A load control system and method for a cement ball mill

A load control, cement ball technology, applied in grain processing and other directions, can solve the problems of noise amplification effect, larger error, large initial control force, etc., and achieve the effect of solving error amplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

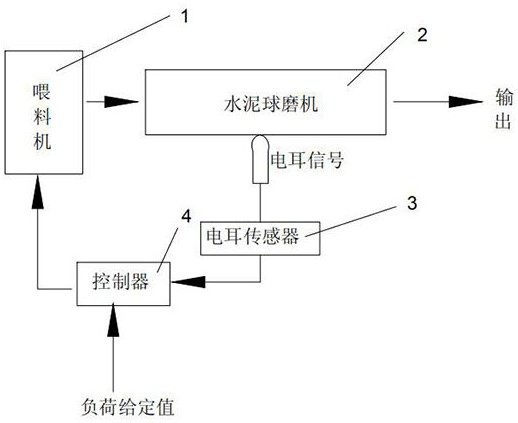

[0043] Such as figure 1 As shown, the load control system of a cement ball mill provided in this embodiment includes the following components:

[0044] A feeder 1 capable of conveying materials;

[0045] Cement ball mill 2 for grinding the material delivered by feeder 1;

[0046] An electric ear sensor 3 located outside the cement ball mill 2 and used to detect the material filling rate in the cement ball mill 2;

[0047] Electrically connected with the electric ear sensor 3, and pre-stored with a controller 4 with a given range of load;

[0048] Wherein the controller 4 is also electrically connected with the feeder 1, and after obtaining the real-time load signal of the electric ear sensor 3 in real time, it is compared with the preset load given range to optimize the environmental impact of the cement ball mill during work. The problem of the influence of the feeding amount of the feeder 1, and finally obtain a suitable feeding amount, so as to realize the process of aut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com