Bottom sinking type automatic surface water sampling system

A surface water and water harvesting technology, which is applied in the direction of testing water, sampling devices, and preparation of test samples, can solve the problems of slow water flow and the inability to collect representative water samples in the water harvesting system, and achieve low construction costs and high operational efficiency. Low maintenance cost and good operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

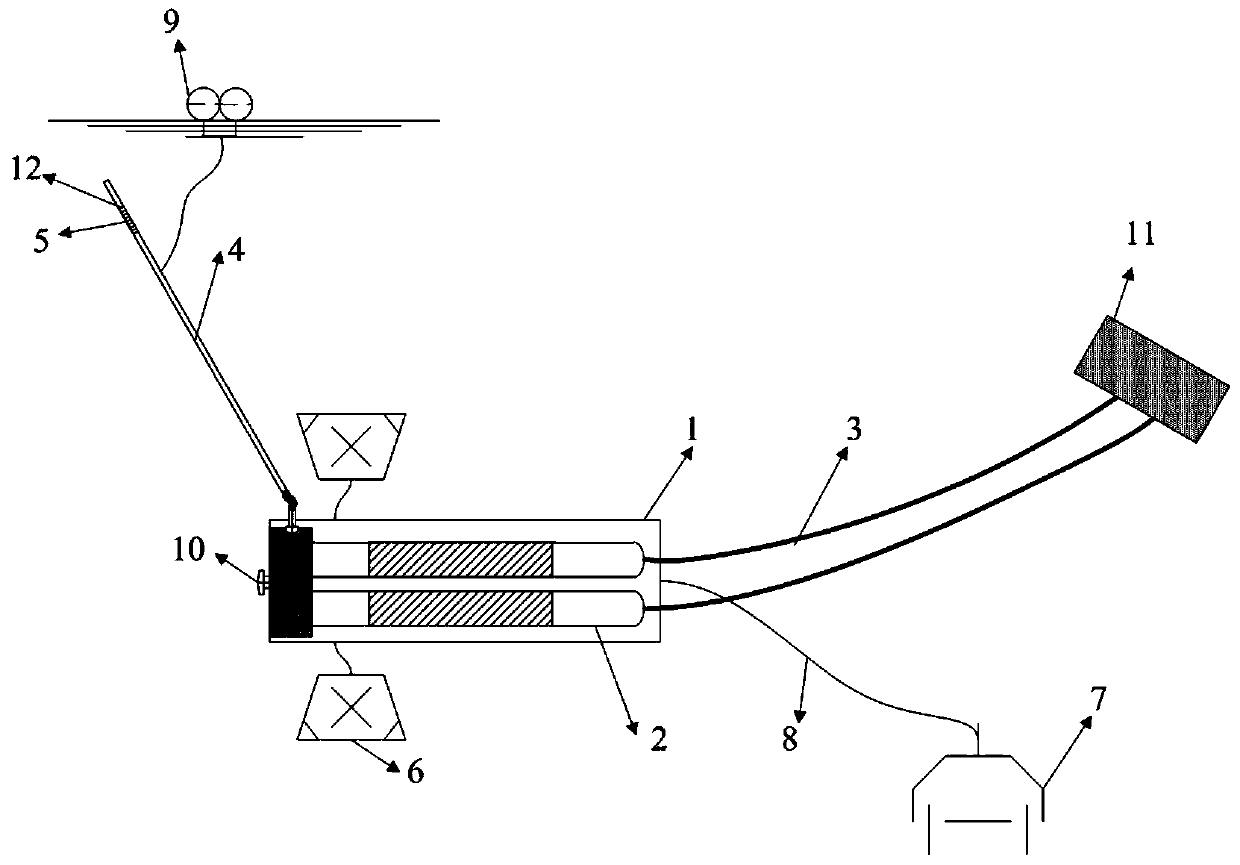

[0023] The water collection system of a river surface water automatic monitoring station consists of 1 water tank, 2 water pumps, 3 pipelines, 4 floating rods, 5 filters, 6 heavy blocks, 7 fixed piles, 8 fixed steel cables, 9 floats, 10 sand discharge Inlet, 11 control unit and 12 water inlet holes, two 2 water collection pumps are placed in the airtight 1 water tank, 2 water collection pumps are connected to the water inlet and outlet pipelines, 4 floating rods are softly connected to the water inlet of 1 water tank, and there are 10 rows at the bottom of the water tank In Shakou, in order to prevent the water tank from being washed away, 6 heavy blocks are connected to both sides of the 1 water tank, and the water tank is fixed to the 7 fixed piles with 8 fixed steel cables. The surface water enters the water tank 1 from the water inlet hole of the floating rod 12, and is sent to the pretreatment unit of the automatic water quality monitoring station by the 2 water collection...

