A full hydraulic fruit and vegetable processing equipment

A processing equipment and full hydraulic technology, applied in grain processing, presses, chemical/physical processes, etc., can solve the problems of large heat loss, high energy consumption of the device, incomplete mixing, etc., to achieve increased energy consumption and precise control Systematic, efficient and thorough mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is further illustrated by the following examples.

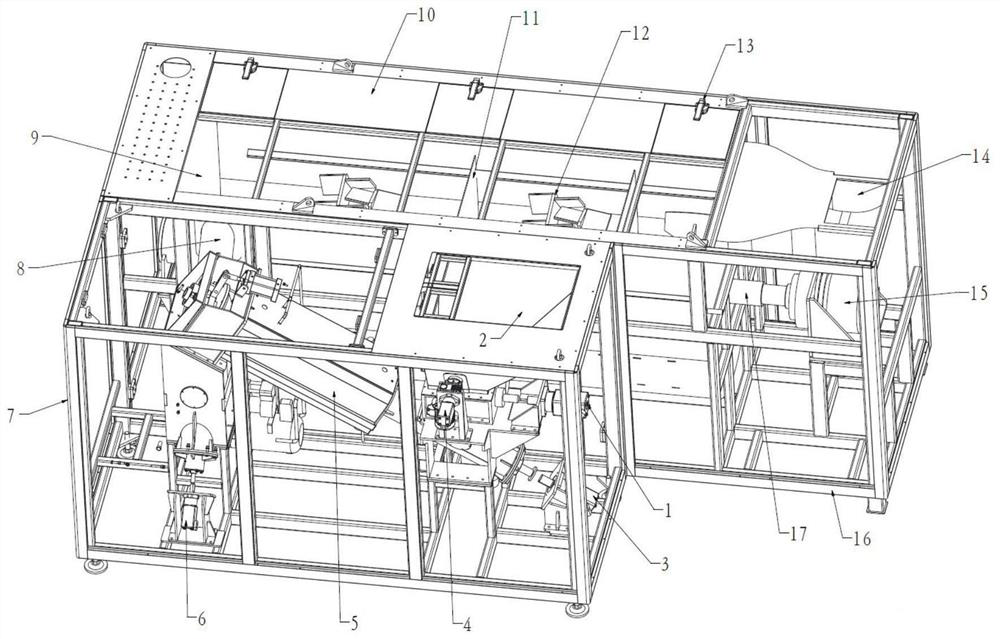

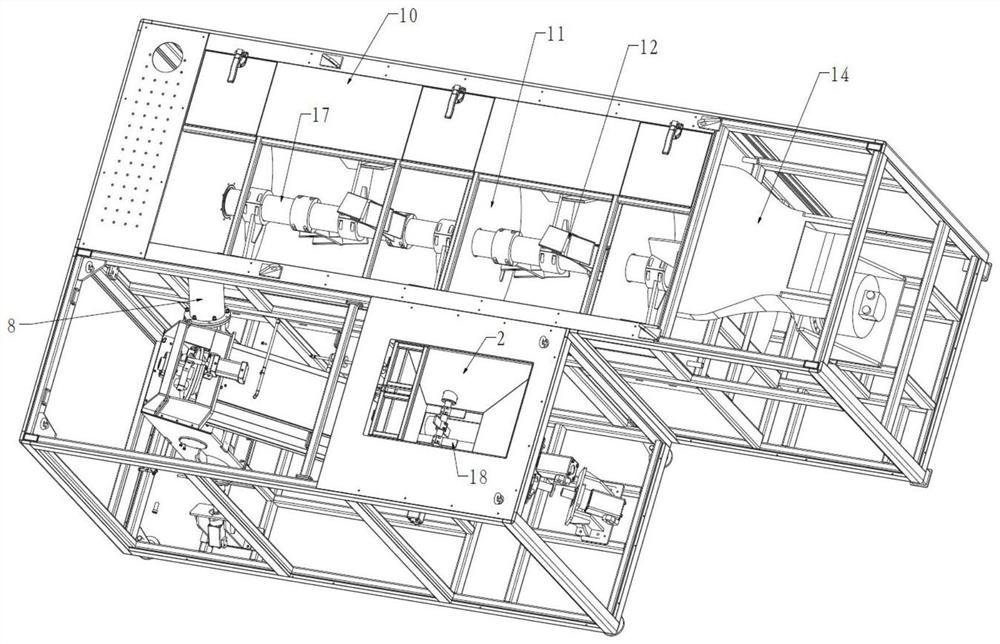

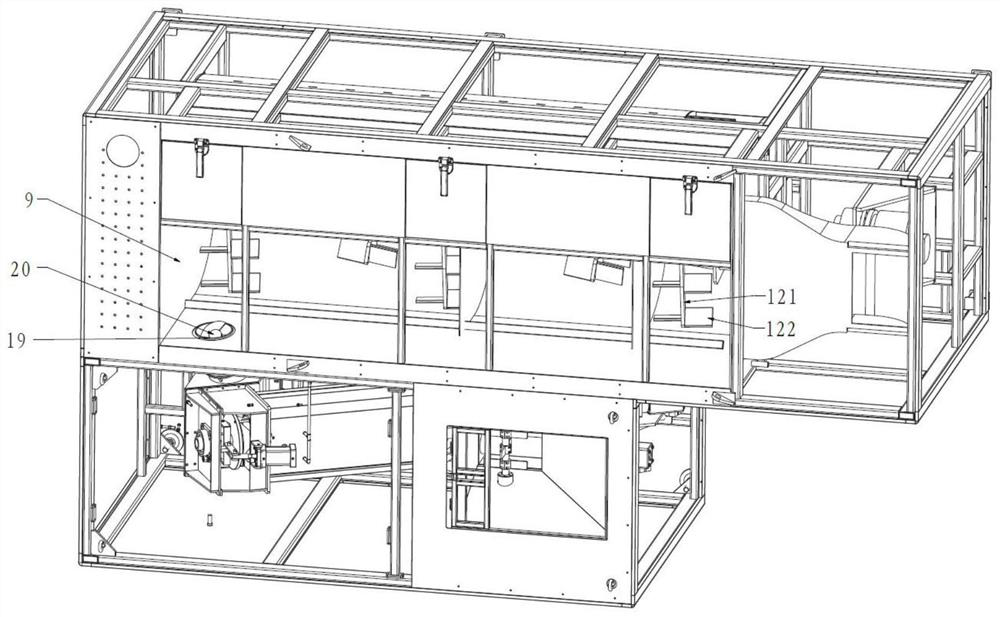

[0031]A fully hydraulic fruit and vegetable processing equipment, including a pretreatment part and a stirring fermentation part, the pretreatment part includes a first support frame 7, a hopper-shaped discharge port 2 is arranged on the first support frame 7, and a There is a blanking stirring device 18, the blanking stirring device 18 is driven by the blanking stirring hydraulic motor 4, and a crushing device is also arranged under the blanking stirring device 18 in the blanking port 2, and the crushing device is driven by the crushing device hydraulic motor 1 Drive; the feeding port 2 is connected with a squeezing device 5, and the squeezing device 5 includes a squeeze feeding pipeline arranged obliquely, and a squeezing shaft 24 is arranged in the pipeline, and the squeezing shaft 24 is driven by the hydraulic motor 3 of the squeezing device, and the squeezing shaft 24 Squeezing blades 25 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com