Preparation process for hydrolyzed jojoba ester semi-transparent system and application of preparation process

A preparation process, translucent technology, applied in the direction of skin care preparations, cosmetic preparations, dressing preparations, etc., can solve the problems of skin irritation and inconvenient operation, so as to reduce skin irritation and reduce energy consumption. The effect of less and stronger water retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

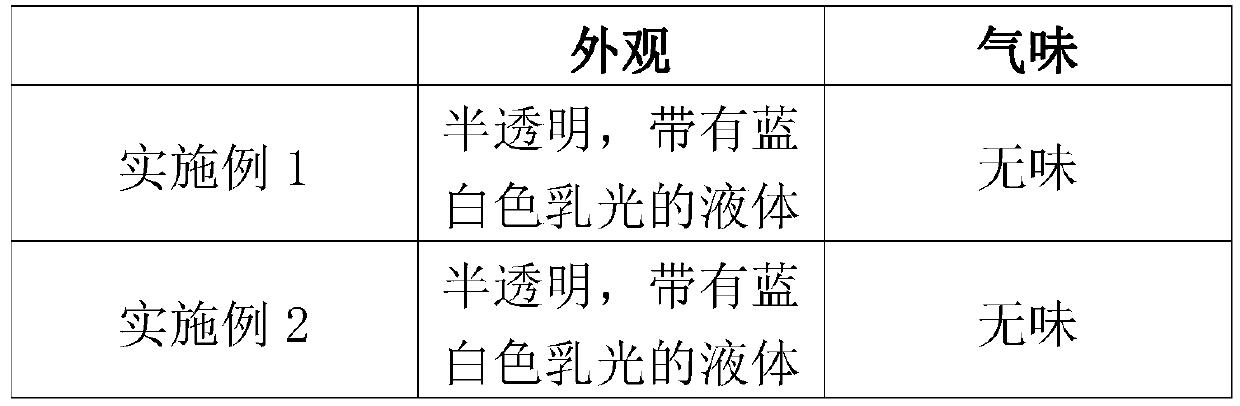

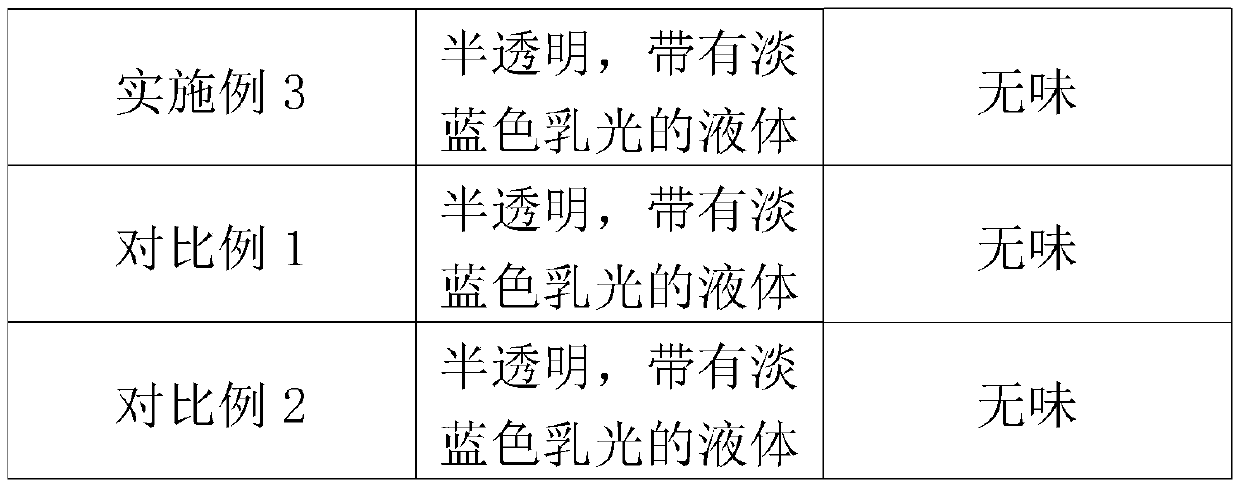

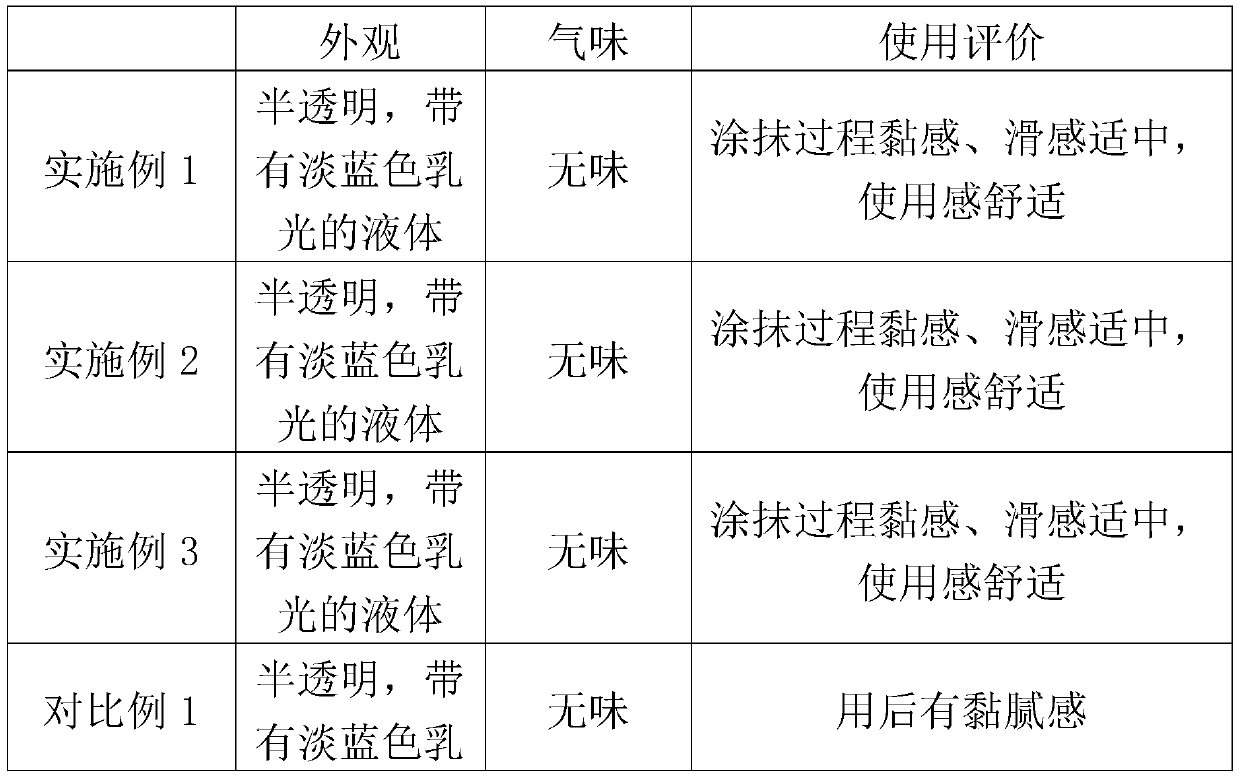

Examples

Embodiment 1

[0021] S1. Add 1 g of hydrolyzed jojoba esters to 2 g of glycerin, and stir for 15 min with a stirrer at a speed of 15 rpm;

[0022] S2. Add 2g of methylpropanediol to the mixed solution prepared in step S1, and stir for 15min at a speed of 15 rpm;

[0023] S3. Heat the mixed solution to 45°C, add 10g of 45°C purified water at a speed of 15 rpm, stir for 15min, cool down to 20°C, and keep warm for 10h to obtain the jojoba ester translucent system.

Embodiment 2

[0025] S1. Add 0.8 g of hydrolyzed jojoba esters to 1.6 g of glycerin, and stir for 5 min with a stirrer at a speed of 15 rpm;

[0026] S2. Add 1.6 g of methylpropanediol to the mixed solution prepared in step S1, and stir for 5 min at a speed of 15 rpm;

[0027] S3. Heat the mixed solution to 37°C, add 30g of 37°C pure water at 15 rpm, stir for 25min, cool down to 15°C, and keep warm for 8h to obtain a translucent jojoba ester system.

Embodiment 3

[0029] S1. Add 1.2 g of hydrolyzed jojoba esters to 2.4 g of glycerin, and stir for 25 min with a stirrer at a speed of 15 rpm;

[0030] S2. Add 2.4g methylpropanediol to the mixed solution prepared in step S1, and stir for 25min at a speed of 15 rpm;

[0031] S3. Heating the mixed solution to 50°C, adding 60g of 50°C purified water at a speed of 15 rpm, stirring for 5min, cooling to 30°C, and keeping it warm for 12h to obtain the jojoba ester translucent system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com