Embodiment 2

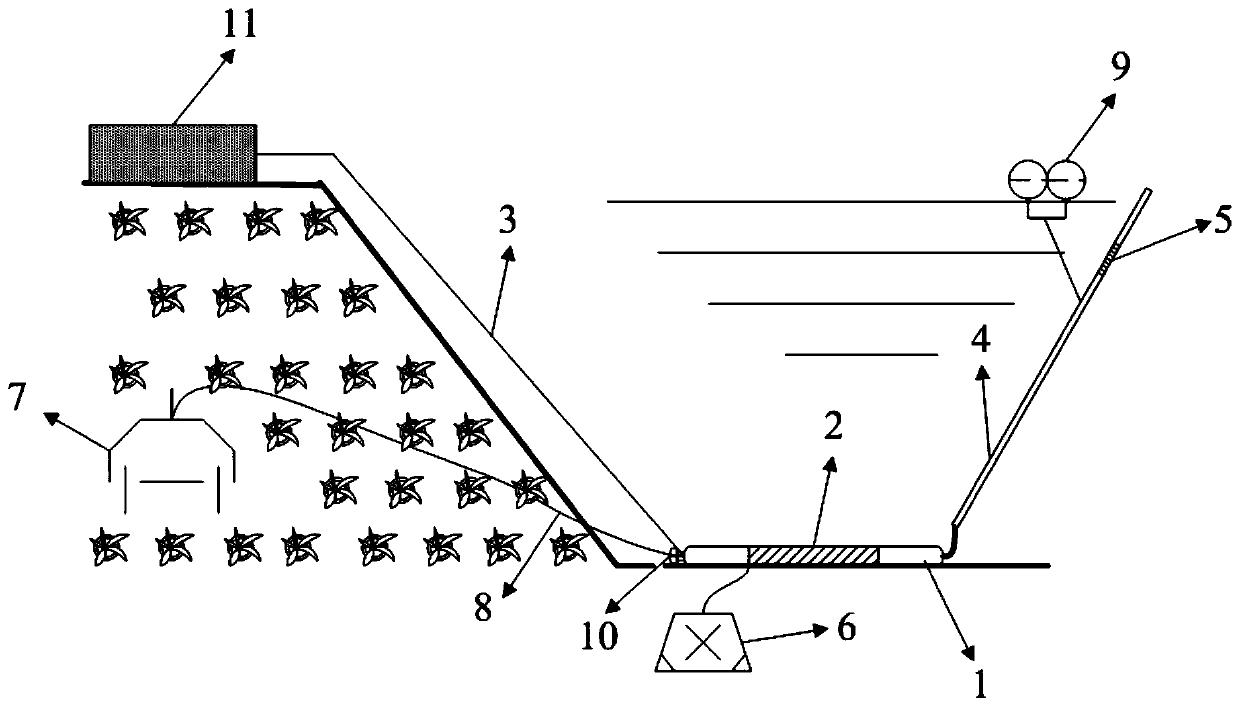

[0026] The water collection system of a surface water automatic monitoring station in a reservoir consists of 1 water tank, 2 water pumps, 3 pipelines, 4 floating rods, 5 filters, 6 heavy blocks, 7 fixed piles, 8 fixed steel cables, 9 floats, 10 sand discharge Inlet, 11 control unit and 12 water inlet holes, two 2 water collection pumps are placed in the airtight 1 water tank, 2 water collection pumps are connected to the water inlet and outlet pipelines, 4 floating rods are softly connected to the water inlet of 1 water tank, and there are 10 rows at the bottom of the water tank In Shakou, in order to prevent the water tank from being washed away, 6 heavy blocks are connected to both sides of the 1 water tank, and the water tank is fixed to the 7 fixed piles with 8 fixed steel cables. The surface water enters the water tank 1 from the water inlet hole of the floating rod 12, and is sent to the pretreatment unit of the automatic water quality monitoring station by the 2 water c...

Embodiment 3

[0029] The water collection system of a lake surface water automatic monitoring station consists of 1 water tank, 2 water pumps, 3 pipelines, 4 floating rods, 5 filters, 6 heavy blocks, 7 fixed piles, 8 fixed steel cables, 9 floats, 10 sand discharge Inlet, 11 control unit and 12 water inlet holes, two 2 water collection pumps are placed in the airtight 1 water tank, 2 water collection pumps are connected to the water inlet and outlet pipelines, 4 floating rods are softly connected to the water inlet of 1 water tank, and there are 10 rows at the bottom of the water tank In Shakou, in order to prevent the water tank from being washed away, 6 heavy blocks are connected to both sides of the 1 water tank, and the water tank is fixed to the 7 fixed piles with 8 fixed steel cables. The surface water enters the water tank 1 from the water inlet hole of the floating rod 12, and is sent to the pretreatment unit of the automatic water quality monitoring station by the 2 water collection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com