Wet maintenance method during shutdown of secondary circuit of nuclear power plant

A technology for secondary circuit and wet maintenance of nuclear power plants, which is applied in the field of wet maintenance methods during the shutdown of secondary circuits of nuclear power plants, can solve the problems of self-corrosion consumption, low current efficiency, influence on flushing progress, unpublished papers, patents and standards, etc. Achieving the effect of shortening the time to start flushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with specific examples.

[0048] The embodiment of the present invention is based on the application practice and experience summary during the previous outage periods of Sanmen Nuclear Power Plant No. Humidity protection during operation to minimize equipment corrosion during system outages.

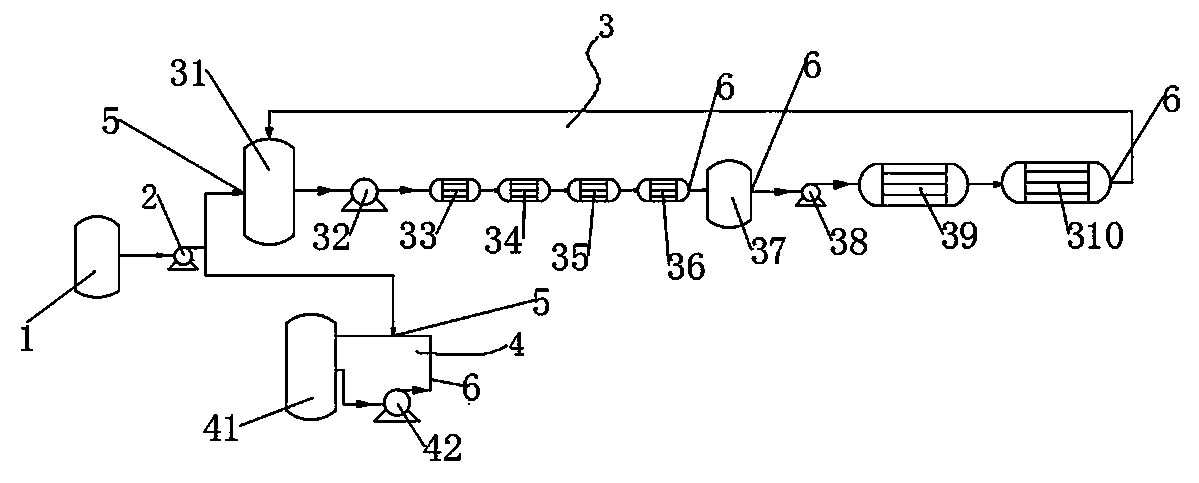

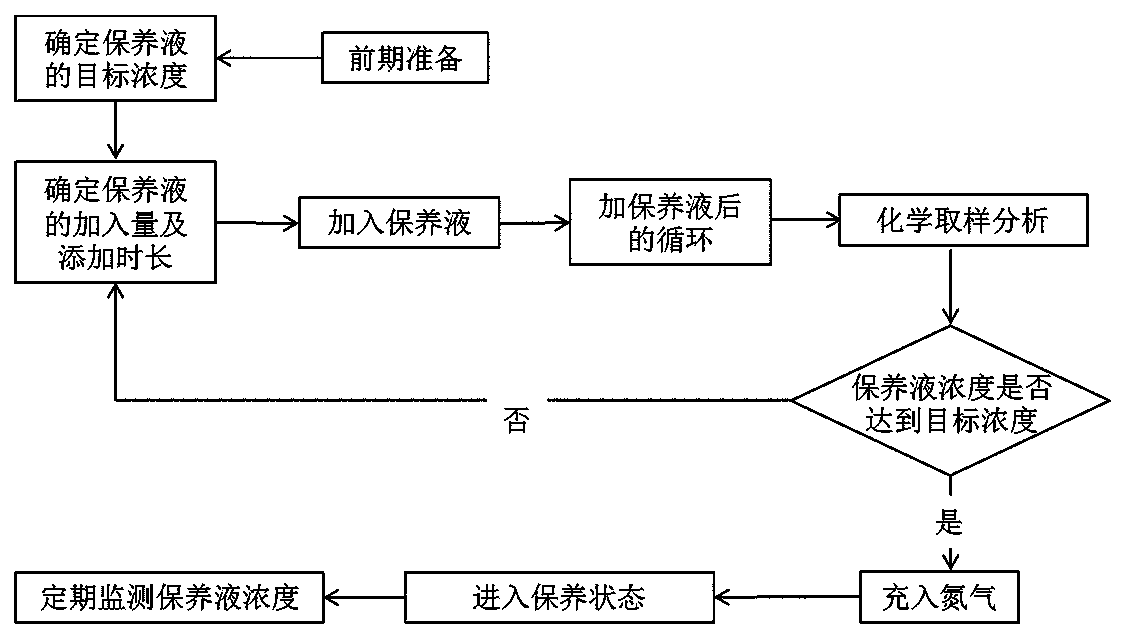

[0049] figure 2 It is a system schematic diagram of a wet maintenance method during the outage of the secondary circuit of a nuclear power plant, refer to figure 2 , the maintenance system includes maintenance fluid storage tank 1 for storing maintenance fluid, dosing pump 2 for adding maintenance fluid to the system, condensate and water supply system for secondary circulating water 3, steam generator system 4, dosing Point 5 and sampling point 6; the condensate and water supply system 3 includes condenser 31, condensate pump 32, 1# low pressure heater 33, 2# low pressure heater 34, 3# low pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com