A guide vane mold and its shrinkage design method

A technology of guide vane and mold shrinkage, which is applied in the field of precision casting, can solve the problems of extended delivery period, blade throat area out of tolerance, and inability to open the mold, so as to promote engineering application, improve design technology, and solve mold opening interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A slender five-joint equiaxed crystal turbine guide vane of an engine blade:

[0054] Step 1, set parameters

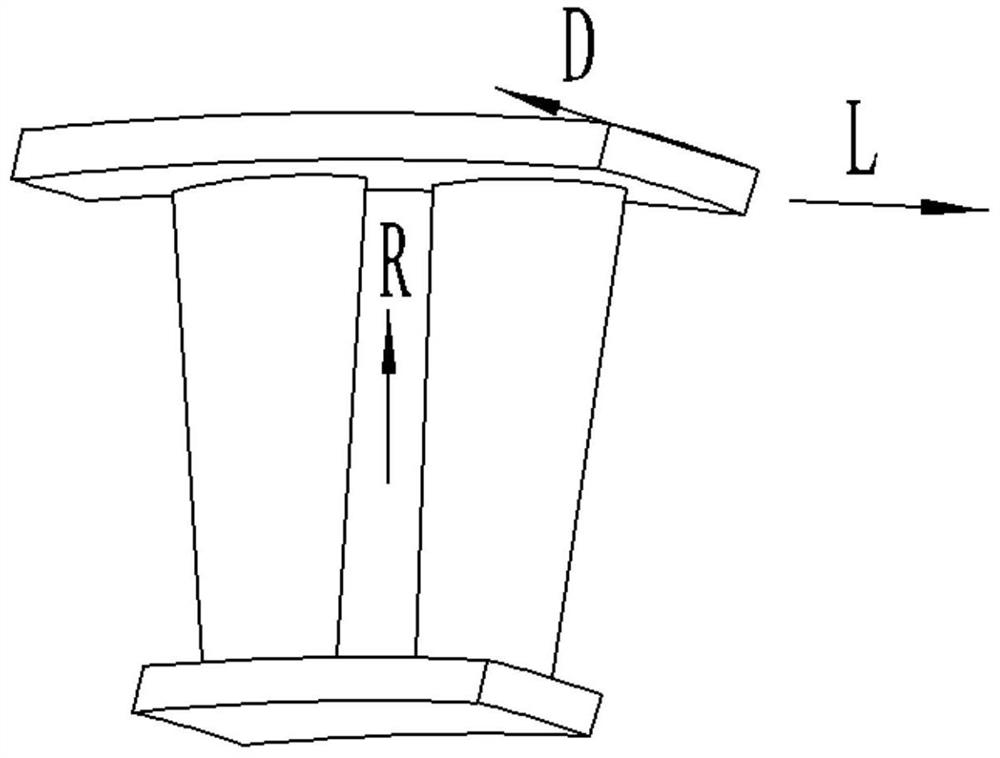

[0055] The length of the blade body is A=225mm; the length direction of the blade is the R direction, which coincides with the coordinate axis Z axis, and the shrinkage rate is ψ1=2.4%;

[0056] The chord length direction of the upper and lower edge plates is the L direction, which coincides with the X axis of the coordinate axis, and the shrinkage rate is ψ2=1.8%;

[0057] The width direction of the upper and lower edge plates is the D direction, which coincides with the coordinate axis Y axis, and the shrinkage rate is ψ3=1.8%.

[0058] Step 2, mold shrinkage setting method

[0059] Taking the origin of the blade engine as the center of the circle, the blade is enlarged as a whole according to the shrinkage rate of 1.8%. The shrinkage rate given in the direction of the blade body is 0.6% smaller than the actual shrinkage rate, and the length of the blade bo...

Embodiment 2

[0062] A single-connected equiaxed crystal turbine guide vane with short blade body and large edge plate in an engine:

[0063] Step 1, set parameters

[0064] The blade body length is A=110mm;

[0065] The length direction of the blade is the R direction, which coincides with the coordinate axis Z axis, and the shrinkage rate is ψ1=1.8%;

[0066] The chord length direction of the upper and lower edge plates is the L direction, which coincides with the X axis of the coordinate axis, and the shrinkage rate is ψ2=2.2%;

[0067] The width direction of the upper and lower edge plates is the D direction, which coincides with the coordinate axis Y axis, and the shrinkage rate is ψ3=2.2%.

[0068] Step 2, mold shrinkage setting method

[0069] Taking the origin of the blade engine as the center of the circle, the blade is enlarged as a whole according to the shrinkage rate of 2.2%. The shrinkage rate given in the direction of the blade body is 0.4% larger than the actual shrinkage...

Embodiment 3

[0071] A single directionally solidified turbine guide vane with the same size as the airfoil and edge plate of an engine:

[0072] Step 1, given parameters

[0073] The blade body length is A=180mm;

[0074] The length direction of the blade is the R direction, which coincides with the coordinate axis Z axis, and the shrinkage rate is ψ1=1.6%;

[0075] The chord length direction of the upper and lower edge plates is the L direction, which coincides with the X axis of the coordinate axis, and the shrinkage rate is ψ2=2.1%;

[0076] The width direction of the upper and lower edge plates is the D direction, which coincides with the coordinate axis Y axis, and the shrinkage rate is ψ3=2.1%.

[0077] Step 2, mold shrinkage setting method

[0078] Taking the origin of the blade engine as the center of the circle, the blade is enlarged as a whole according to the shrinkage rate of 2.1%. The shrinkage rate given in the direction of the blade body is 0.5% larger than the actual shr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com