Hydraulic processing method of glass fiber reinforced plastic product

A technology of hydraulic processing and glass fiber reinforced plastics, which is applied in the direction of manufacturing tools, presses, stamping machines, etc., can solve the problems of fast no-load speed, single downward speed of the slider, and slow heavy-load speed, so as to improve the pressing efficiency and improve the work efficiency. The effect of speed and long travel distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

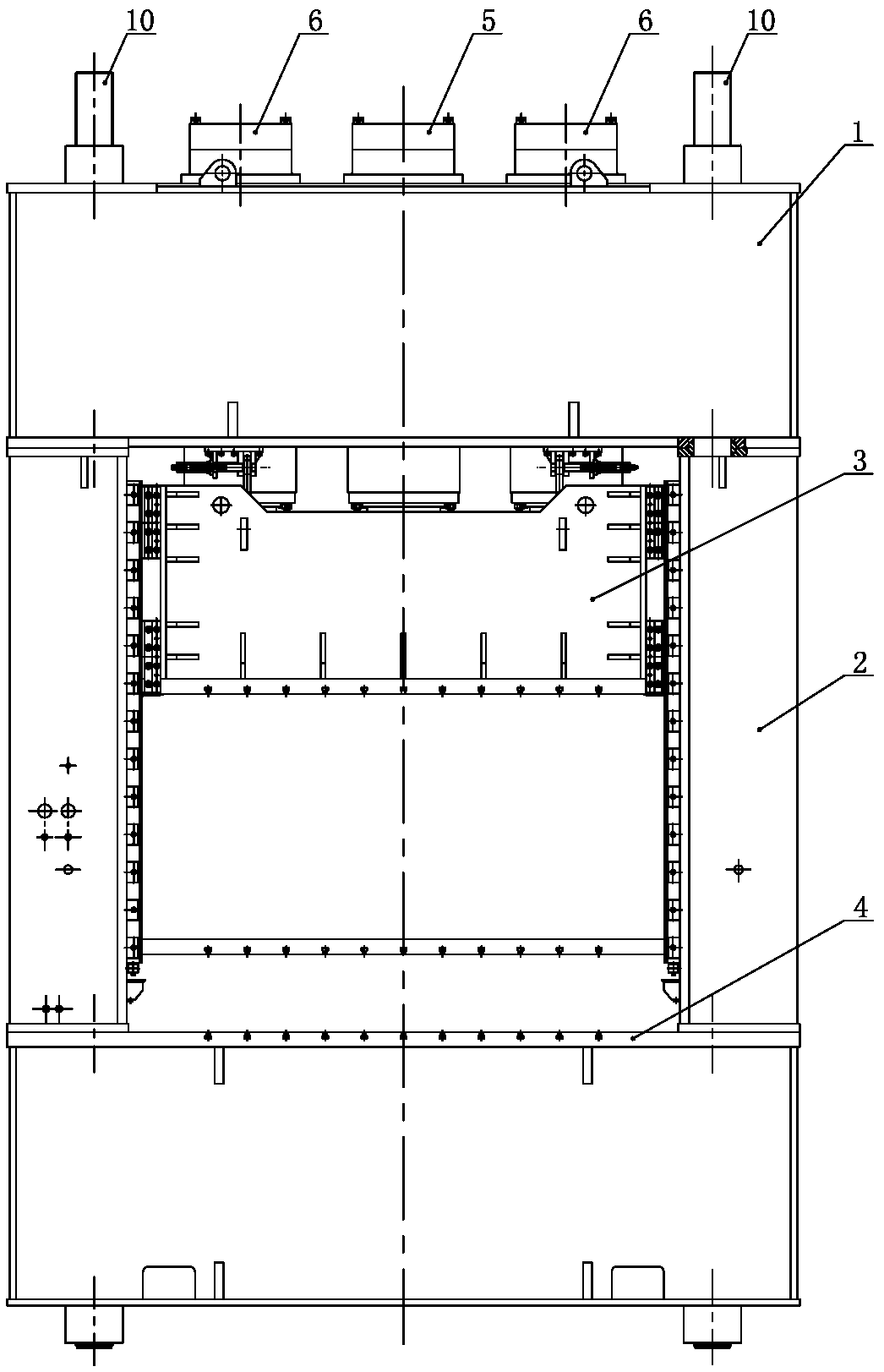

