Automatic hanging type drying and cooling device

A cooling device, hanging technology, applied in the field of mechanical processing, can solve the problems of insufficient product drying, affecting product cleanliness, large floor space, etc., to avoid the outflow of unqualified products, avoid cleanliness problems, and save space. effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

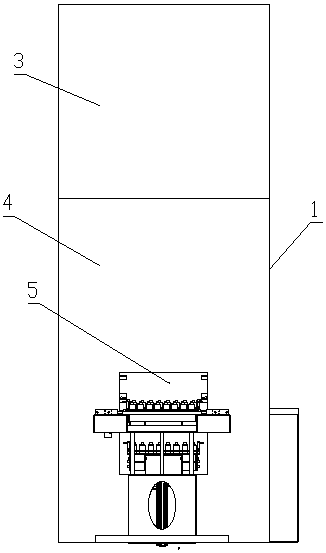

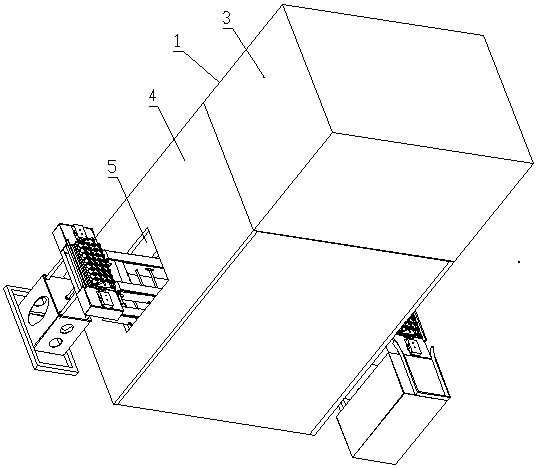

[0044] Such as Figure 1 to Figure 8 As shown, the automatic hanging drying and cooling device of the present invention includes a drying box 1 and several trays 2, and the drying box 1 is divided up and down with a drying chamber 3 positioned at the top and a cooling chamber 4 positioned at the bottom; the cooling chamber The lower part of 4 is provided with a left opening 5 and a right opening 6 opposite to each other;

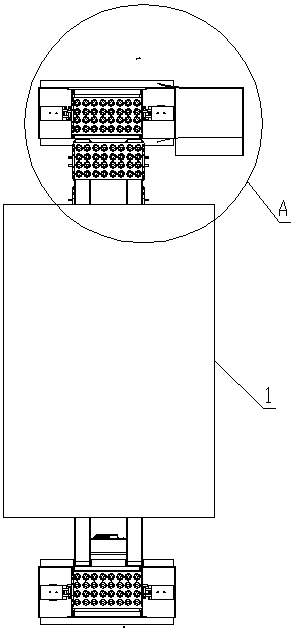

[0045] The left opening 5 is provided with a feed conveyor belt mechanism 7 arranged horizontally, and the feed conveyor belt mechanism 7 is used to send the product to be dried from the outside of the drying box 1 into the drying box 1;

[0046] The right opening 6 is provided with a horizontally arranged discharge conveyor belt mechanism 8, which is used to send the dried product out of the drying box 1; the feed conveyor belt mechanism 7 and the discharge conveyor belt mechanism 8, the feeding direction is from left to right;

[0047] The structure of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com