Surface wave time-frequency regulated localized heterogeneous composite material preparation device and method

A composite material and a technology for preparing devices, which can be used in devices for coating liquids on surfaces, pretreatment surfaces, coatings, etc., can solve problems such as poor regional selectivity, and achieve the effect of enhancing diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

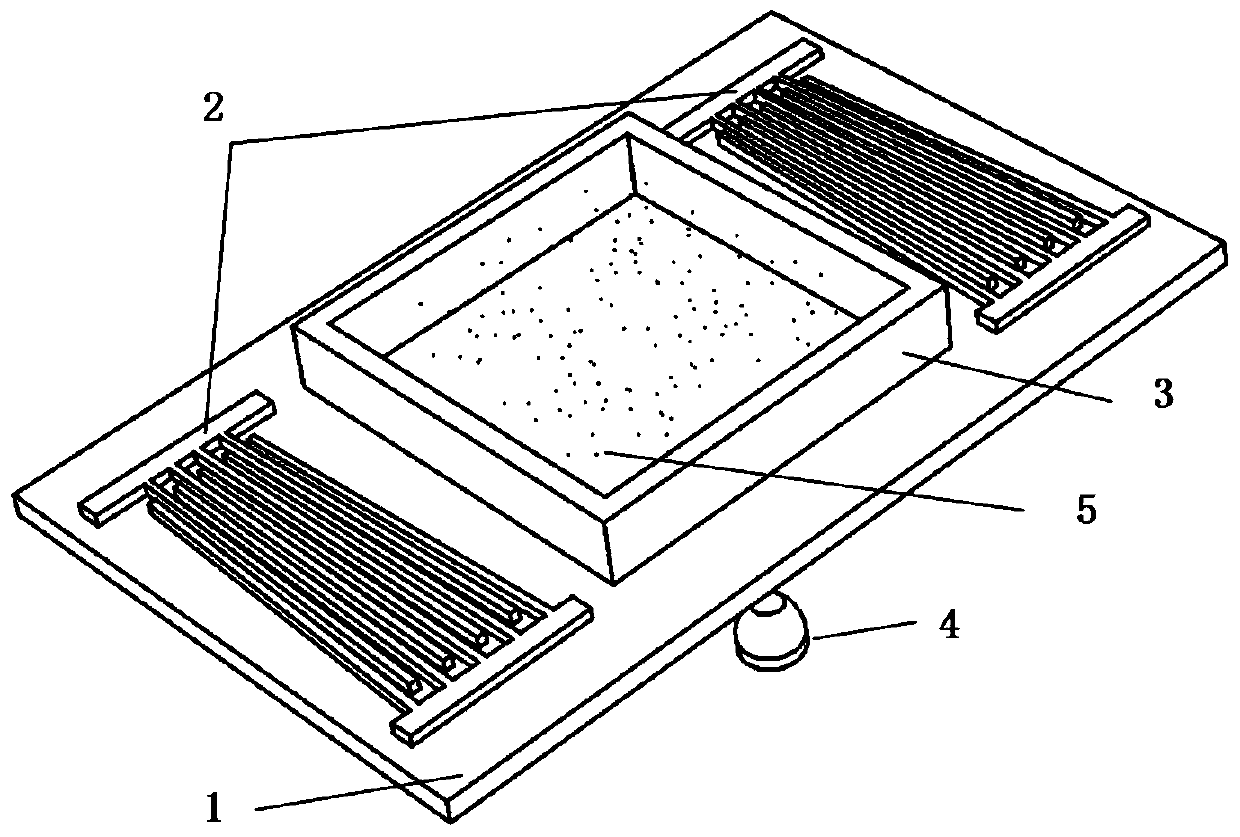

[0031] In order to realize the preparation of localized heterogeneous composite materials, a pair of frequency-variable surface acoustic wave transducers 2 can be slanted fingers or arc fingers. If a pair of frequency-variable surface acoustic wave transducers 2 are oblique fingers, such as figure 1 As shown, a pair of frequency-variable interdigital transducers should be symmetrically distributed on the lithium niobate wafer 1 . If the pair of frequency-variable surface acoustic wave transducers 2 are arc fingers, the centers of the curvature radii of the pair of frequency-variable interdigital transducers 2 should coincide with one point and be symmetrically distributed with respect to the center of this point. The above structural design can ensure that a pair of frequency-variable surface acoustic wave transducers 2 are excited to generate surface acoustic waves of different frequencies, which can be superimposed in the central area of a pair of frequency-variable surfac...

