Automatic circulator and isolator debugging device

An automatic debugging and isolator technology, which is applied in the direction of waveguide devices, transmission monitoring, electrical components, etc., can solve the problems of uncertain charging and demagnetization times, high cost, and small structural size, so as to reduce the frequency of magnetic adjustment and improve production Efficiency, to achieve the effect of spiral

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to describe technical characterictic of the present invention and realized purpose and effect in detail, further describe below in conjunction with accompanying drawing:

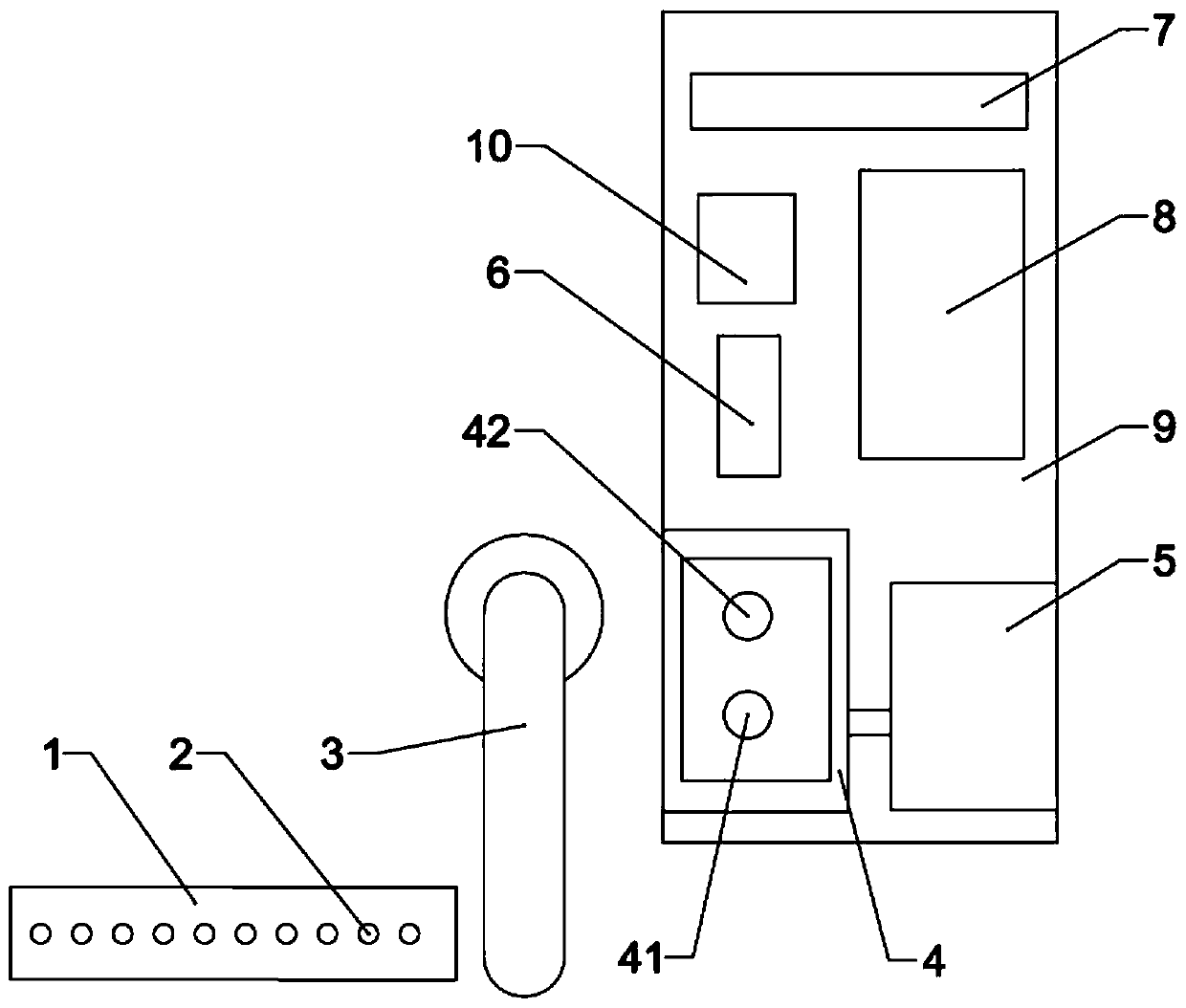

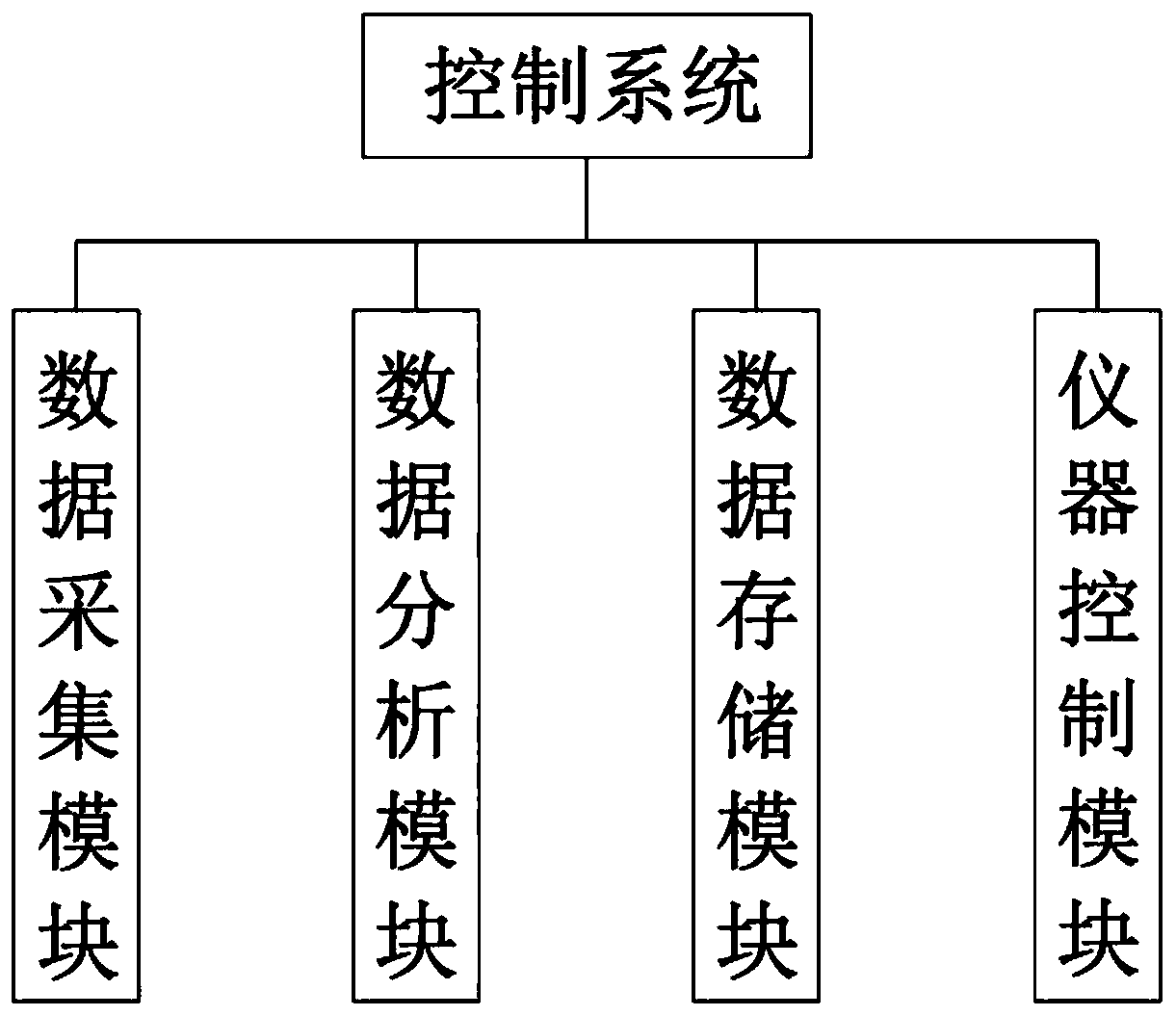

[0029] Such as figure 1 As shown, a circulator and isolator automatic debugging device includes a workbench 9 on which a magnetizer 5 and a vector network analyzer 8 are arranged, and a magnetizer box 4 is arranged in front of the magnetizer 5 , the vector network analyzer 8 is connected with a test fixture 6, and a mechanical arm 3 is installed on the outside of the workbench 9. The mechanical arm 3 has three degrees of freedom, and its grasping range covers the test fixture 6 and magnetization. The box 4, the manipulator 3, the magnetizer 5 and the vector network analyzer 8 are connected to a control system 7, and the control system 7 includes a data acquisition module, a data analysis module and an instrument control module.

[0030] Preferably, a magnetization area 41 and a demagnetizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com