Sealing structure for penetrating hole of color steel plate

A technology of sealing structure and color steel plate, applied in the direction of pipes, electrical components, pipes/pipe joints/pipe fittings, etc., can solve the problems of poor resistance to micro-vibration, easy damage, and poor sealing effect of pipelines, and achieve improved airtightness , to meet the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

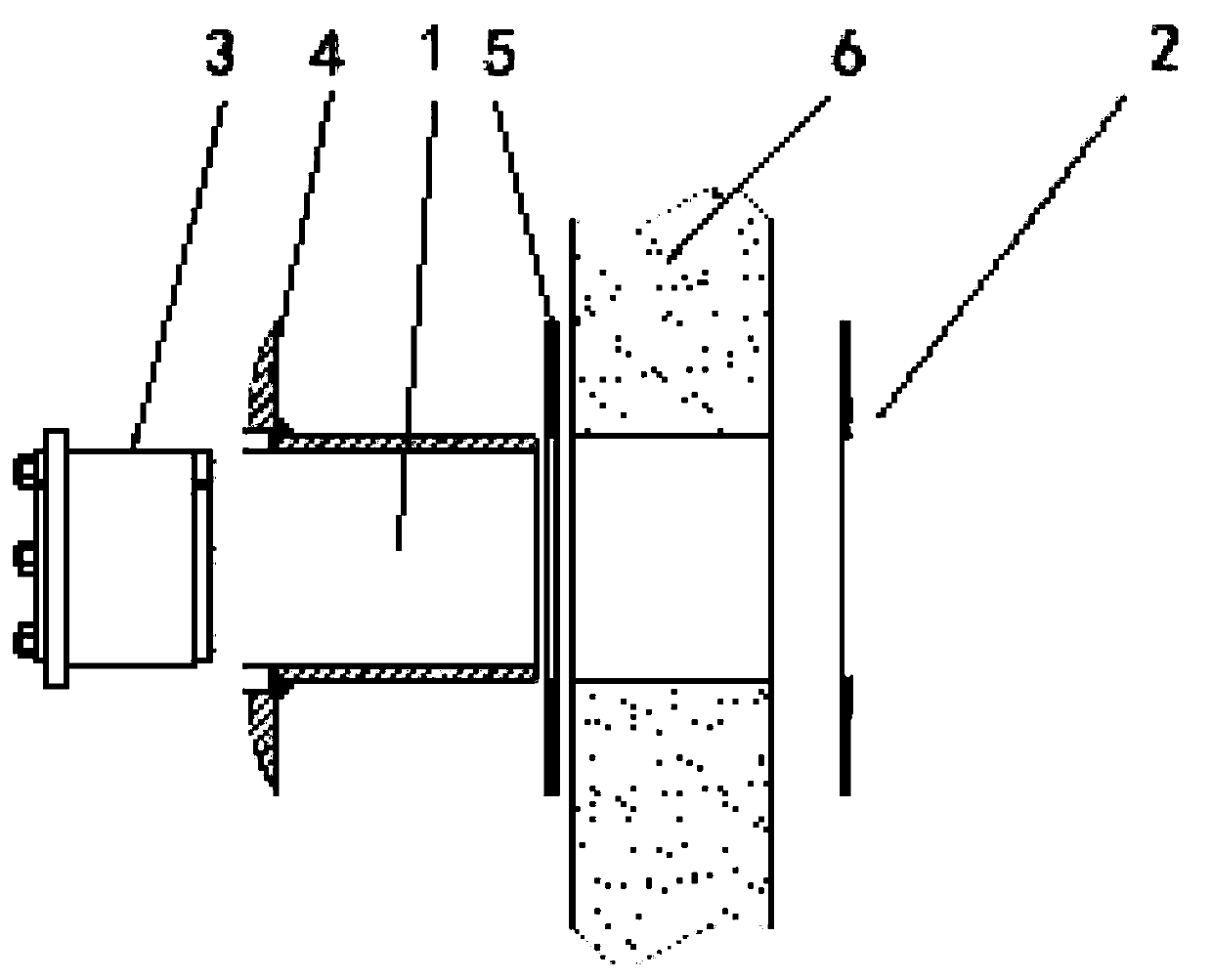

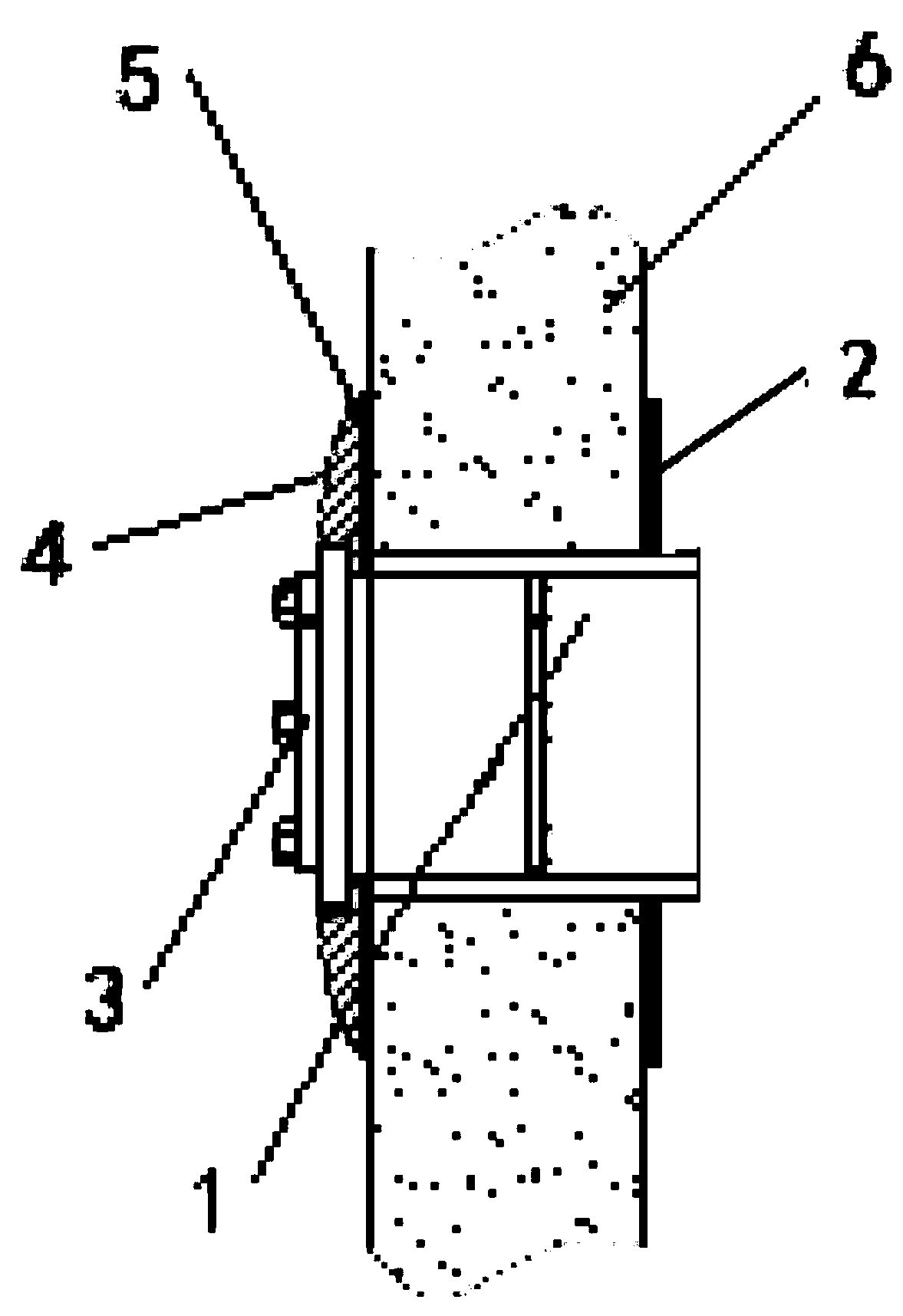

[0031] A kind of sealing structure of color steel plate penetrating holes in this embodiment, such as figure 1 , 2 As shown, it includes a main frame, a wafer flange 2 and an MCT sealing module 3. The main frame includes a casing main body 1 and a flange 4, and the flange 4 is located at one end of the casing main body 1, so The MCT sealing module 3 is adapted to the casing main body 1 . A gasket 5 is arranged between the flange 4 and the surface of the color steel plate 6 .

[0032] The diameter of the casing main body 1 is adapted to the hole and the length is 12mm longer than the color steel plate 6 hole, and the thickness is 4mm. The width is 35mm, and the slope transitions smoothly from the thickest point to the edge.

[0033] The wafer flange 2 has a thickness of 3 mm and a width of 35 mm, and a gasket (not shown) may also be provided between the flange and the color steel plate 6 .

[0034] When the cables and pipes pass through the color steel plate, the casing bod...

