A cryogenic electric pulse treatment method for removing residual stress of ultrafine-grained aluminum-lithium alloy strips

An aluminum-lithium alloy and residual stress technology, which is applied in the field of metal material rolling, can solve the problems of large residual stress, low toughness, and high dislocation density of materials, and achieve near-mechanical properties and low residual stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

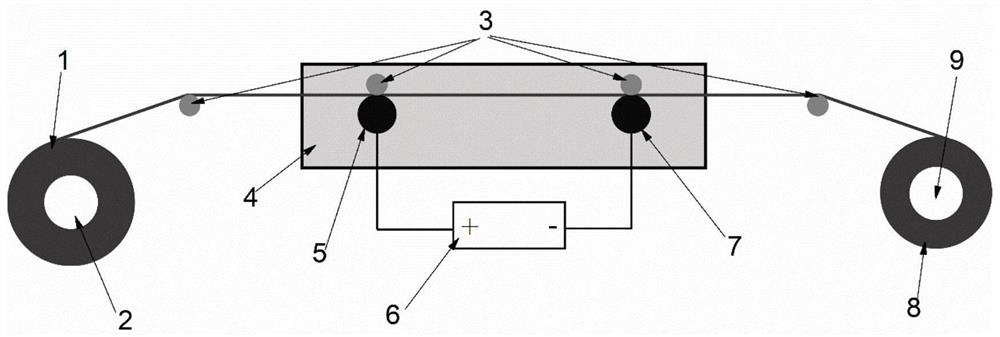

[0023] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

[0024] Ultrafine-grained aluminum-lithium alloys are more than 30% stronger than conventional aluminum-lithium alloys, and have important application prospects in the field of lightweight components. The present invention utilizes the cryogenic pulse current treatment method to eliminate the residual stress in the ultra-fine-grained aluminum-lithium alloy material, so that the grain size of the material does not change, but the dislocation density is effectively reduced, the residual stress of the material is reduced, and it is useful for subsequent material processing. The reduction of material springback in the preparation process has important application prospects. The specific principle is: in the cryogenic environment, the grain size of the aluminum-lithium alloy is stable and will not grow up. At the same time, the pulse current is used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com