Roll coating process for PU paint

A processing technology, roller coating technology, applied in coating, device for coating liquid on surface, surface pretreatment, etc., can solve problems such as unfavorable staff health, lack of test confirmation, coloring error, etc., to avoid fogging The effect of paint droplets, avoiding chromatic aberration, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

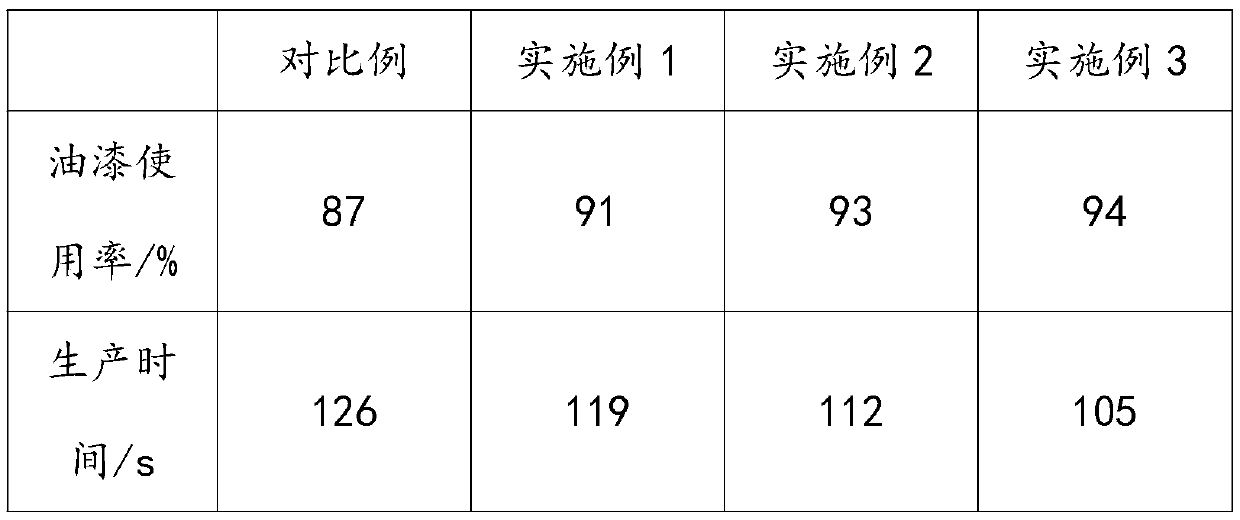

Examples

Embodiment 1

[0030] Step 1: Inspection and basic chamfering of the base plate: conduct a comprehensive inspection of the outer surface of the base plate, completely remove the unqualified base plate with bulges, depressions, cracks, and deformations on the surface, and check the surface of the qualified base plate Carry out cleaning, after the cleaning is finished, after the base plate is dry, fillet the reverse side of the base plate, fillet the two long sides of the front side, and chamfer the short side;

[0031] Step 2: Sanding treatment of the base plate: place the base plate horizontally on the surface of the operation platform, after fixing the base plate, use a sander to perform a comprehensive sanding operation on the surface of the base plate, and use The inspection equipment inspects the product one by one, and removes the surface dirt generated during sanding;

[0032] Step 3: Roller coating the first color paint: use a double-roller coloring roller coater, the first roller is ...

Embodiment 2

[0038] Step 1: Inspection and basic chamfering of the base plate: conduct a comprehensive inspection of the outer surface of the base plate, completely remove the unqualified base plate with bulges, depressions, cracks, and deformations on the surface, and check the surface of the qualified base plate After cleaning, after the substrate board is dry, fillet the reverse side of the substrate board, round the two long sides of the front side, and chamfer the short side;

[0039] Step 2: Sanding treatment of the base plate: place the base plate horizontally on the surface of the operation platform, after fixing the base plate, use a sander to perform a comprehensive sanding operation on the surface of the base plate, and use The inspection equipment inspects the product one by one, and removes the surface dirt generated during sanding;

[0040]Step 3: Roller coating the first color paint: use a double-roller coloring roller coater, the first roller is a sponge roller, the second ...

Embodiment 3

[0046] Step 1: Inspection and basic chamfering of the base plate: conduct a comprehensive inspection of the outer surface of the base plate, completely remove the unqualified base plate with bulges, depressions, cracks, and deformations on the surface, and check the surface of the qualified base plate Carry out cleaning, after the cleaning is finished, after the base plate is dry, fillet the reverse side of the base plate, fillet the two long sides of the front side, and chamfer the short side;

[0047] Step 2: Sanding treatment of the base plate: place the base plate horizontally on the surface of the operation platform, after fixing the base plate, use a sander to perform a comprehensive sanding operation on the surface of the base plate, and use The inspection equipment inspects the product one by one, and removes the surface dirt generated during sanding;

[0048] Step 3: Roller coating the first color paint: use a double-roller coloring roller coater, the first roller is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com