Bridge water dripping groove structure

A technology of dripping tanks and structures, applied in bridges, bridge construction, bridge parts, etc., can solve problems such as deterioration, affecting the durability of bridge main girders, side beams, clean and beautiful appearance, concrete corrosion, etc., to achieve excellent weather resistance and increase the partition effect , good water resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

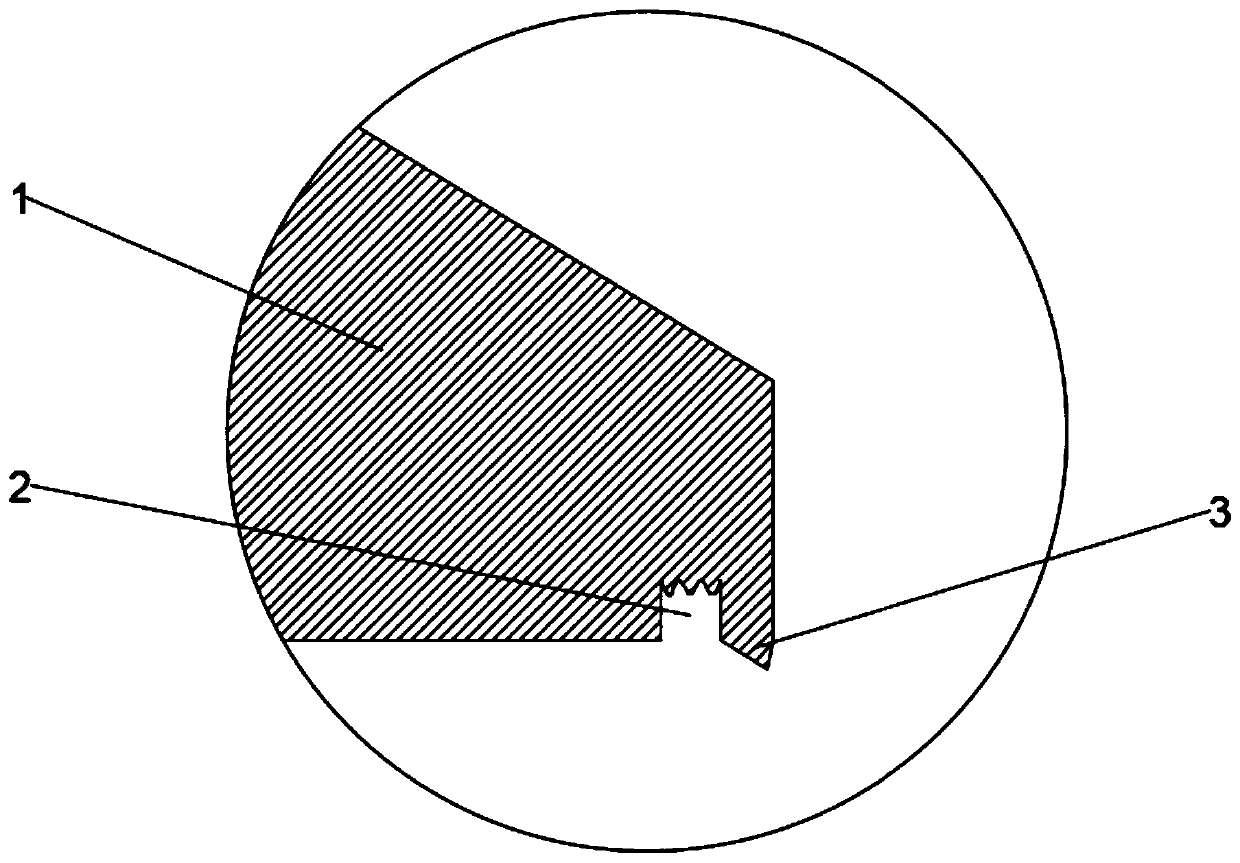

[0045] A bridge drip tank construction such as figure 1 As shown, it includes a side beam flange plate 1 and a drip groove 2, and the drip groove 2 is arranged at a position close to the lower edge end of the side beam flange plate 1; the shape of the drip groove 2 is a U-shaped opening downward; the Between the drip groove 2 and the end of the lower edge of the side sill flange 1 is formed a sharp-edged edge guard 3 protruding downwards, which is thin on the outside and thick on the inside.

[0046] The end of the drip groove 2 away from the opening is configured as a corrugated structure.

[0047] The inner surface of the drip tank 2 and the surface of the edge protection 3 are all coated with a polymer cement waterproof and anti-corrosion coating.

[0048] The polymer cement waterproof and anticorrosion coating is composed of a solid component and a liquid component;

[0049] The liquid component consists of the following components in parts by weight:

[0050] 55 parts ...

Embodiment 2

[0078] A bridge drip tank construction such as figure 1 As shown, it includes a side beam flange plate 1 and a drip groove 2, and the drip groove 2 is arranged at a position close to the lower edge end of the side beam flange plate 1; the shape of the drip groove 2 is a U-shaped opening downward; the Between the drip groove 2 and the end of the lower edge of the side sill flange 1 is formed a sharp-edged edge guard 3 protruding downwards, which is thin on the outside and thick on the inside.

[0079] The end of the drip groove 2 away from the opening is configured as a corrugated structure.

[0080] The inner surface of the drip tank 2 and the surface of the edge protection 3 are all coated with a polymer cement waterproof and anti-corrosion coating.

[0081] The polymer cement waterproof and anticorrosion coating is composed of a solid component and a liquid component;

[0082] The liquid component consists of the following components in parts by weight:

[0083] 45 parts ...

Embodiment 3

[0111] A bridge drip tank construction such as figure 1 As shown, it includes a side beam flange plate 1 and a drip groove 2, and the drip groove 2 is arranged at a position close to the lower edge end of the side beam flange plate 1; the shape of the drip groove 2 is a U-shaped opening downward; the Between the drip groove 2 and the end of the lower edge of the side sill flange 1 is formed a sharp-edged edge guard 3 protruding downwards, which is thin on the outside and thick on the inside.

[0112] The end of the drip groove 2 away from the opening is configured as a corrugated structure.

[0113] The inner surface of the drip tank 2 and the surface of the edge protection 3 are all coated with a polymer cement waterproof and anti-corrosion coating.

[0114] The polymer cement waterproof and anticorrosion coating is composed of a solid component and a liquid component;

[0115] The liquid component consists of the following components in parts by weight:

[0116] 65 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com