Lifting device for wall cupboard

A technology of lifting device and hanging cabinet, applied in the direction of lifting device, lifting frame, hoisting device, etc., can solve the problems of low space utilization rate, reducing self-locking force of transmission mechanism, complicated structure of hanging cabinet body, etc., and saving replacement time. and cost, the effect of improving the replacement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

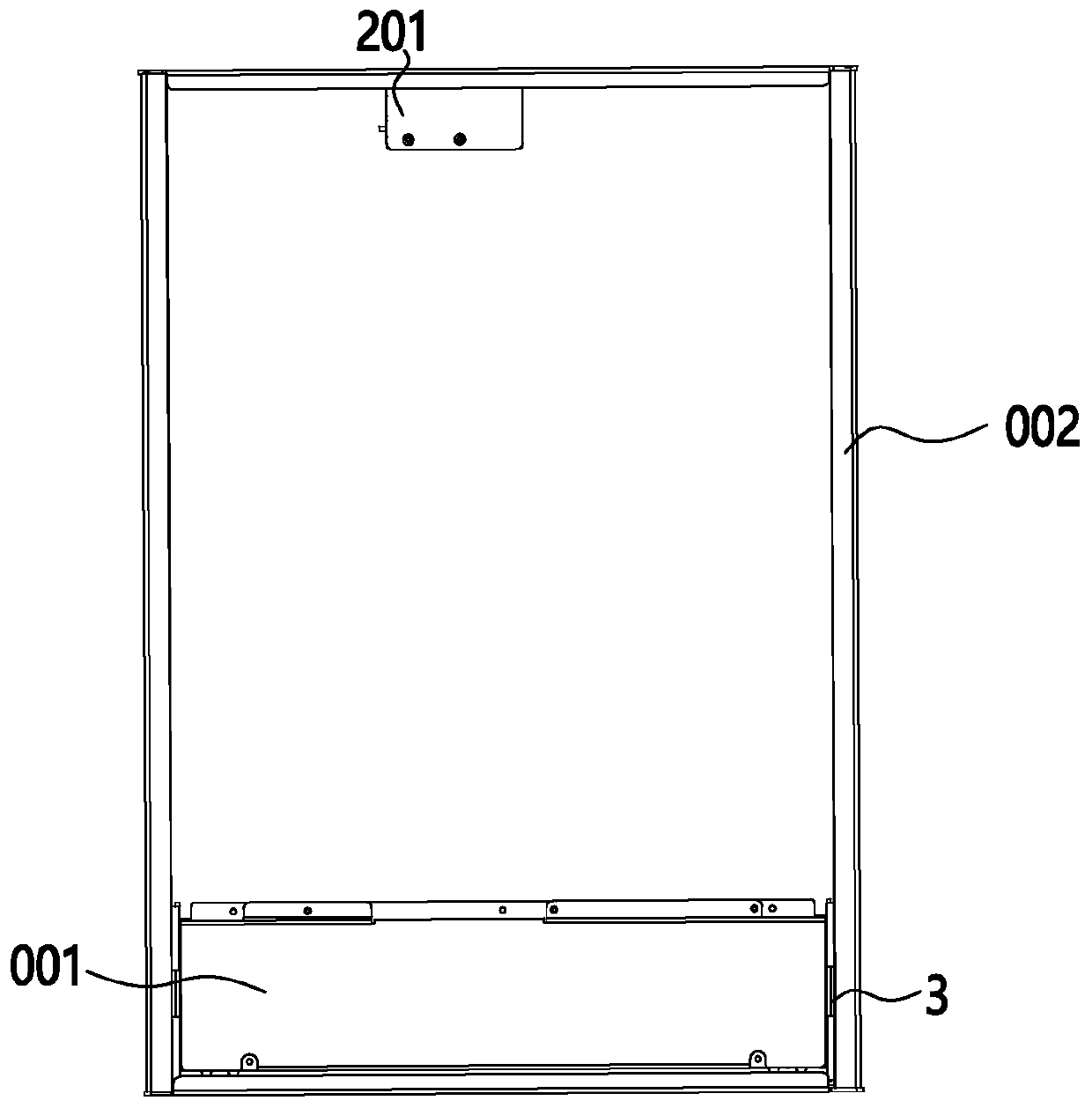

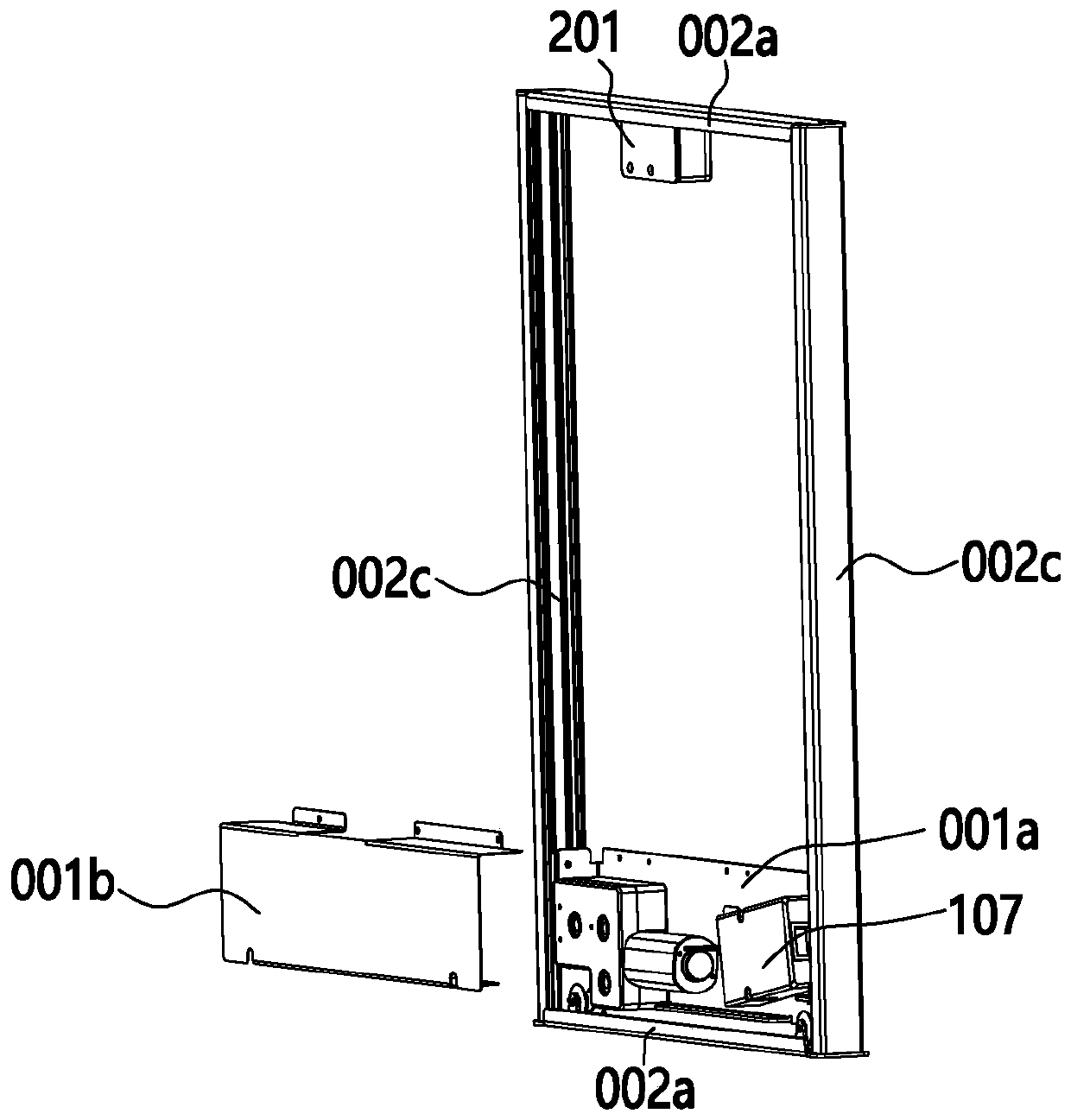

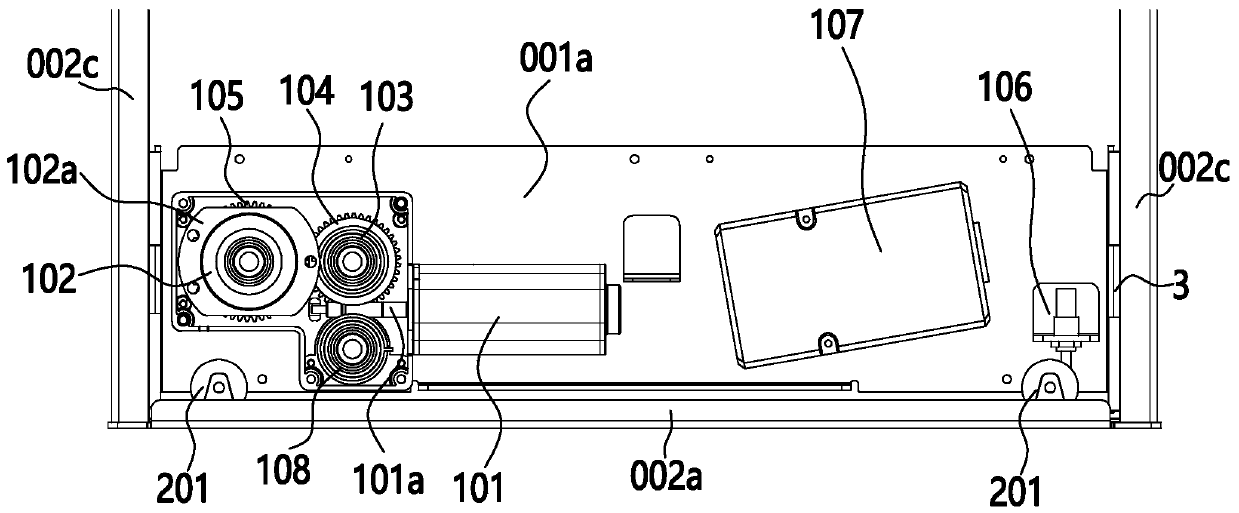

[0041] Such as Figure 1 ~ Figure 3 As shown, a lifting device for a hanging cabinet, the hanging cabinet includes a locker, and the fast lifting device includes a fixed frame 001 fixed on an external firmware, a mobile frame 002 that moves relative to the fixed frame 001, and a connection between the fixed frame 001 and the mobile frame The rope of 002, the locker is detachably connected on the mobile frame 002, the fixed frame 001 is provided with a motor 101 and the reel 102 that rotates and retracts the rope under the drive of the motor 101, drives the mobile frame 002 to move by the retracting of the rope.