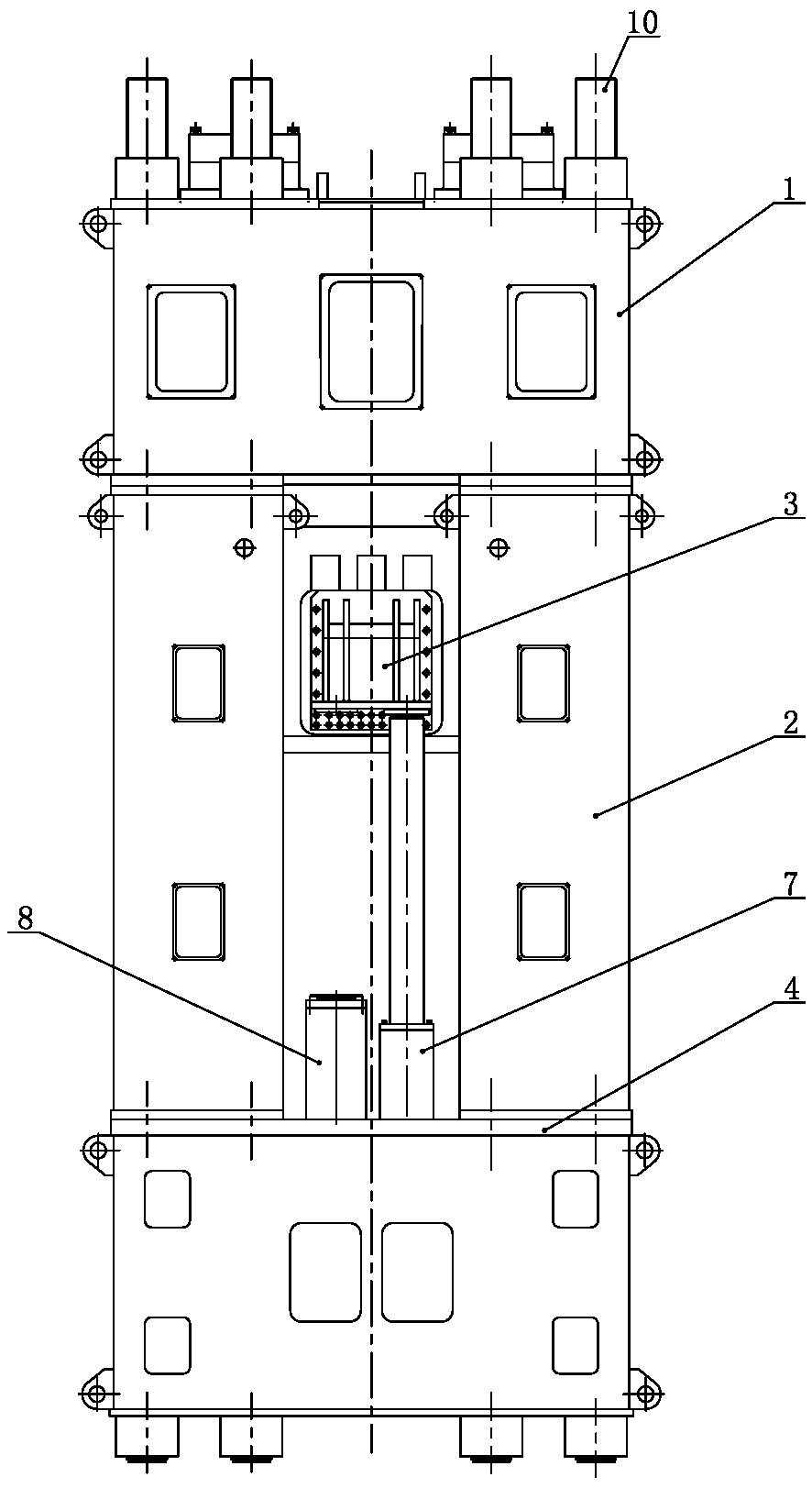

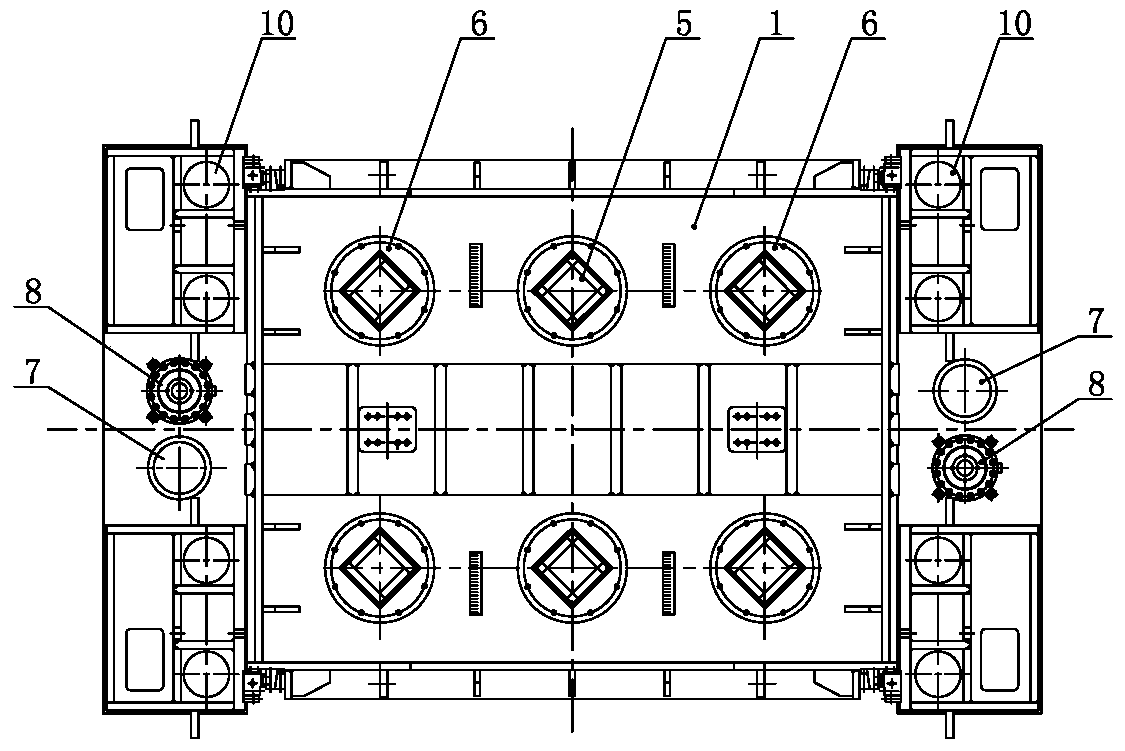

[0022] Such as Figure 1 to Figure 4 As shown, the hydraulic press used in the present invention includes a workbench 4, four corners of the workbench 4 are installed with uprights 2, the tops of the two rows of uprights are connected to each other by the upper crossbeam 1 extending in the left and right direction, each of the uprights Tie rods 10 are inserted into the front and the rear, respectively. The upper ends of the tie rods 10 respectively penetrate from the top of the upper beam 1 and are fixed to the upper beam 1 by upper nuts. The lower ends of the tie rods 10 respectively penetrate the bottom of the workbench 4 And fixed on the workbench through the lower nut; the middle part of the upper beam 1 is respectively installed with the middle cylinder 5, the left and right sides of the middle cylinder 5 are respectively installed with side cylinders 6 symmetrically, each of the middle cylinder 5 and the lower end of the plunger of the side cylinder 6 Both are fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com