Novel hot die forging press

A hot die forging press, a new type of technology, applied in the driving device of the forging press, the forging/pressing/hammering machinery, the forging/pressing/hammer device, etc. It can improve the stability and safety, improve the accuracy and reliability, and enhance the clutch effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

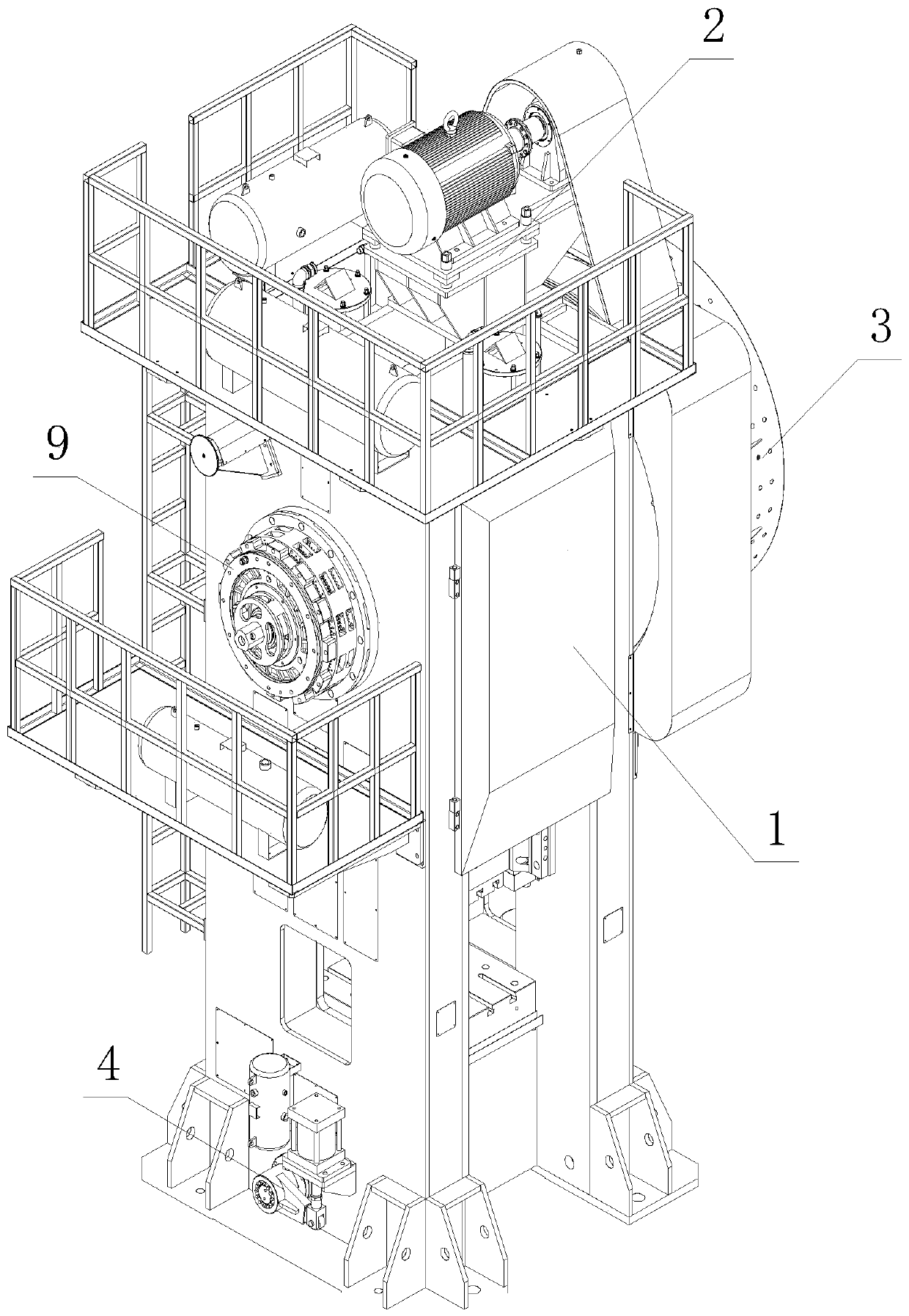

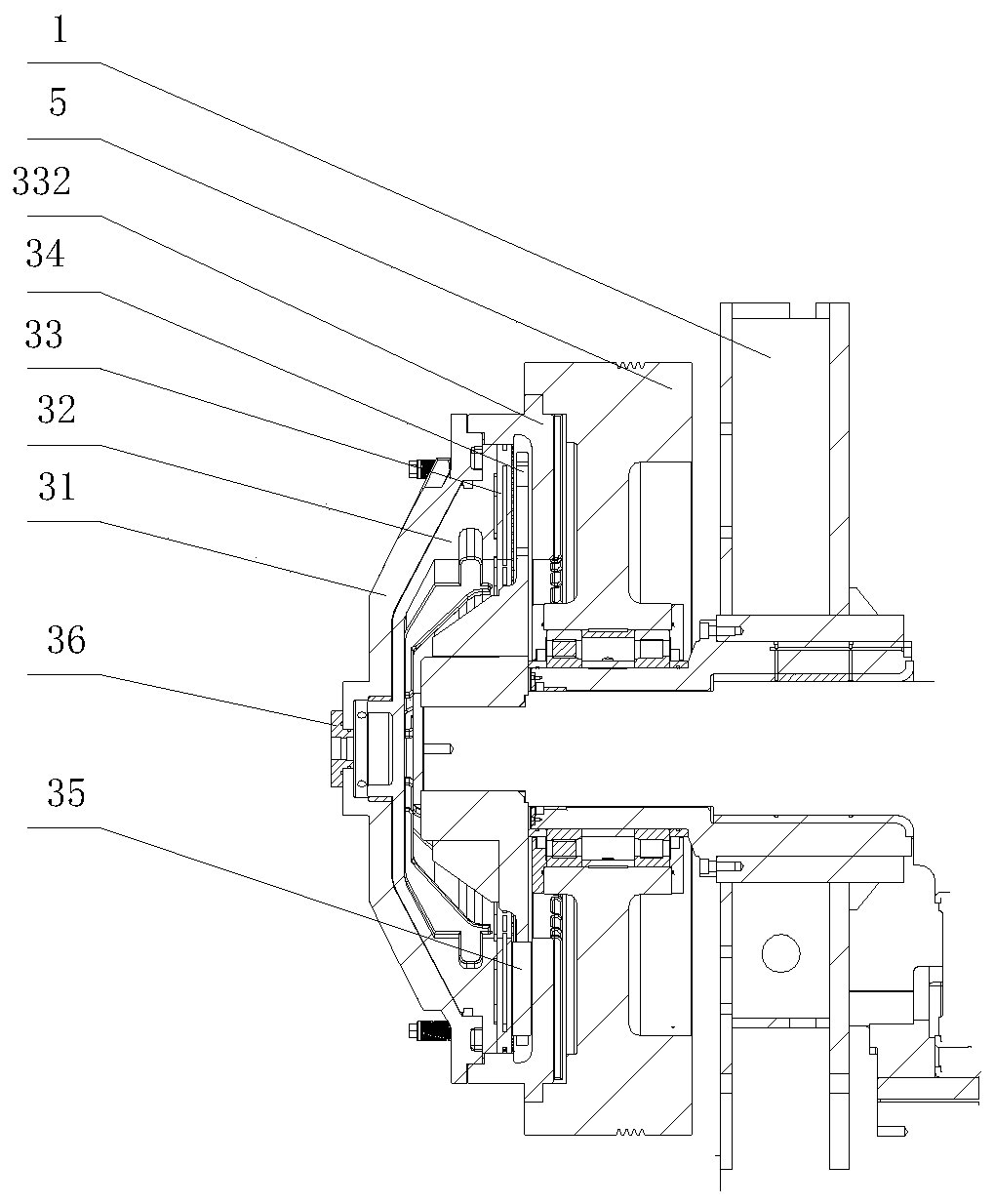

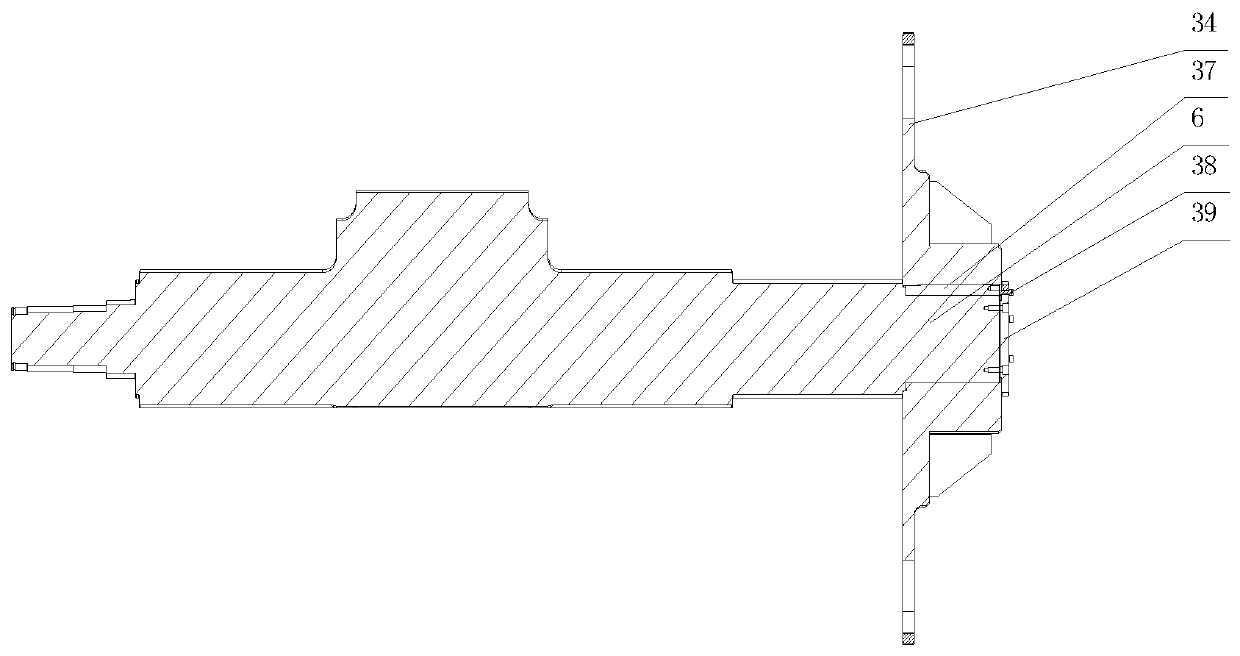

[0028] refer to Figure 1 to Figure 10, the present invention comprises a frame 1 and a main motor mechanism 2, a clutch mechanism 3, an upper material jacking mechanism and a lower material jacking mechanism 4 arranged on the frame 1, and the main motor mechanism 2 is driven and connected with a flywheel 5 through a transmission belt, so that Described flywheel 5 is connected with crankshaft 6 through clutch mechanism 3, and described crankshaft 6 is connected with connecting rod 7, and described connecting rod 7 is connected with slide block 8, and described crankshaft 6 is rotated and can make described slide block by the transmission of connecting rod 7. 8 moves up and down, the slider 8 is connected with the feeding and ejecting mechanism, the frame 1 is provided with a mold height adjustment mechanism that drives the slider 8 to rise and fall relative to the connecting rod 7, the flywheel 5 and the clutch mechanism 3 Installed on one end of the crankshaft 6, the other en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com