Embodiment 2

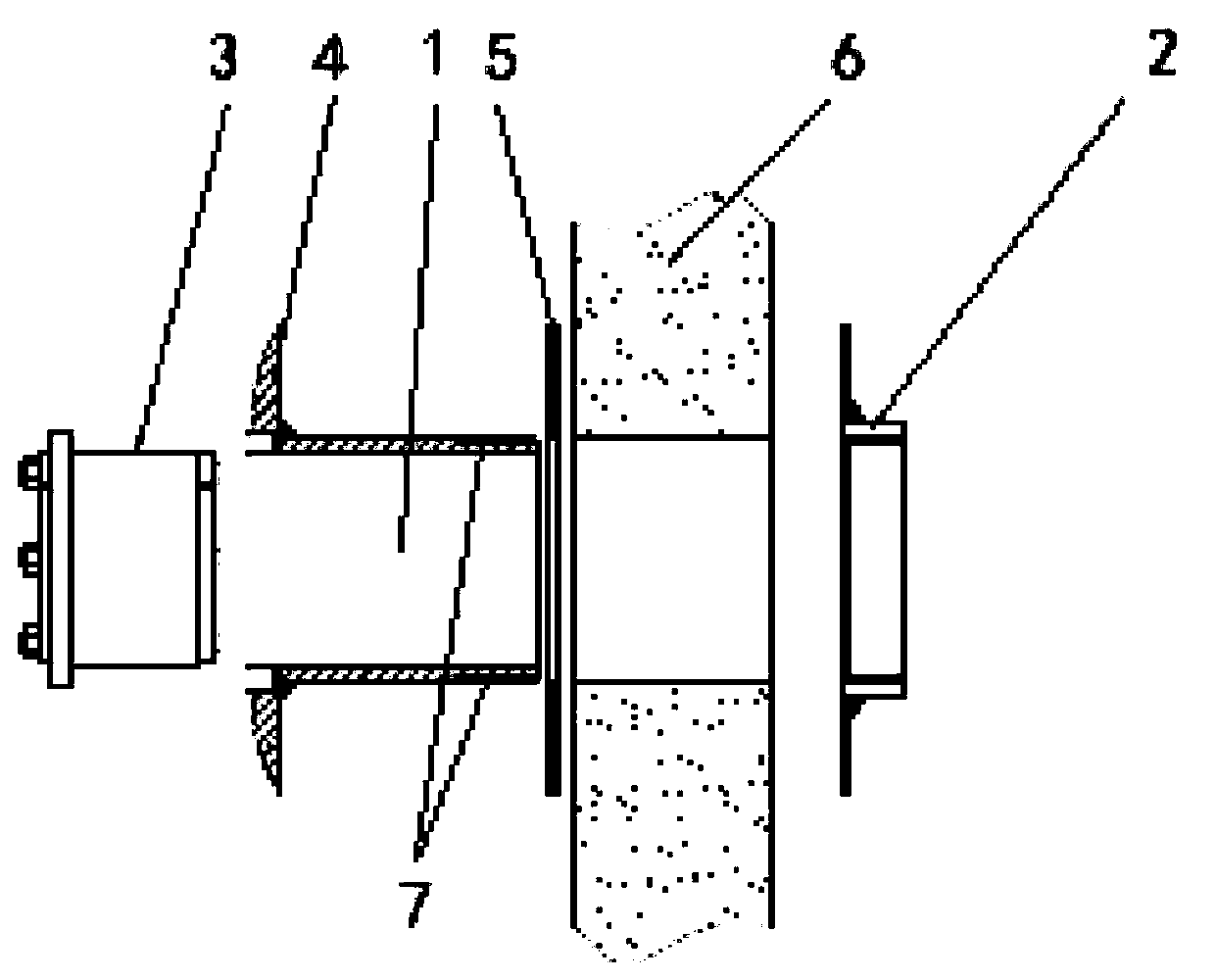

[0036] A kind of sealing structure of color steel plate penetrating holes in this embodiment, such as Figure 3-9 As shown, the difference from Embodiment 1 is that the other end of the sleeve body 1 has an external thread 7 fixed to the wafer flange 2, and the inner side of the wafer flange 2 also has an internal thread corresponding to the external thread 7 8.

[0037] The diameter of the casing main body 1 is adapted to the hole and the length is 8mm longer than the color steel plate 6 holes, and the thickness is 2mm. The width is 25mm, and the slope from the thickest point transitions smoothly to the edge, and there is a 5mm groove 9 inside the flange 4, so that the MCT sealing module 3 can fit well.

[0038] The wafer flange 2 has a wafer flange sleeve 10 with a depth of 5 mm and a thickness of 5 mm, and the outer side of the wafer flange sleeve 10 has a 5 mm cutout 11 at a position opposite to a certain diameter for use during installation. Tool tightens. The flange p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com