Multi-layer food retail machine convenient to take and place and working method thereof

A technology for retail machines and food, applied in the direction of coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, coinless or similar appliances, etc., which can solve the problem of poor accuracy and stability and other problems to achieve the effect of improving efficiency, overcoming low efficiency, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

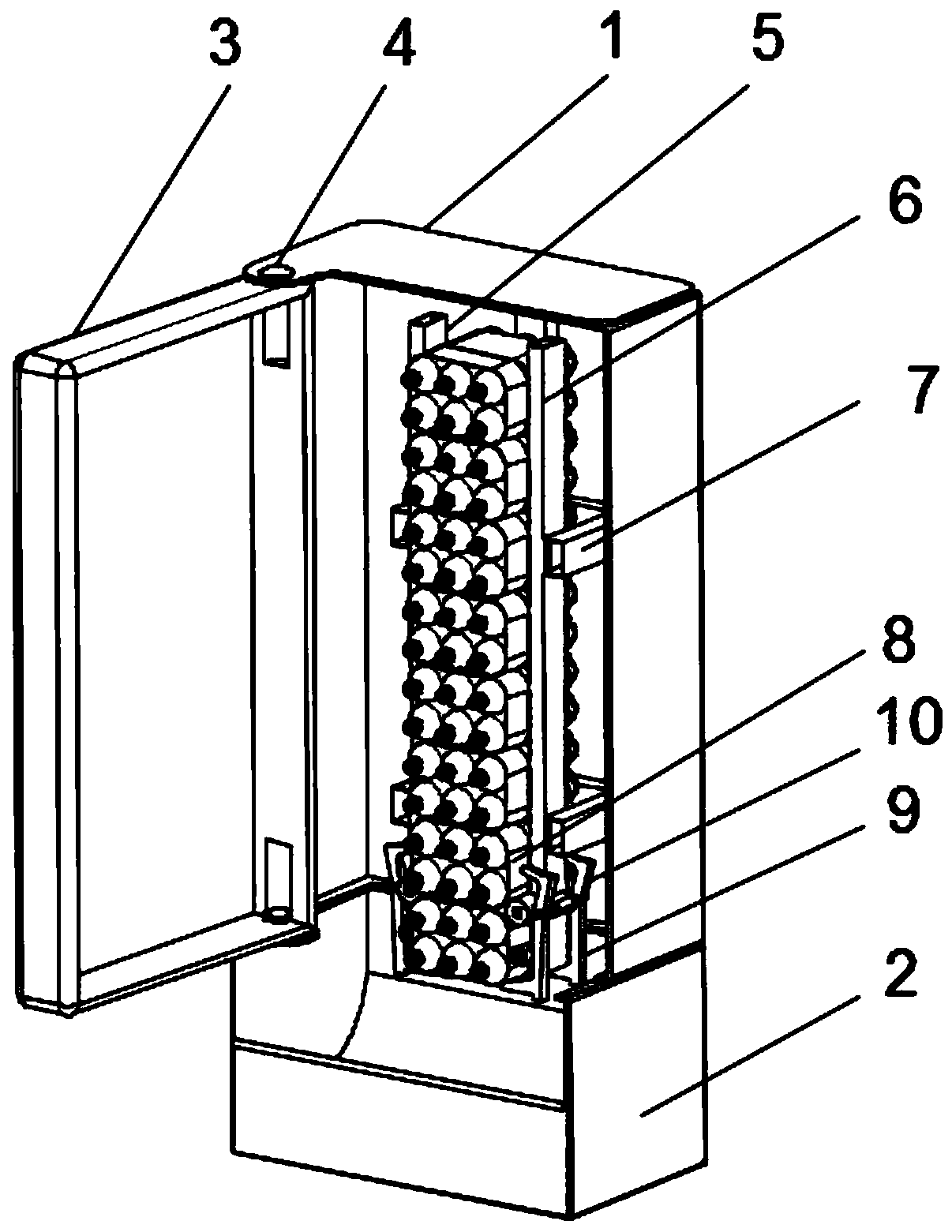

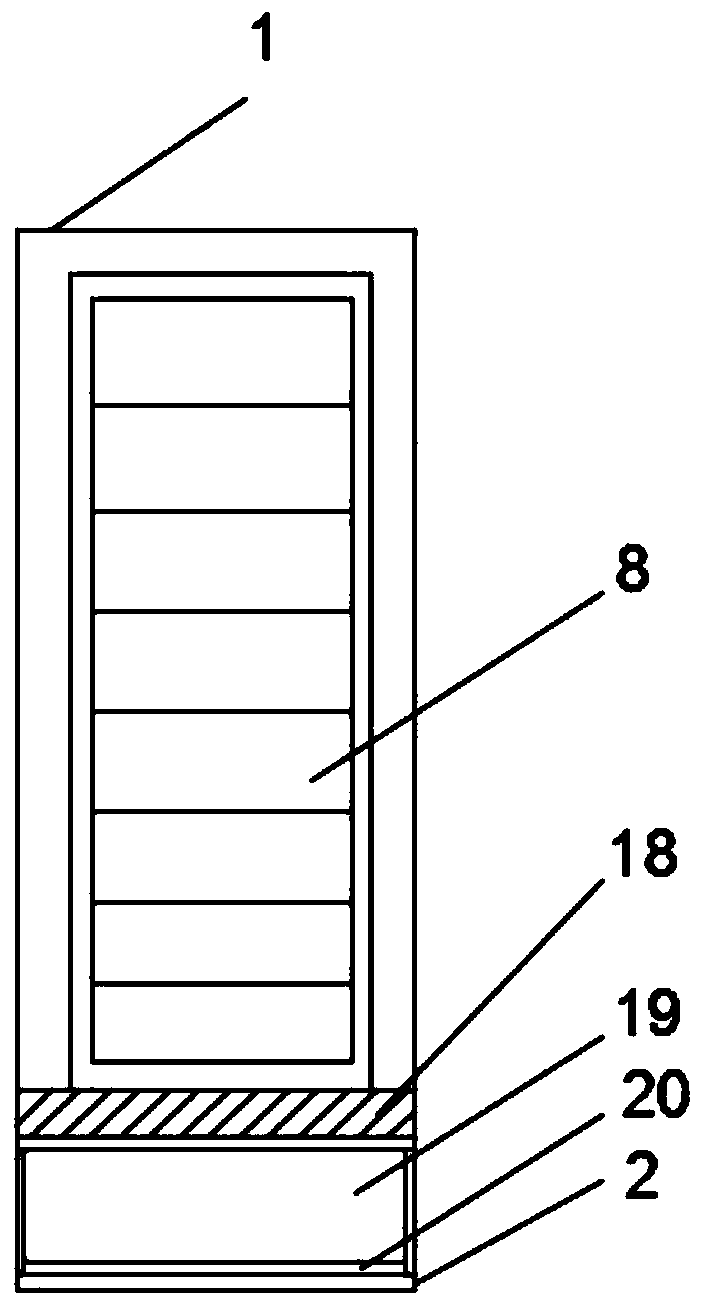

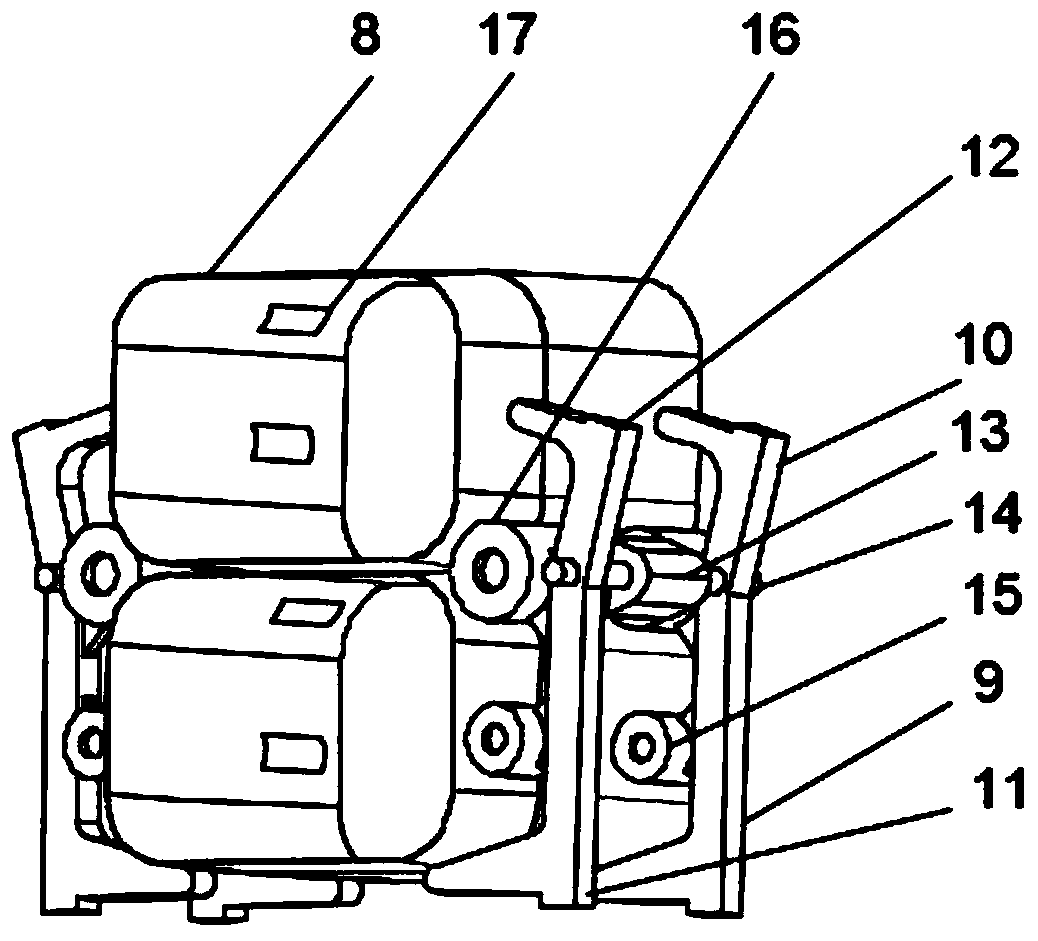

[0048] There is a food retail machine B in the shopping mall A. The staff turns the revolving door 3 outward through the rotating shaft 4, so that the inside of the retail machine body 1 is opened, and slides and inserts the food into the storage tube 8 in sequence until several storage tubes 8 is filled with food, the staff places the storage tube 8 inside the retail machine body 1, the storage tube 8 slides down through several first drums 15 and second drums 16, and enters the first fixed column 5 and the second drum. The position between the two fixed columns 6, the bottom end of the storage tube 8 is located near the inner surface of the first support base 9 and the second support base 11, and the staff will place several storage tubes 8 in a vertical state in turn to the inside of the retail machine body 1, so that the food is in different layers inside the retail machine body 1; internal closure of

[0049] When the user uses the vending machine body 1, after paying fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com