Green and energy-saving fire-extinguishing device for thermal insulation layer of building external wall

A technology for building exterior walls and fire extinguishing devices, which is applied in fire rescue and other fields, and can solve problems such as potential safety hazards and unsatisfactory fire prevention effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

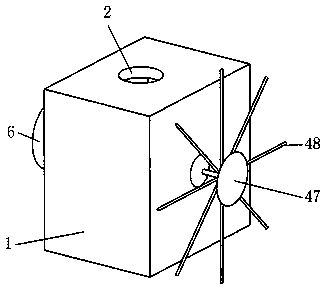

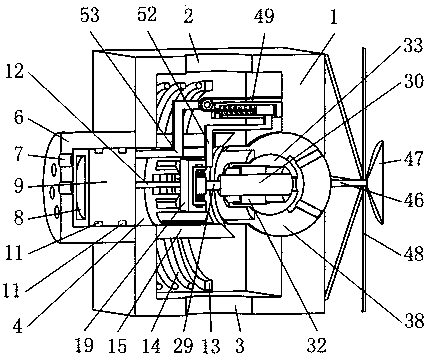

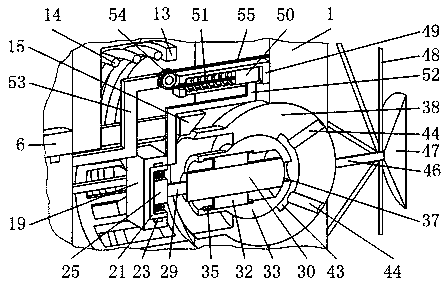

[0033] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

[0034] Such as figure 1 , 2 , 3, it includes shell 1, cylinder A6, glass body 8, slide plug 9, spring A14, cylinder B15, guide seat A19, guide seat B21, spring B24, slider A25, spring C27, connecting rod A29 , blocking post 30, overcoat A33, overcoat B38, driving lever 46, cone 47, guide seat C49, slide block B50, spring D51, fixed pulley 54, wire rope B55 made up of sphere 39 and cylinder 59, wherein as figure 2 , 5 As shown, the transmission hole 4 on the two side walls of the casing 1 is opposite to the spherical hole 5, and a cylinder A6 with an open end is installed at the transmission hole 4 outside the casing 1; figure 2 , 4 As shown, there is a sliding plug 9 in axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com