Phosphogypsum decomposition process

A phosphogypsum, calcium sulfate technology, applied in chemical instruments and methods, inorganic chemistry, calcium/strontium/barium oxide/hydroxide, etc., can solve problems such as economic infeasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

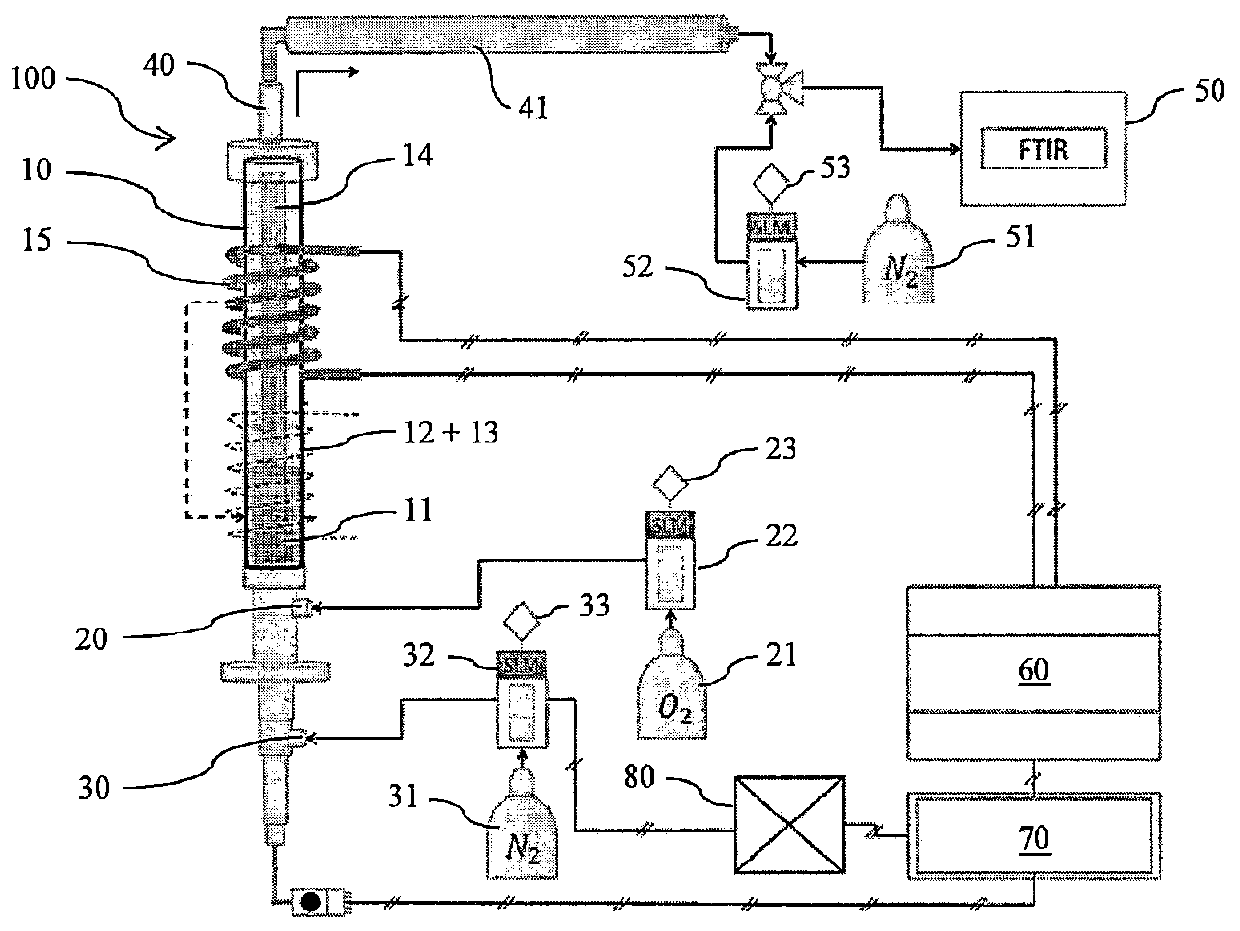

Method used

Image

Examples

Embodiment 1

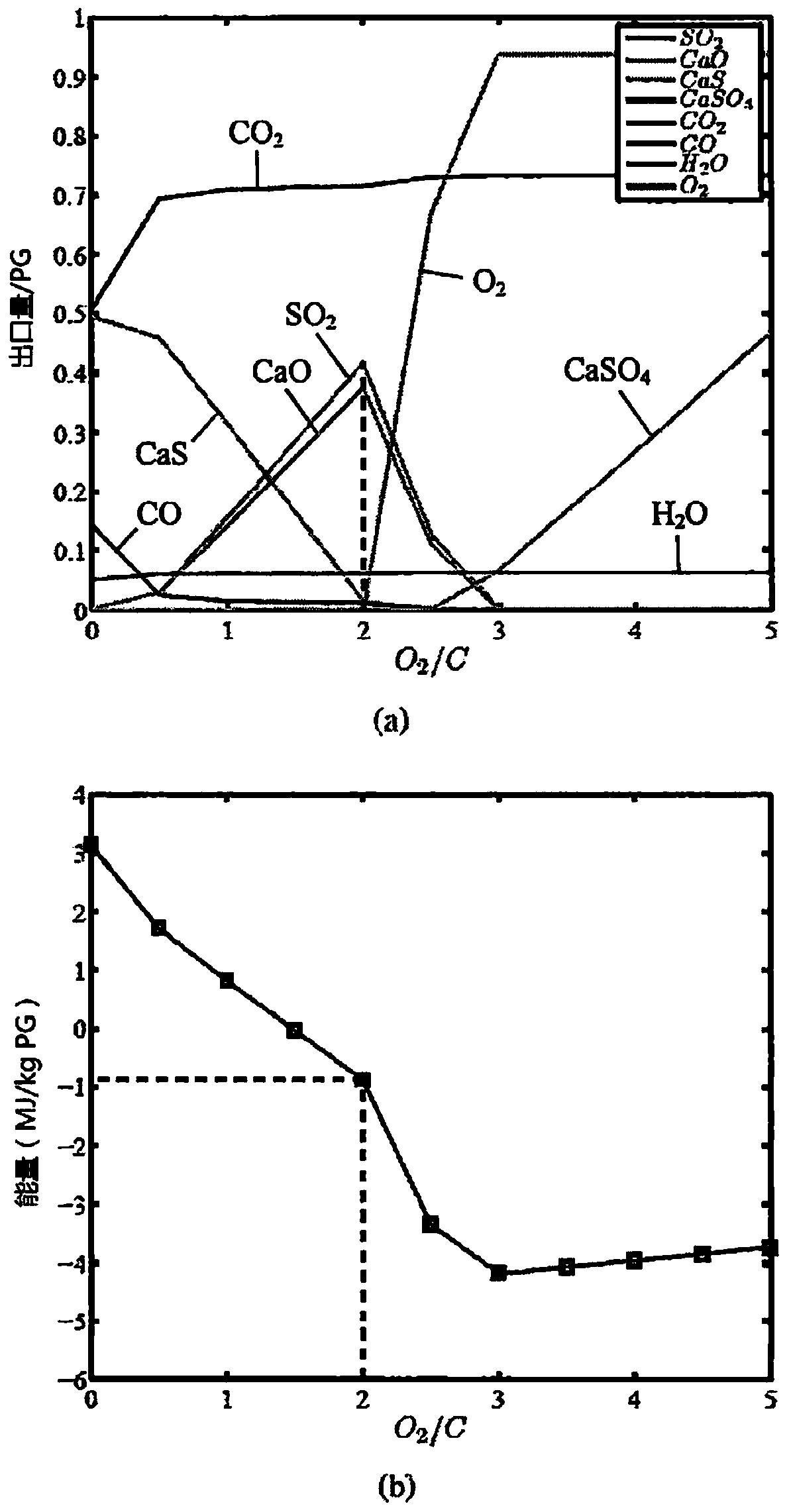

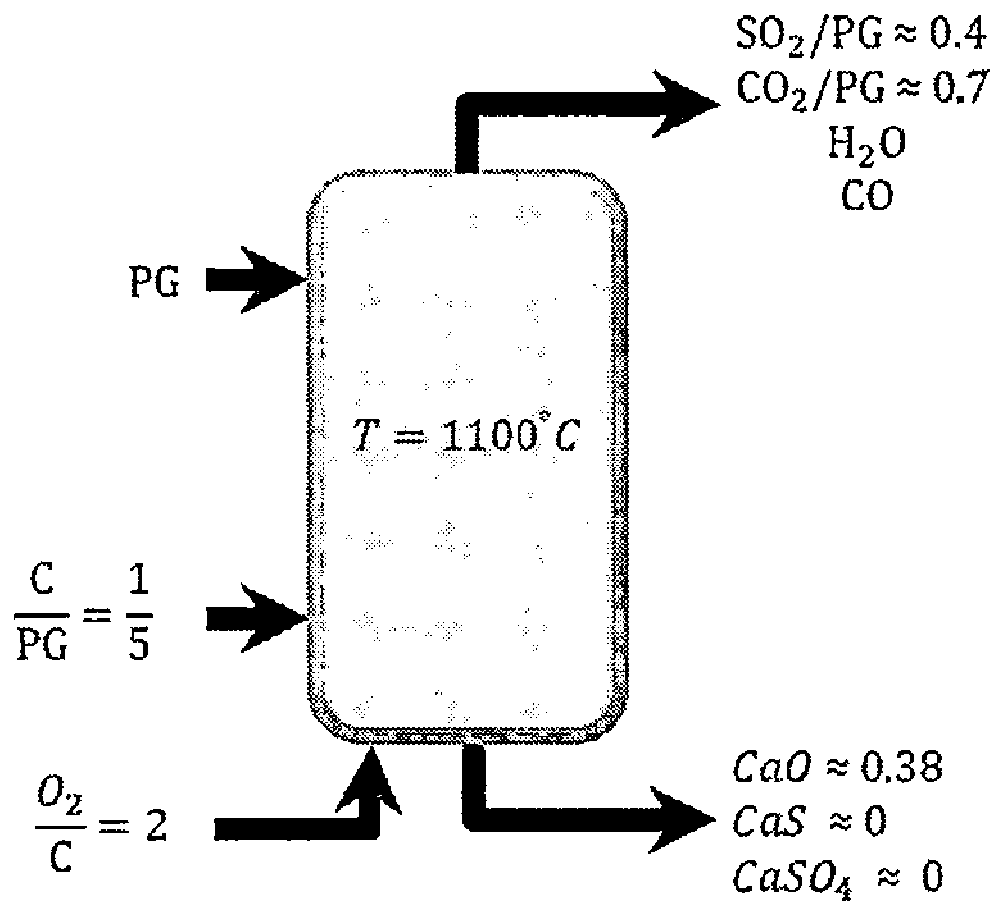

[0071] Example 1 - Decomposition of PG into SO 2 and CaO for optimal carbon and O 2

[0072] Carbon oxidation provides the CO required to react with PG at 1100 °C according to the following reaction:

[0073] CaSO 4 +CO→CaO+SO 2 +CO 2 T=1100°C (3)

[0074] However, the following undesired reactions also occur at 1100 °C, which indicates an optimal demand for CO concentration:

[0075] CaSO 4 +4CO→CaS+CO 2 T=1100°C (4)

[0076] Decomposing phosphogypsum under CO has the significant benefit of reducing the operating temperature from 1560°C to 1100°C, thereby reducing the energy expended to maintain the reactor at this temperature.

[0077] However, maintaining the reactor at 1100°C also requires a large amount of energy, making the method economically impractical.

[0078] Typically, CO can be produced from different sources such as steam reforming (natural gas) or coal / biomass oxidation. In the case of coal / biomass oxidation, by adding O 2 CO, CO 2 and H 2 O,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com