example 1

[0039] Example 1: Distribution range characteristics of surface acoustic standing waves based on frequency regulation of surface acoustic waves

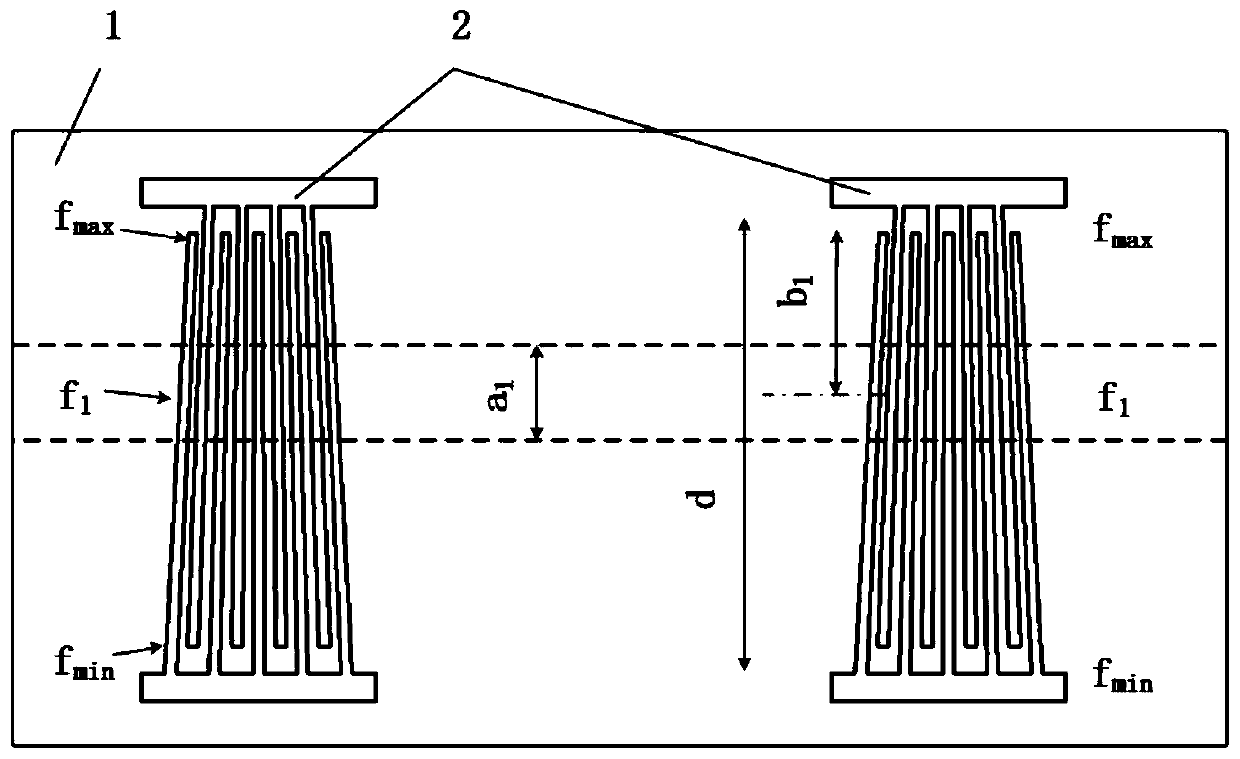

[0040] Such as figure 2 Shown is a pair of oblique-fingered frequency-variable surface acoustic wave transducers, which can be regarded as figure 1 The top view of the device without the liquid tank 3 and the mixture 5. According to the principle of the surface acoustic wave transducer, the excitation frequency of the transducer corresponds to the finger width, which is f=c / 4m, and c is the sound velocity of the lithium niobate wafer 1 parallel to the finger width direction of the variable frequency surface acoustic wave transducer 2, m is the finger width (or finger spacing) of a pair of oblique finger variable frequency SAW transducers. Since the finger width of the variable frequency SAW transducer varies, the adjustment range of the excitation frequency is f min max , the minimum frequency f min Corresponding to the point wit...

