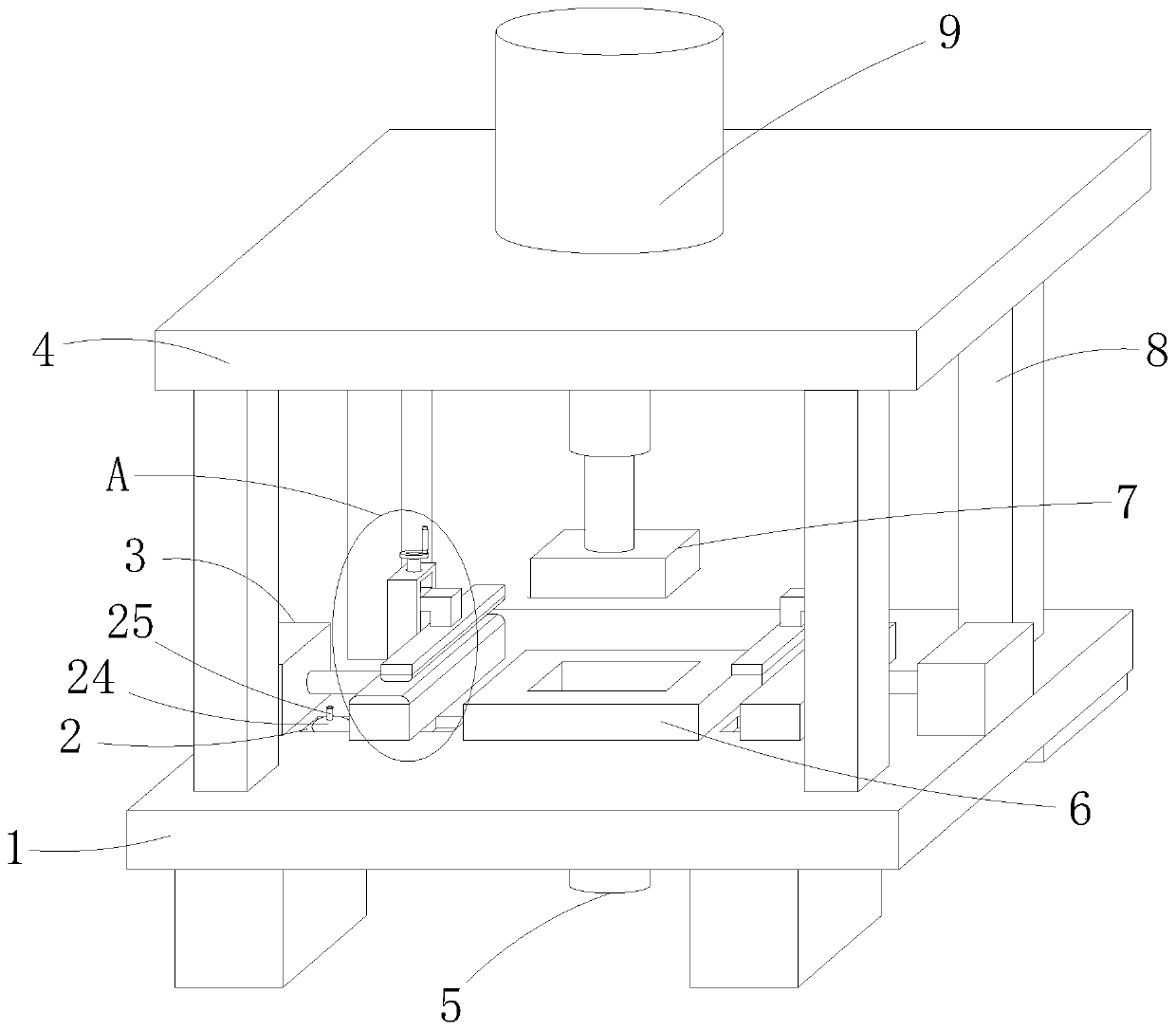

Metal plate stamping die

A stamping die and sheet metal technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems that the edges of sheet metal parts are prone to bending, metal shavings cannot be cleaned in time, and affect the precision of sheet metal stamping, etc., to achieve Effects of improving fixing strength, preventing displacement and swing, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

