Method for realizing online inspection and replacement of gas holder heat tracing system

A replacement method and technology for gas cabinets, which are applied in the testing of machinery/structural components, instruments, measuring devices, etc., can solve problems such as water overflow in heating circulating water, gas backflow heating pipes, hidden dangers, etc., and reduce maintenance costs. The effect of saving resources, saving maintenance time, and reducing gas emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further illustrated below by specific examples.

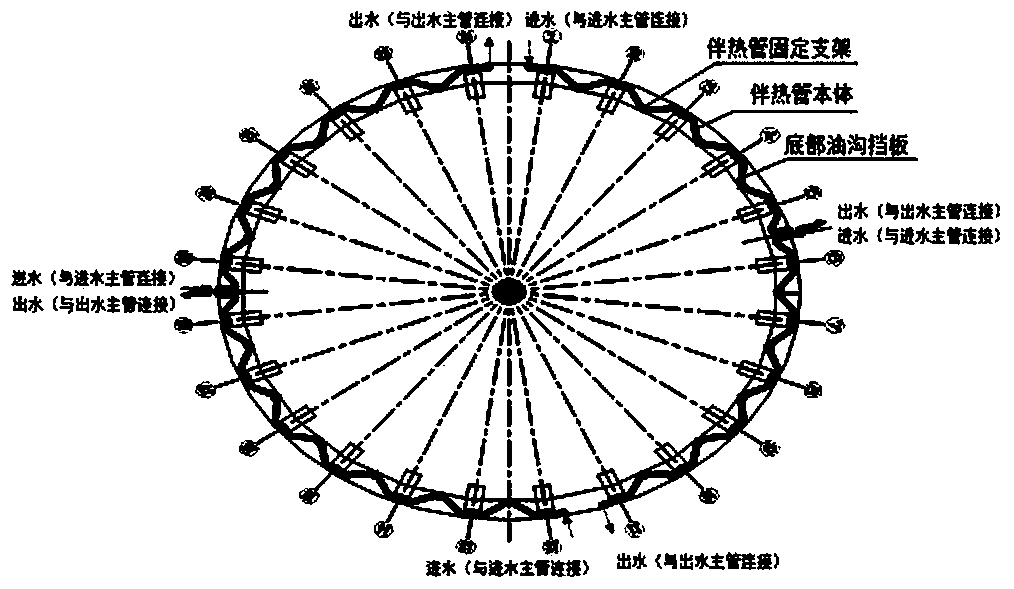

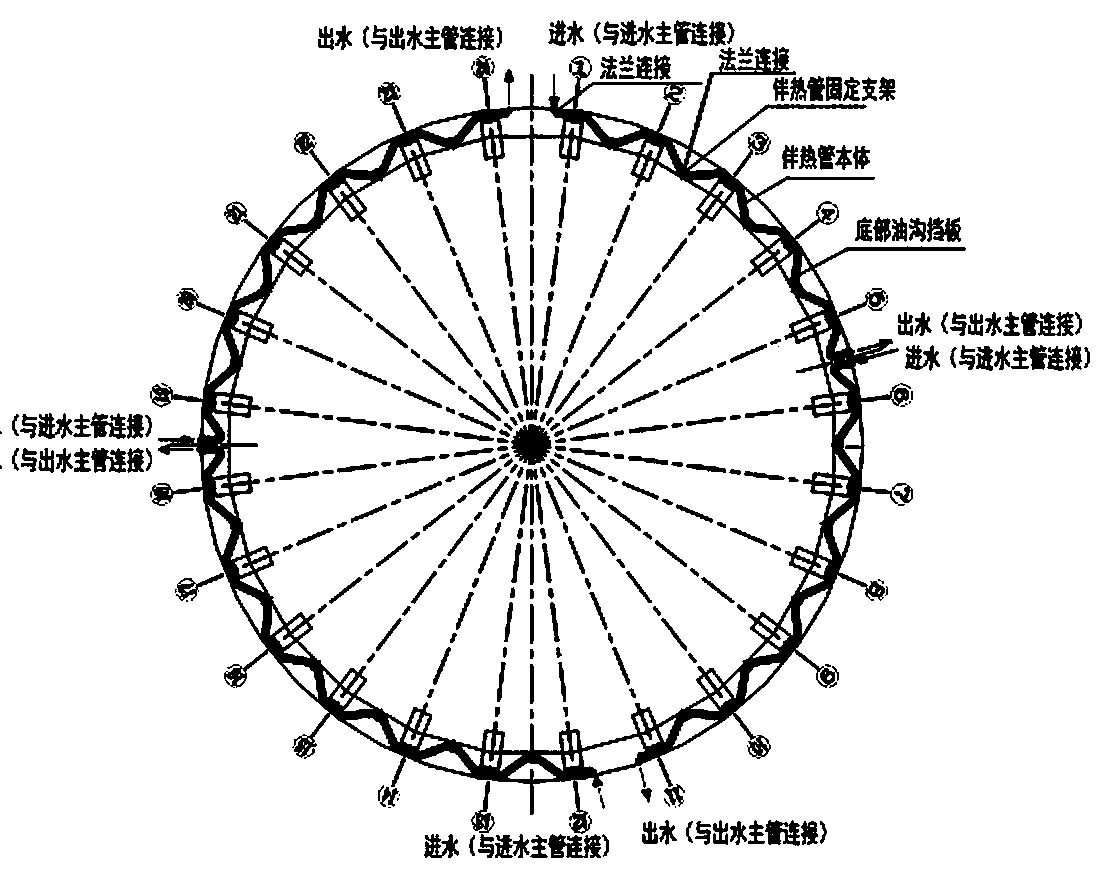

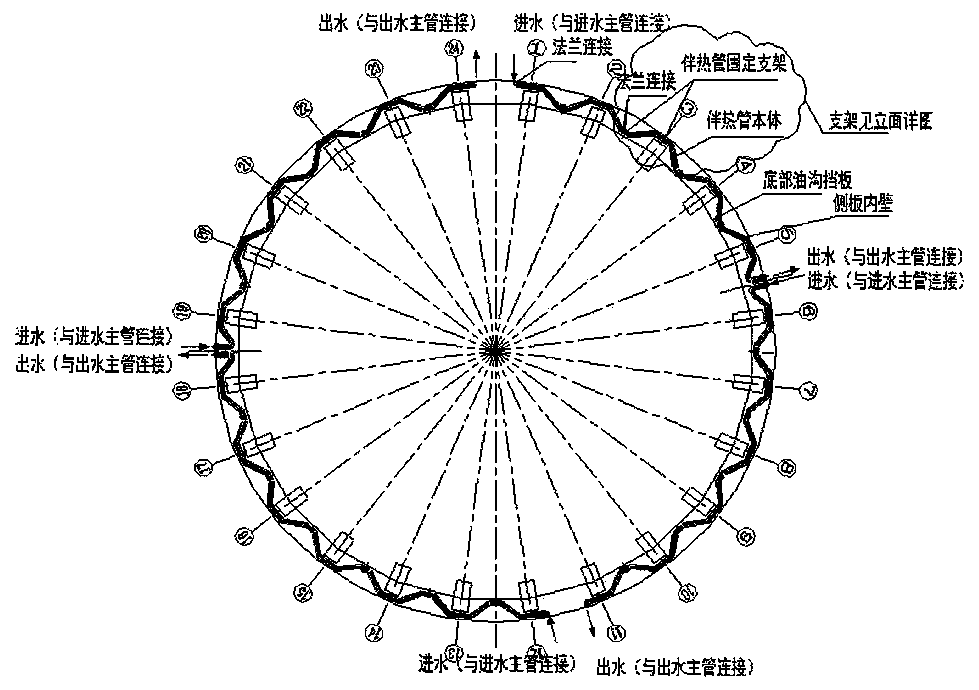

[0024] Such as Figure 1~Figure 4 As shown, a method for realizing the online inspection and replacement of the heat tracing system of the gas cabinet, including

[0025] Step 1. Transformation of the heat tracing system of the gas cabinet:

[0026] Step 1.1. Divide the main body of the heating pipe in the cabinet into 4~6 groups, each group is divided into several small sections, and the connection method of each small section is flange connection, so that each group can be dismantled and replaced by sections; Each section does not exceed 15m;

[0027] Step 1.2. Build the overall upgrading and replacement system of the heating pipes in the cabinet: In the past, when the heating pipes in the oil ditch at the bottom of the gas cabinet were found to be leaking and needed to be repaired, the 100 tons of sealed oil in the cabinet should be taken out of the container for temporary storage, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com