example 2

[0044] Example 2: Distribution range characteristics of surface acoustic standing waves based on time regulation of surface acoustic waves

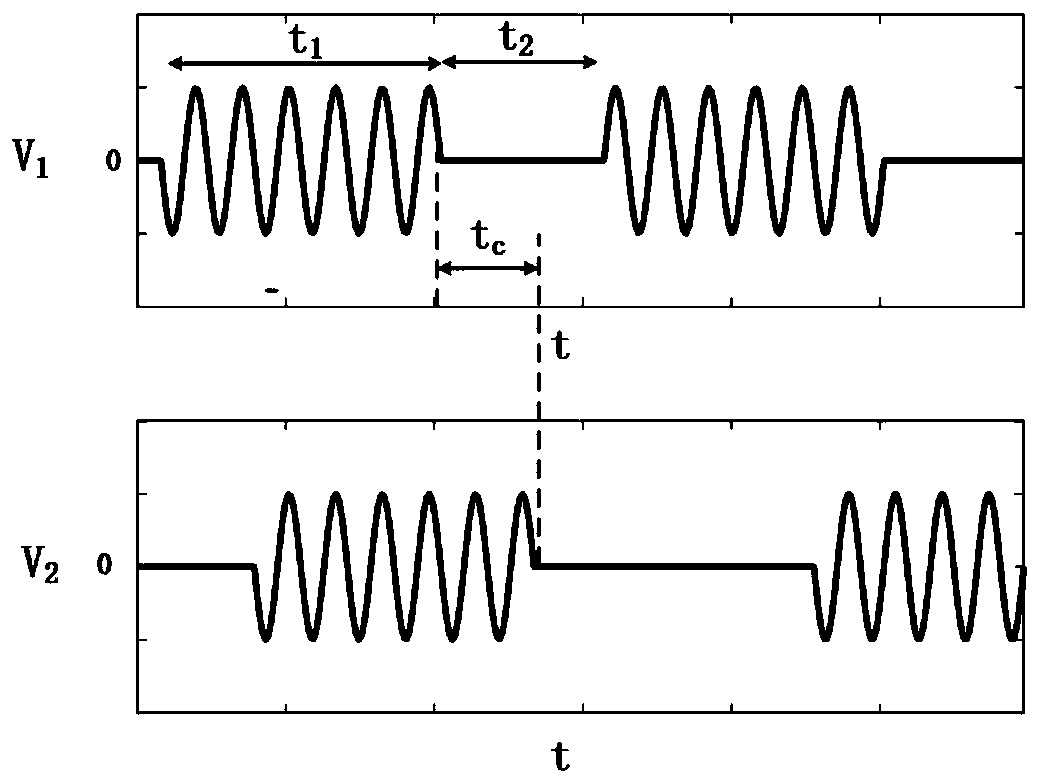

[0045] For convenience, the two-dimensional case is analyzed, namely figure 2 The surface wave propagation characteristics of the time-regulated sinusoidal signal input to the frequency-variable surface acoustic wave transducer 2 along the horizontal midline section. A time-regulated input signal such as image 3 As shown, V 1 with V 2 are the input signals of a pair of surface acoustic wave transducers, respectively. where t 1 It is a sinusoidal signal in time and zero input signal input in time t2, V 1 with V 2 The signal is exactly the same in each cycle but there is a relative time difference t c . The period of the sinusoidal signal should correspond to the excitation frequency of the frequency-variable surface acoustic wave transducer 2 at a specific position. let t m is the time taken for the surface acoustic wave to pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com