A detection device and liquid crystal screen technology, which are applied in the direction of using liquid/vacuum for liquid tightness measurement, and by measuring the acceleration and deceleration rate of fluid, etc., to achieve the effect of preventing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

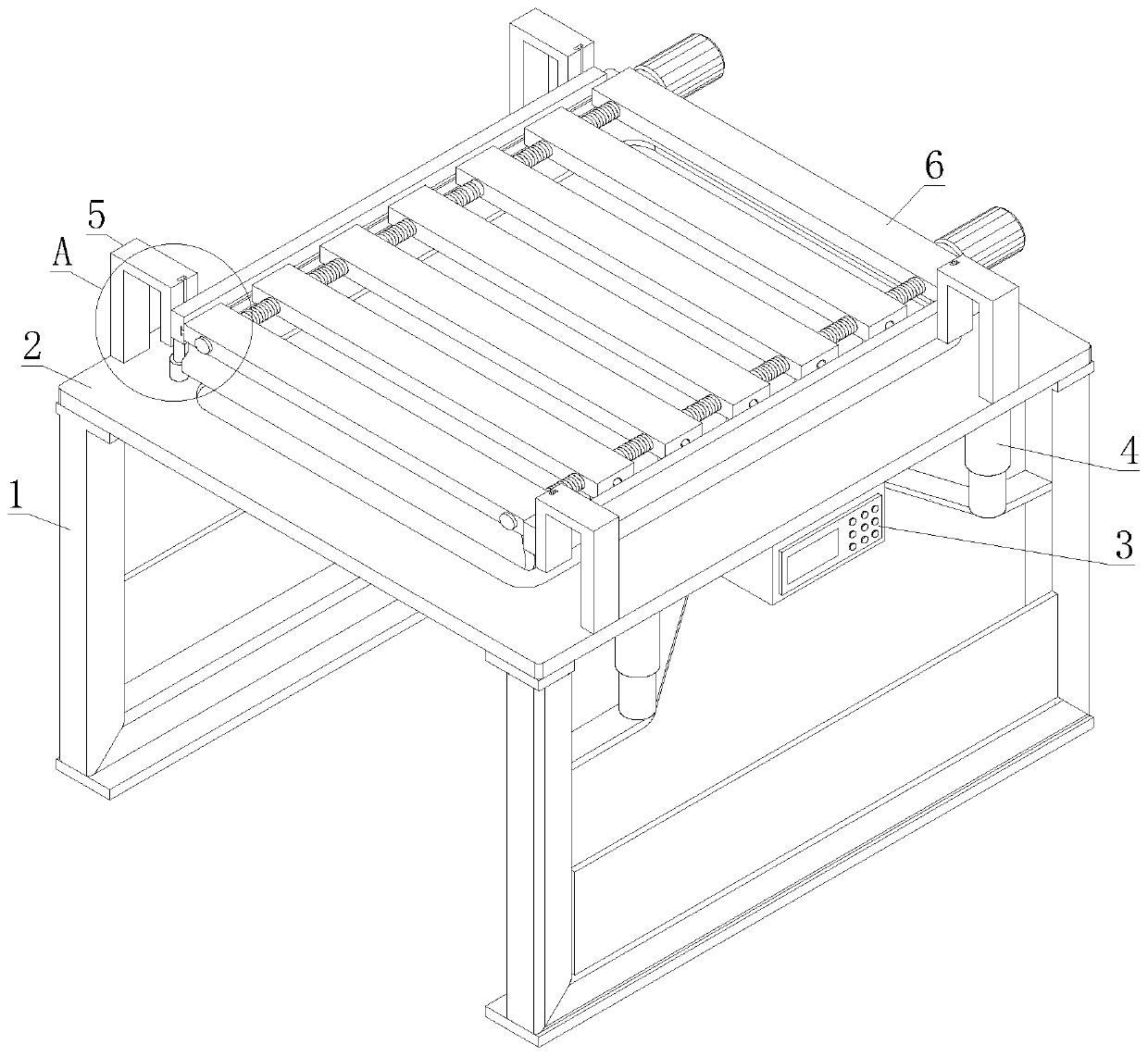

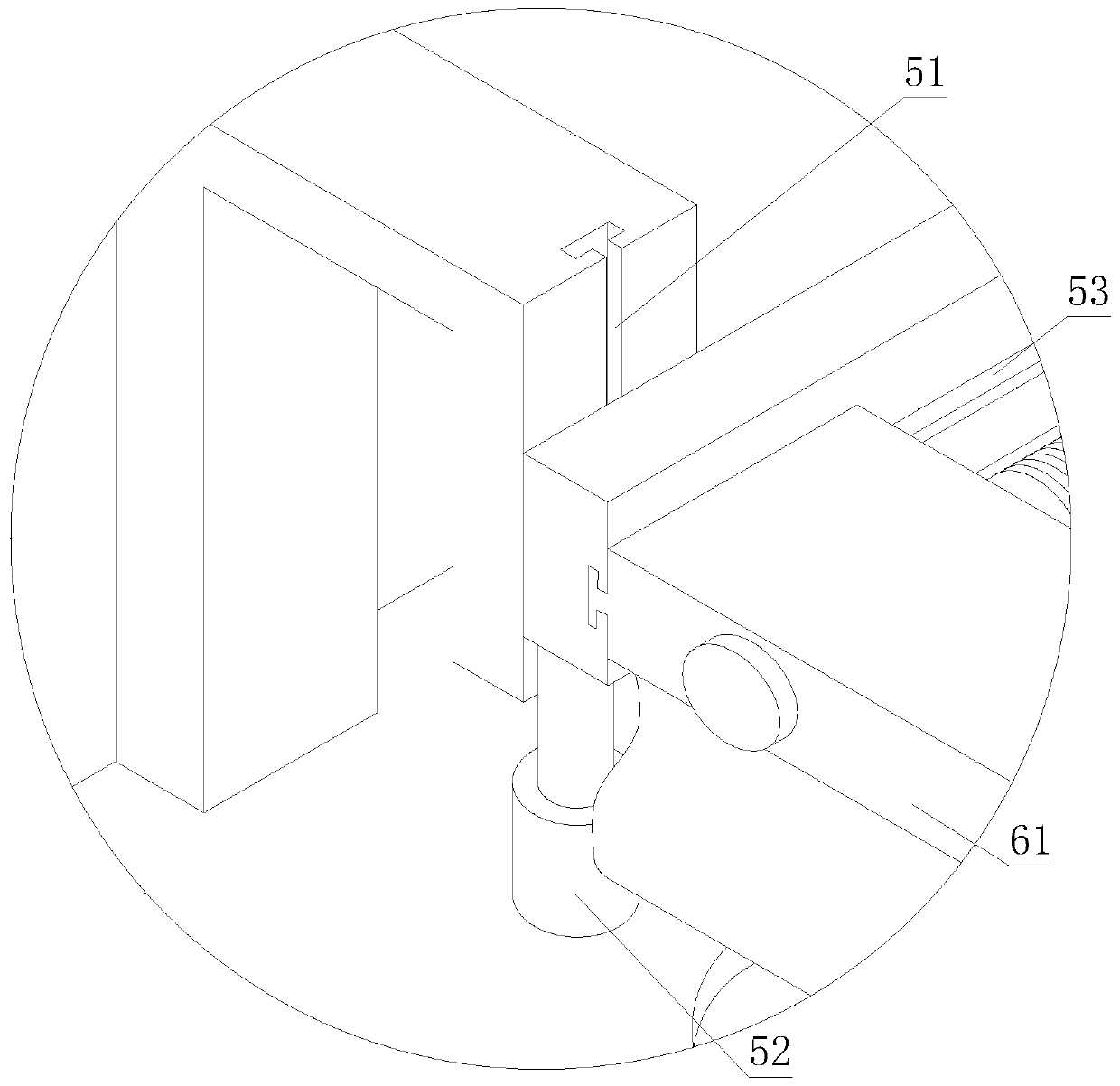

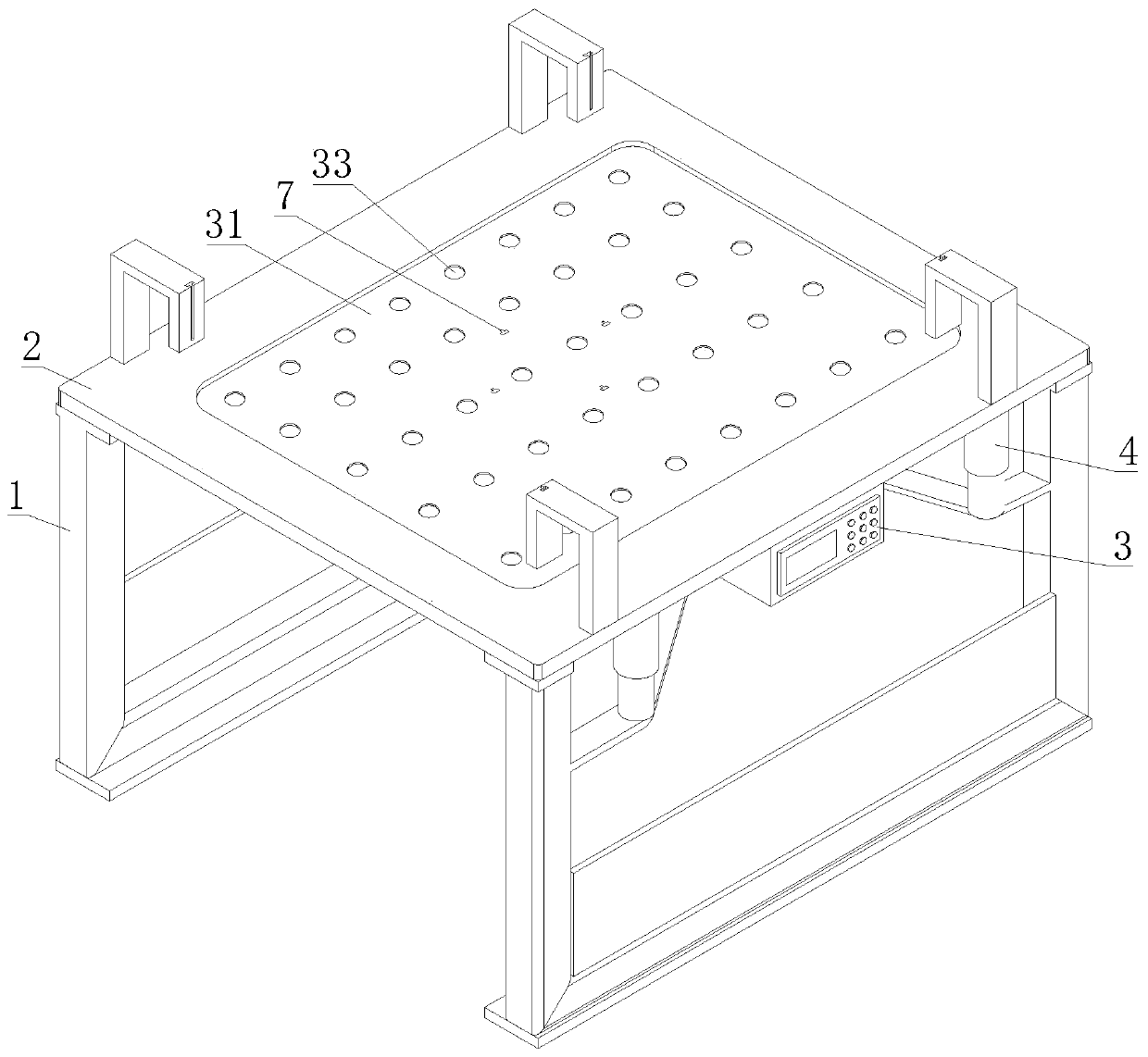

[0030] see Figure 1-4 , a liquid crystal screen surface leakage detection device, including a base 1, a table 2, a fixing mechanism 3, a lifting mechanism 4, a side bracket 5 and an air pressure detection mechanism 6, and the upper four corners of the base 1 are fixedly connected with a ring-shaped table 2 by bolts, A fixing mechanism 3 is slidably connected to the hollow groove in the