A kind of chemical wet maintenance method during shutdown of auxiliary boiler in nuclear power plant

An auxiliary boiler and wet maintenance technology, applied in the direction of scientific instruments, instruments, analytical materials, etc., can solve the problems of heavy supervision tasks, increased maintenance costs, high costs, etc., and achieve the effects of guaranteed maintenance quality, reduced costs, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

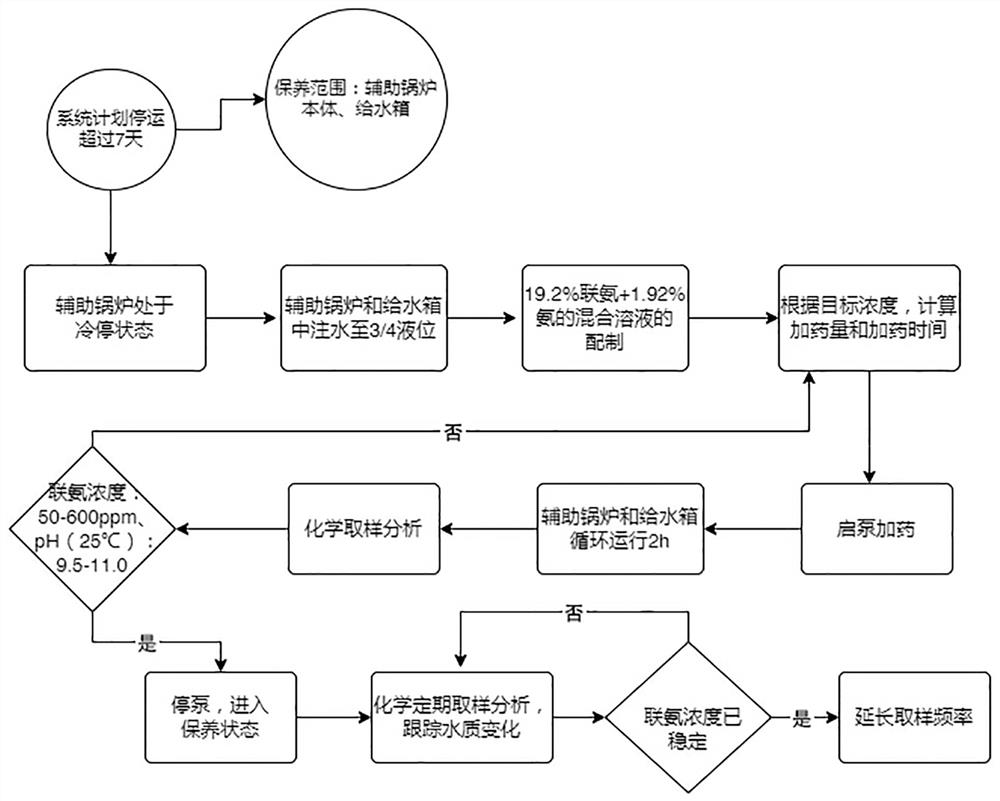

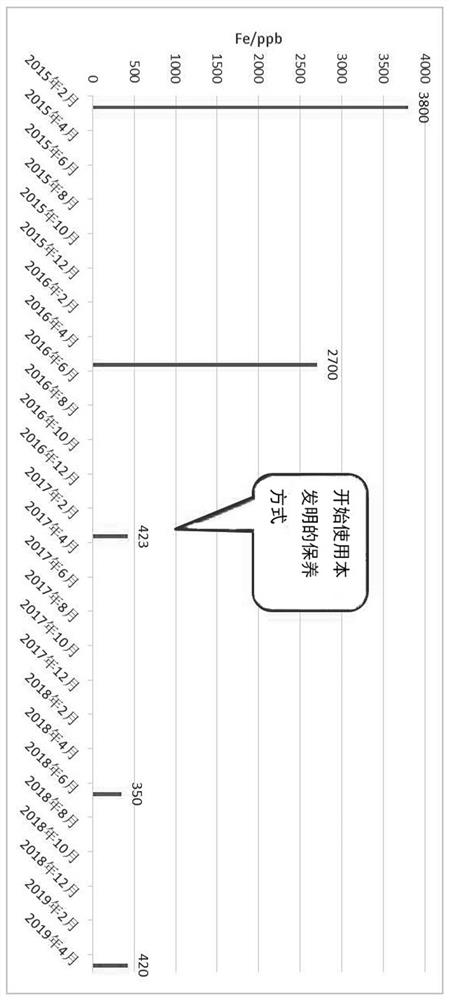

[0068] In January 2019, the auxiliary boiler system of the Sanmen nuclear power plant was out of service. The outage time exceeded 7 days and maintenance was required. This embodiment provides a chemical wet maintenance method during the outage of the auxiliary boiler of the nuclear power plant to assist the boiler, feed water tank As the maintenance target, the hydrazine concentration in the auxiliary boiler and feed water tank is 50-600ppm, and the pH (25°C) is 9.5-11.0 as the maintenance index; the maintenance process is as follows figure 1 As shown, it specifically includes the following steps:

[0069] S1. System water intake: fill the auxiliary boiler and feed water tank to 3 / 4 liquid level;

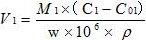

[0070] S2. Dispensing: Prepare ammonia water with a concentration of 25% and hydrazine stock solution with a concentration of 51.2%, add them to the dosing box, and make a mixed solution of 19.2% hydrazine + 1.92% ammonia as a maintenance solution. The amount of ammonia stock solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com