High-performance enhanced halogen-free red-phosphorus-free flame-retardant PBT engineering plastic material and preparation method thereof

A kind of engineering plastics, enhanced technology, applied in the field of polymer composite materials, can solve the problems of low mechanical properties, high smoke density of materials, etc., and achieve the effect of similar flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

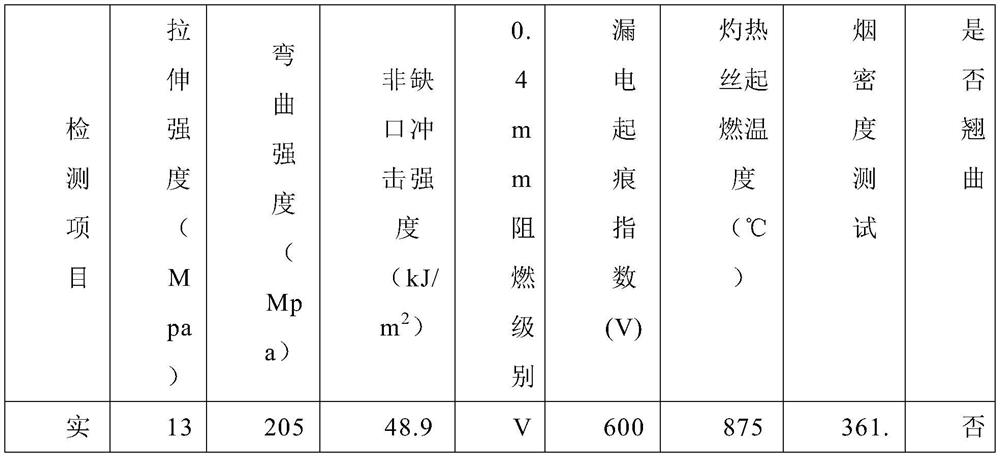

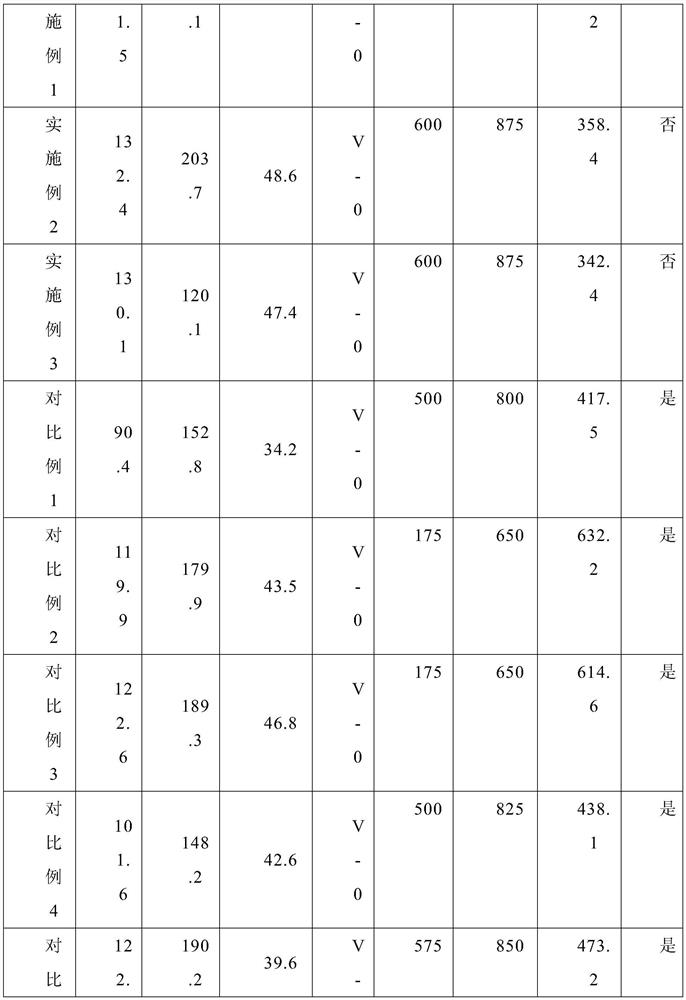

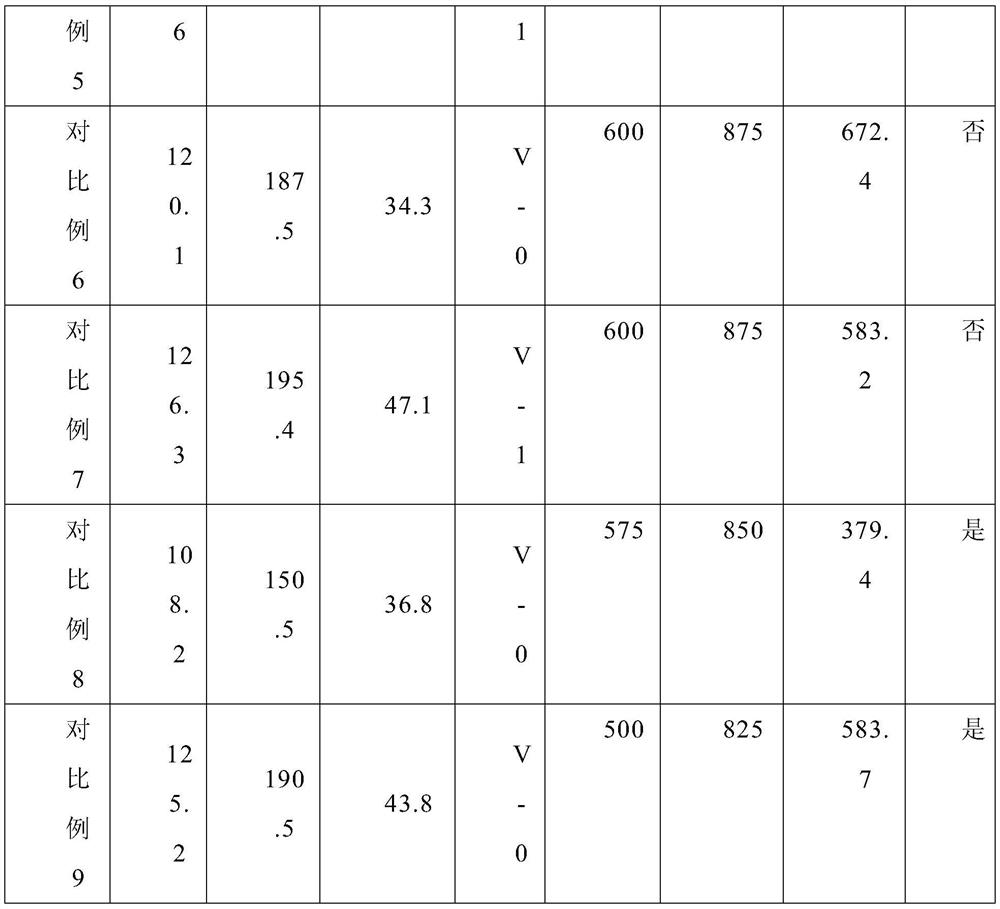

Examples

preparation example Construction

[0047] Preparation of the mineral additive: take vermiculite and grind it for 1-2 hours in an environment with a relative humidity of 55-70% to obtain a grinding material, mix the grinding material with a hydrochloric acid solution with a mass fraction of 15%, and evaporate in a vacuum to obtain a processed Material, take the processed material and add glass fiber in the mass ratio of 1:8-15 to mix, that is, the mineral additive.

[0048] The macromolecular coupling agent is glycidyl methacrylate binary copolymer.

[0049] The monomers used for the glycidyl methacrylate binary copolymer include glycidyl methacrylate and monomer X; the monomer X is vinyl chloride, ethylene terephthalate, ethylene glycol dimethyl Any one of the acrylates; the glycidyl methacrylate accounts for 12% by mass of the total monomers.

[0050] The melt index (190° C., 2.16 kg) of the obtained glycidyl methacrylate binary copolymer is greater than or equal to 100 g / 10 min.

[0051] The antioxidant is ...

Embodiment 1

[0058] A high-performance enhanced halogen-free and red phosphorus-free flame-retardant PBT engineering plastic material, the formula of the engineering plastic specifically includes the following components by mass percentage:

