Magnetic filter for high-precision machining field

A magnetic filter, high-precision technology, applied in the fields of magnetic separation, chemical instruments and methods, cleaning methods and utensils, etc., can solve the difference of iron removal effect of filtration and discharge, the pollution of fluid medium circulation loop, and affect the effect of high-precision processing. and other problems to achieve the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

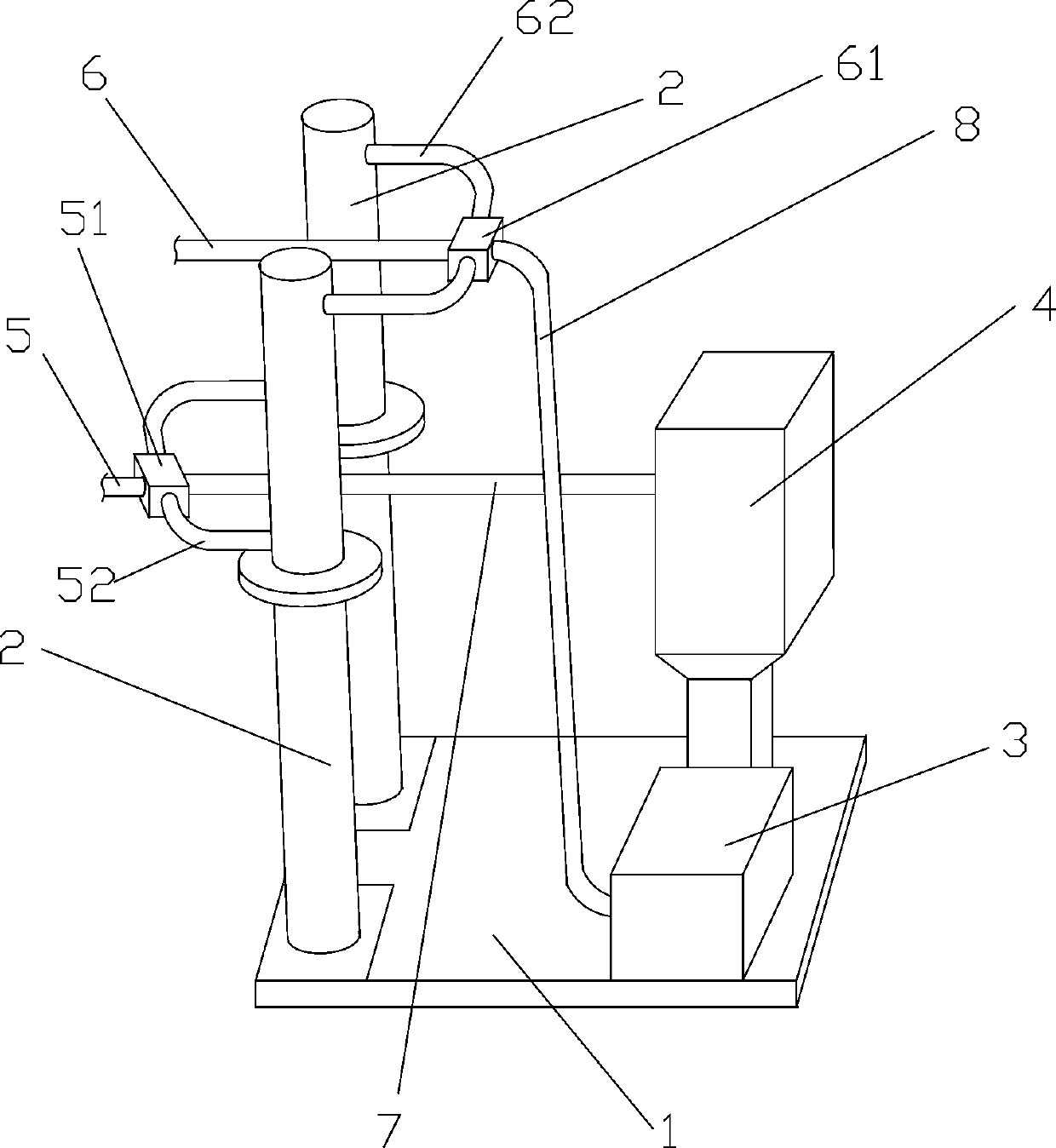

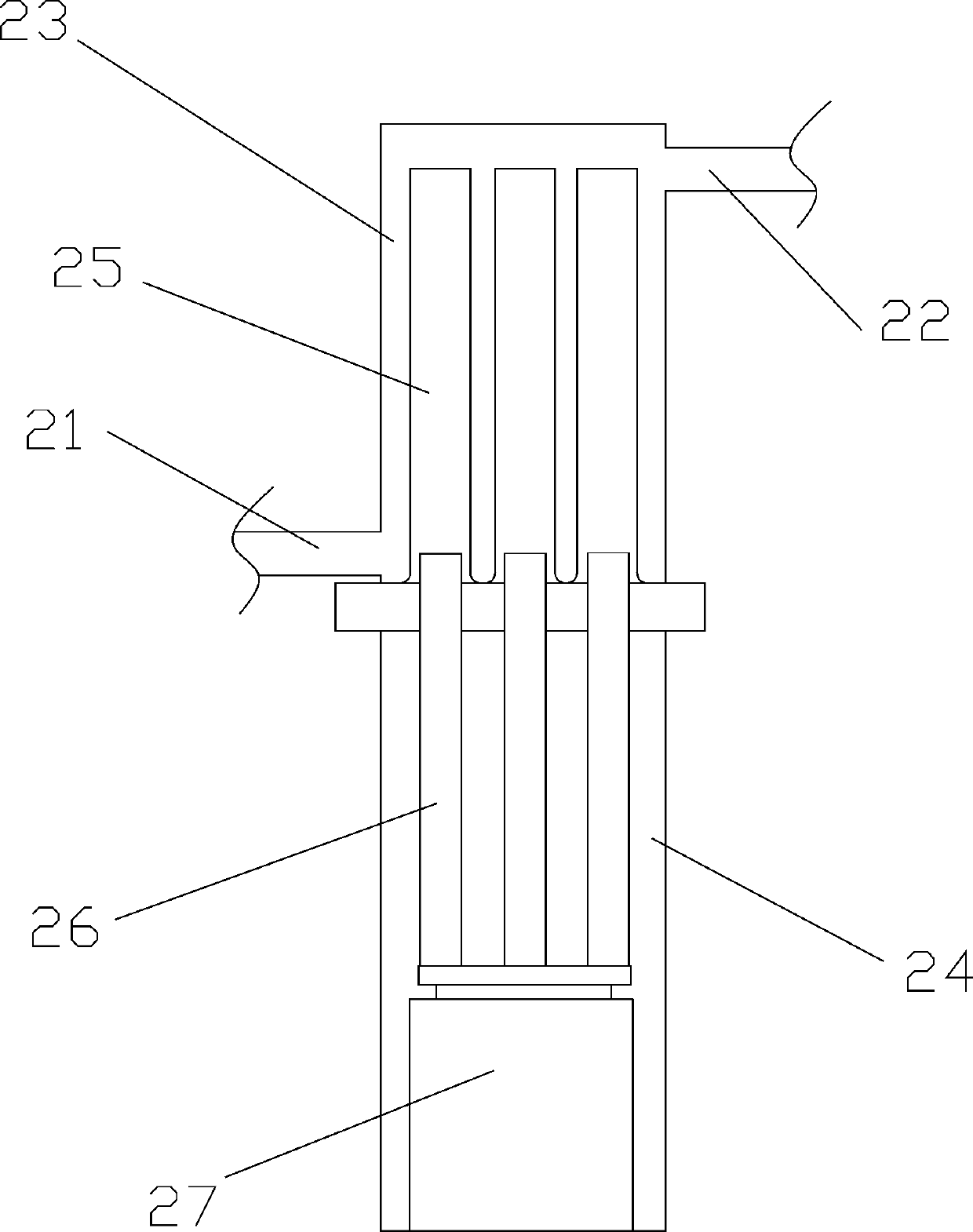