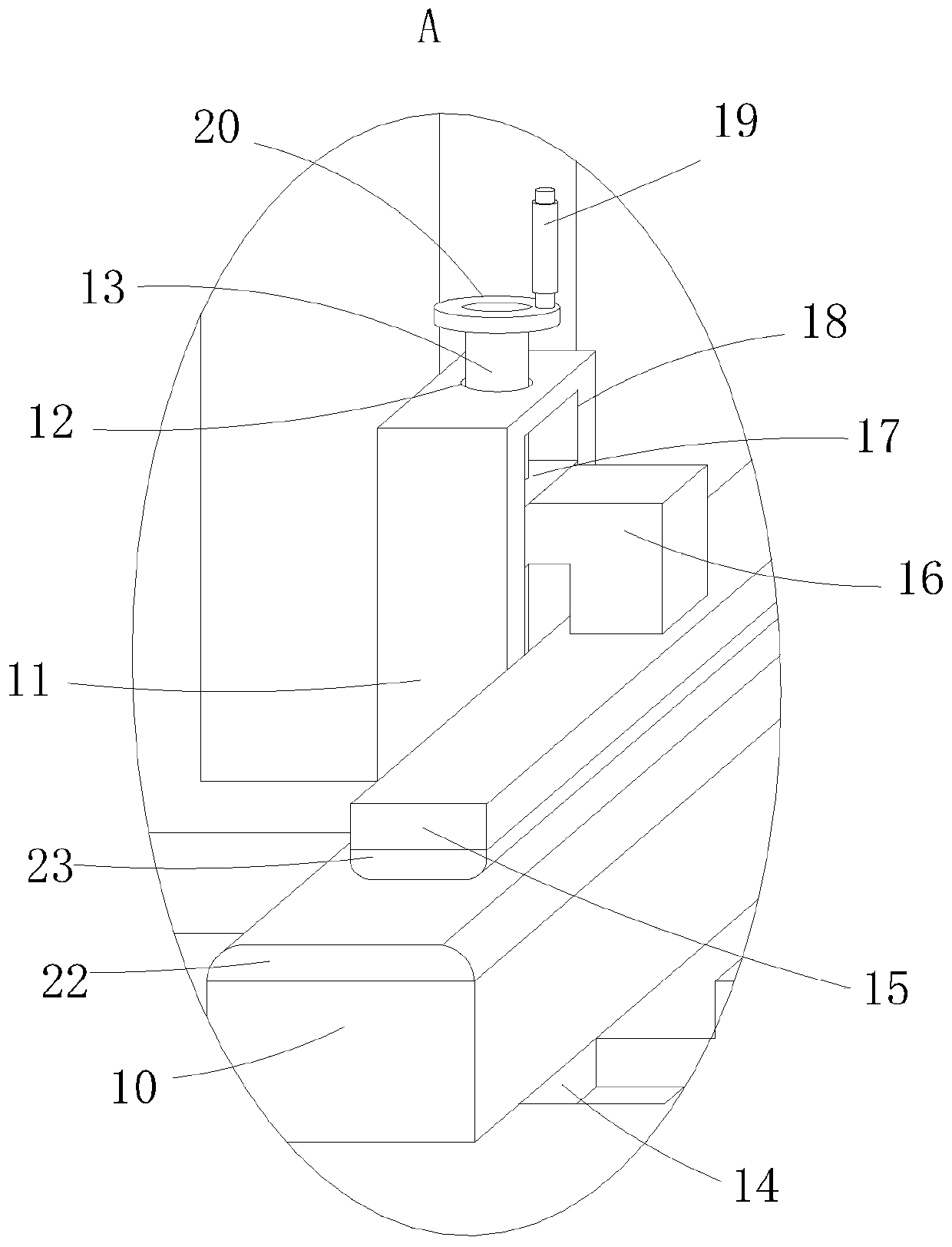

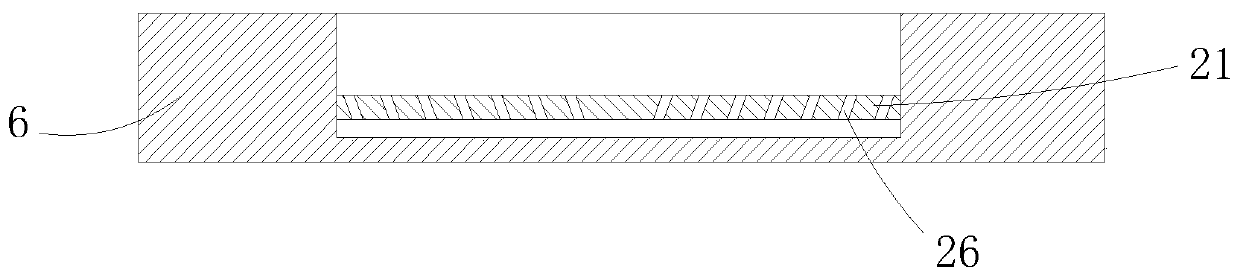

[0023] As an embodiment of the present invention, a hydraulic cylinder 2 5 is installed on the lower surface of the lower template 1, the hydraulic cylinder 2 5 is electrically connected to the controller, and the output end of the hydraulic cylinder 2 5 runs through the lower surface of the lower template 1 and the The lower surface of the die 6 extends into the cavity of the die 6 and is fixedly connected with a discharge plate 21; during work, after the sheet metal stamping is completed, the controller controls the hydraulic cylinder 25 to stretch out to make the discharge plate 21 and the concave The die 6 slides out, so that the metal scraps falling in the die 6 during the stamping process of the sheet metal parts are cleaned out of the die 6, preventing the excessive accumulation of metal scraps in the die 6 and affecting the stamping of the sheet metal parts, and the metal scraps Cleaning is convenient and quick, saving manpower and material resources.

[0024] As an em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com