middle of the table top 2. The upper surface of the fixing mechanism 3 is provided with a gravity sensor 7 and is connected with the lifting mechanism 4. A side bracket 5 is installed on the upper edge of the table top 2. Two side brackets The middle part of 5 is slidably connected with an air pressure detection mechanism 6 , and a gravity sensor 7 is respectively connected with the lifting mechanism 4 and the side bracket 5 .

[0031] The fixing mechanism 3 includes a panel 31 and an air extractor 32, the upper surface of the panel 31 is provided with an air hole 33, the air hole 33 communicat...

Embodiment 2

[0042] see Figure 7-8 The rod body 61 includes a detection unit 611, a rotating motor 612, a second screw 613 and an engaging block 614. A rotating motor 612 is installed on the side wall of the engaging block 614. The rotating motor 612 and the second screw 613 are connected to each other. A plurality of detection units 611 are connected in series, and the plurality of detection units 611 slide along the connecting block 614. The edge of the lower end surface of the detection unit 611 is fixedly connected with a silicone suction cup 64, and a pressure sensor 65 is installed in the middle of the lower end surface of the detection unit 611. A micro-hole 66 is opened, and the micro-hole 66 is connected with the gas-liquid mixing pump.

[0043] see Figure 9 , in order to better show the process of liquid leakage detection on the surface of the liquid crystal screen, the present embodiment now proposes a method for liquid leakage detection on the surface of the liquid crystal s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com