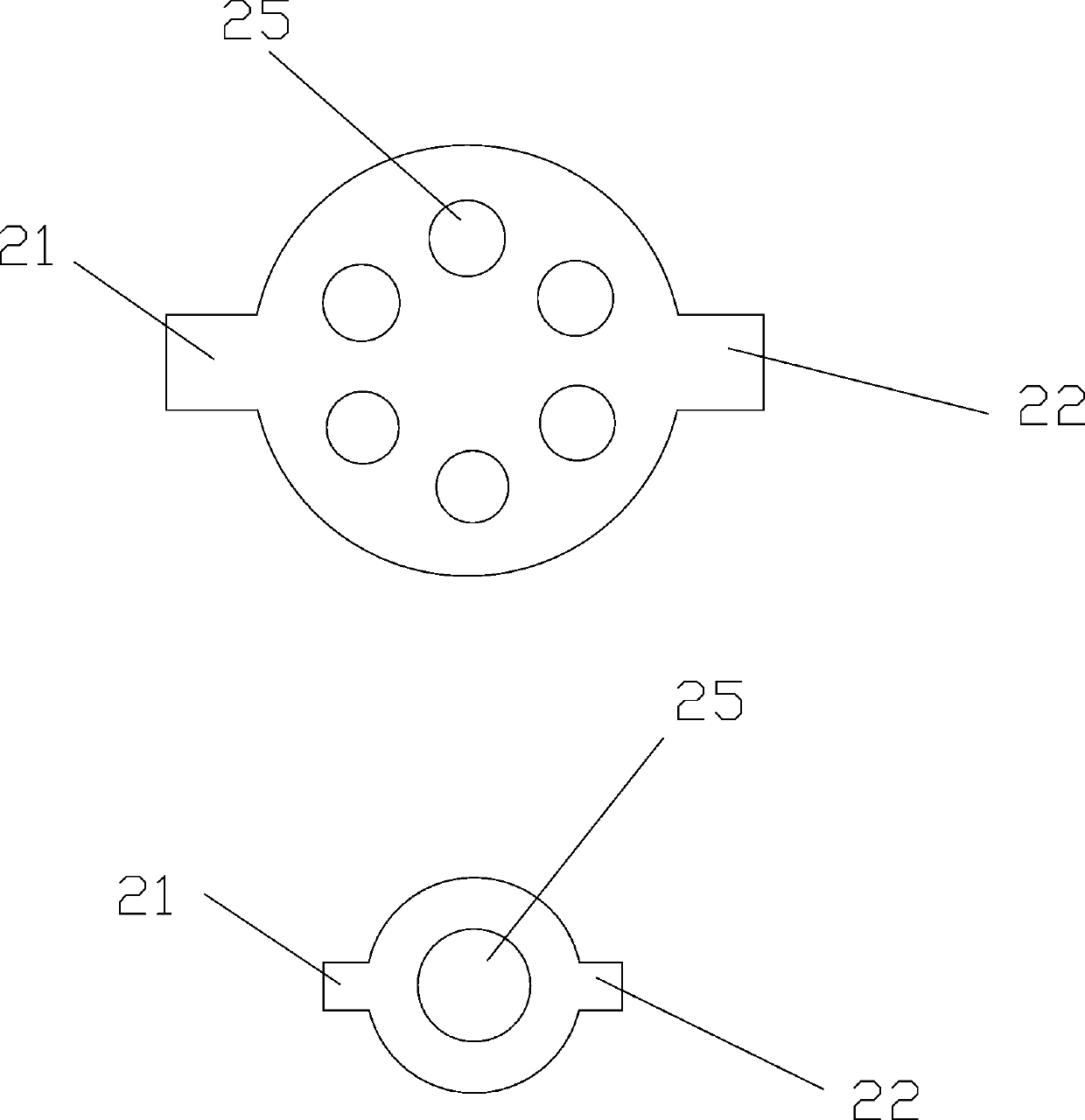

[0021] Embodiment 1: as Figure 1 to Figure 4 As shown, a magnetic filter for high-precision machining field includes a base plate 1, a filter tank 2, a cleaner 3 and a liquid storage tank 4 arranged on the base plate 1, wherein the number of filter tanks 2 is at least two. The filter tank 2 is connected with a liquid inlet pipe 5 and a liquid outlet pipe 6, and the liquid inlet pipe 5 and the liquid outlet pipe 6 are respectively provided with a liquid inlet divergent device 51 and a liquid outlet divergent device 61. The above-mentioned outlet manifold 61 is provided with a control valve. The filter tank 2 includes a liquid inlet 21 and a liquid outlet 22 arranged above the liquid inlet 21 . It also includes a cleaning device 3 , the cleaning device 3 includes a processing chamber 31 , and the processing chamber 31 is provided with a cleaning liquid inlet 32 , a cleaning liquid outlet 34 and a slag discharge port 33 . The liquid inlet manifold 51 is connected to the liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com