[0059] PBT resin: 51.2%,

[0060] Halogen-free flame retardant: 11.1%,

[0061] Flame retardant synergist: 5.1%,

[0062] Macromolecular coupling agent: 2%,

[0063] Antioxidant: 0.5%,

[0064] Mineral additives: 30.1%.

[0065] Specifically, the relative viscosity of the PBT material is 0.8.

[0066] Specifically, the said halogen-free flame retardant is OP1240 grade halogen-free flame retardant produced by Klein Company.

[0067] Specifically, the flame retardant synergist is melamine polyphosphate.

[0068] Specifically, the preparation of the mineral additive: take vermiculite and grind it for 1 hour in an environment with a relative humidity of 55% to obtain a grinding material, mix the grinding material with a hydrochloric acid solution wi...

Embodiment 2

[0081] A high-performance enhanced halogen-free and red phosphorus-free flame-retardant PBT engineering plastic material, the formula of the engineering plastic specifically includes the following components by mass percentage:

[0082] PBT resin: 52%,

[0083] Halogen-free flame retardant: 10.1%,

[0084] Flame retardant synergist: 5.1%,

[0085] Macromolecular coupling agent: 2%,

[0086] Antioxidant: 0.5%,

[0087] Mineral additives: 30.3%.

[0088] Specifically, the relative viscosity of the PBT engineering plastic is 0.8.

[0089] Specifically, the preparation of the mineral additive: take vermiculite and grind it for 2 hours in an environment with a relative humidity of 65% to obtain a grinding material, mix the grinding material with a hydrochloric acid solution with a mass fraction of 15%, and evaporate in a vacuum to obtain a treatment material , take the processing material and add glass fiber in a mass ratio of 1:8 to mix, that is, mineral additives.

[0090] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com