[0042] The lifting device in this scheme, the fixed frame 001 can be directly fixed on the wall, or can be fixed on the outer cabinet, and connected to the mobile frame 002 as a hanging basket or an inner cabinet of the locker. The structure is simple and the installation is convenient. The motor 101 drives the reel 102 rotation, through the circumferential movement o...

Embodiment 2

[0053] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the fixed frame 001 includes a bottom plate 001a fixed on the external firmware, the reel 102 is arranged in the middle of the bottom plate 001a, and the moving frame 002 includes a lower plate 002b, and the middle of the lower plate 002b is provided with Rope fixing seat 106, one end of the rope is fixed on the reel 102, and the other end of the rope is fixed on the rope fixing seat 106.

[0054] With the above structure, the moving distance of the mobile frame 002 is equal to the length of the circumference of the reel 102, which reduces the stroke of the reel 102 and the length of the steel wire, further improves the lifting speed and shortens the lifting time.

Embodiment 3

[0056] Such as Figure 6 ~ Figure 11 As shown, the difference between this embodiment and Embodiment 1 is that a wing plate 001c is provided at the end of the bottom plate 001a of the fixed frame, and a slider assembly 03 is provided on the wing plate 001c. The slider assembly 03 includes a slider 031 and an adjustment rod. The block 031 is located between the relatively sliding wing plate 001c and the linear guide rail 002c. One end of the adjusting rod penetrates through the wing plate 001c and is connected with the slider 031. A locking structure is provided between the wing plates 001c, and the distance between the slider 031 and the linear guide rail 002c is adjusted through the expansion and contraction of the adjusting rod.

[0057] In actual operation, in order to ensure the stability of the relative sliding between the wing plate 001c and the linear guide 002c, and to avoid the resistance caused by friction to the sliding, the ideal distance between the slider 031 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com