Method for improving photoetching resolution based on space-time collaborative transformation exposure

A lithography resolution, space-time technology, applied in microlithography exposure equipment, photolithography exposure equipment, optics, etc., can solve problems such as large amount of calculation, quantization error, limitation, etc., to achieve accurate control of graphics line width, improve Edge smoothness, the effect of improving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

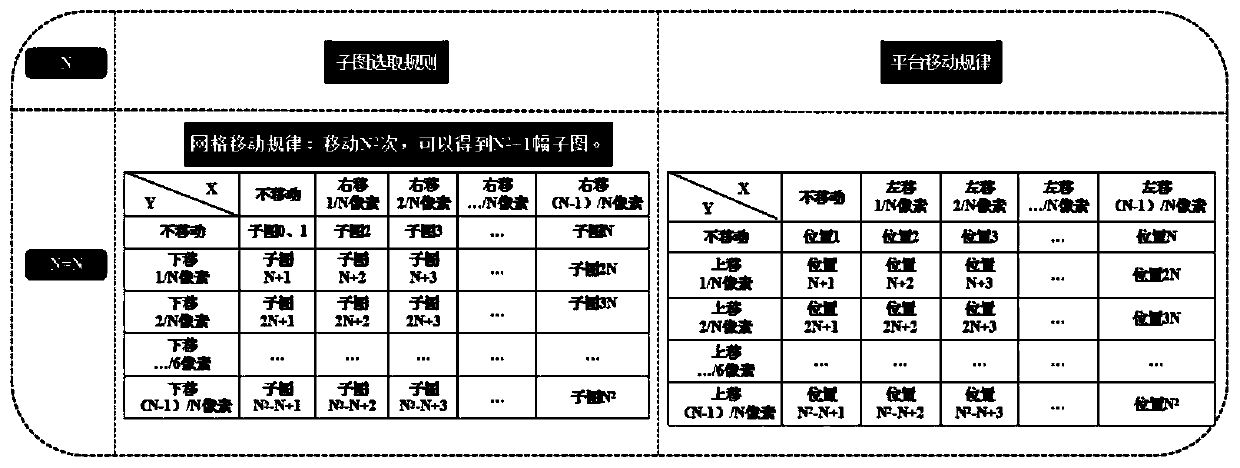

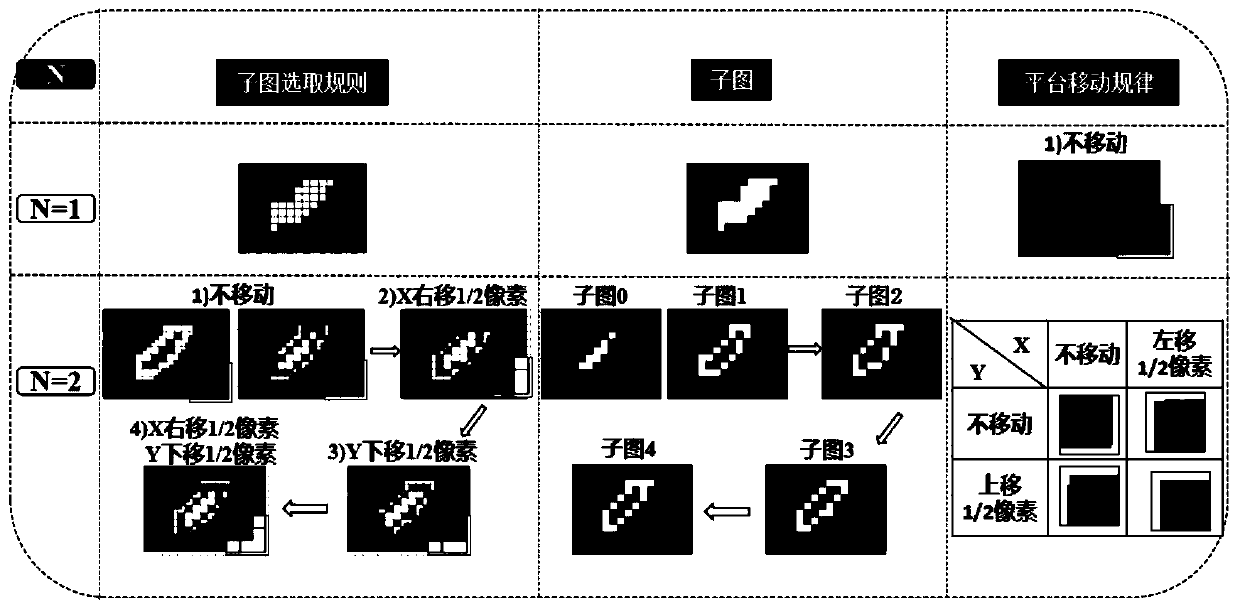

[0042] A method for improving lithography resolution based on spatiotemporal collaborative transformation exposure, comprising the following steps:

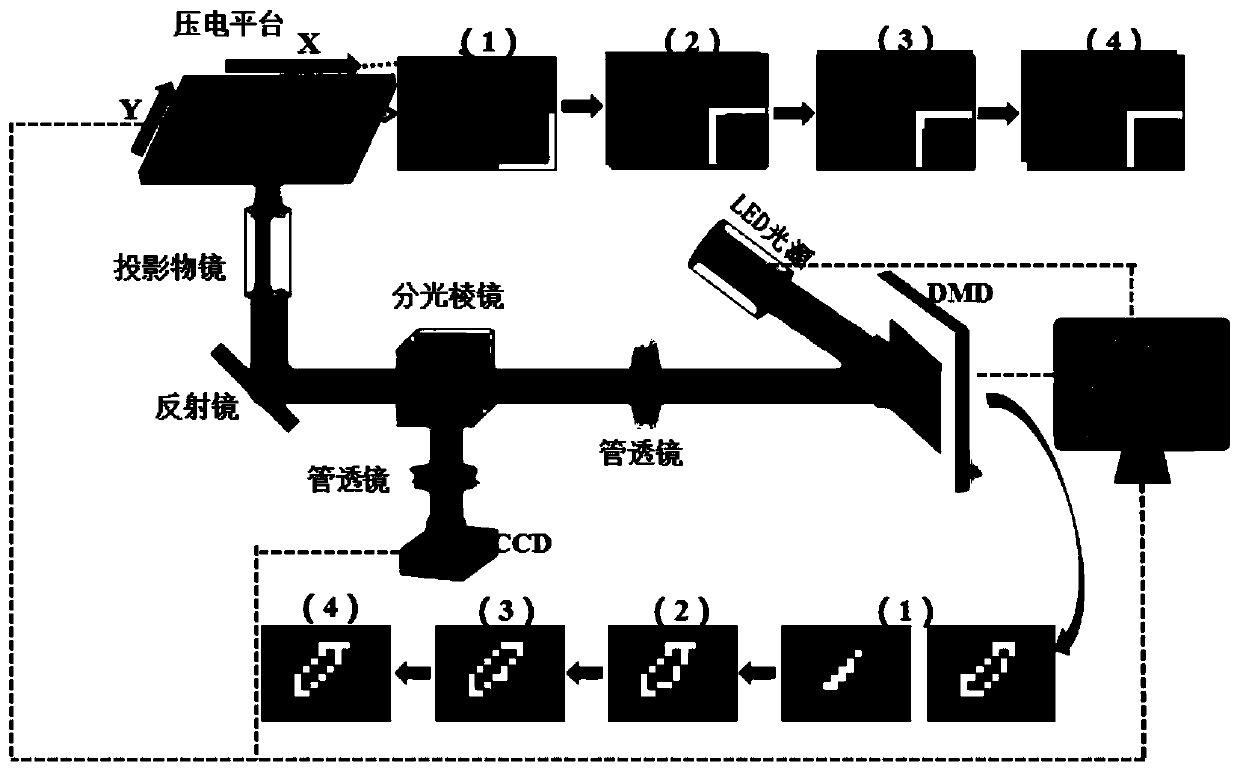

[0043] Step 1, configure the DMD digital lithography system, such as figure 1 As shown, the DMD digital lithography system includes an LED light source, DMD, tube lens, beam splitter, mirror, projection lens, CCD camera and micro-displacement platform, and the light emitted by the LED light source is irradiated to the DMD after being collimated and homogenized. and reflect, and then enter the projection lens after passing through the tube lens, splitter prism, and reflector;

[0044] It should be noted that the micro-displacement platform is a piezoelectric platform.

[0045] Wherein, the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com