Preparation method of paper product, paper product and aerosol generating device

A technology for producing devices and paper products, applied in the field of paper product manufacturing, can solve the problems of insufficient mechanical properties of paper products, environmental damage, easy breakage or tearing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

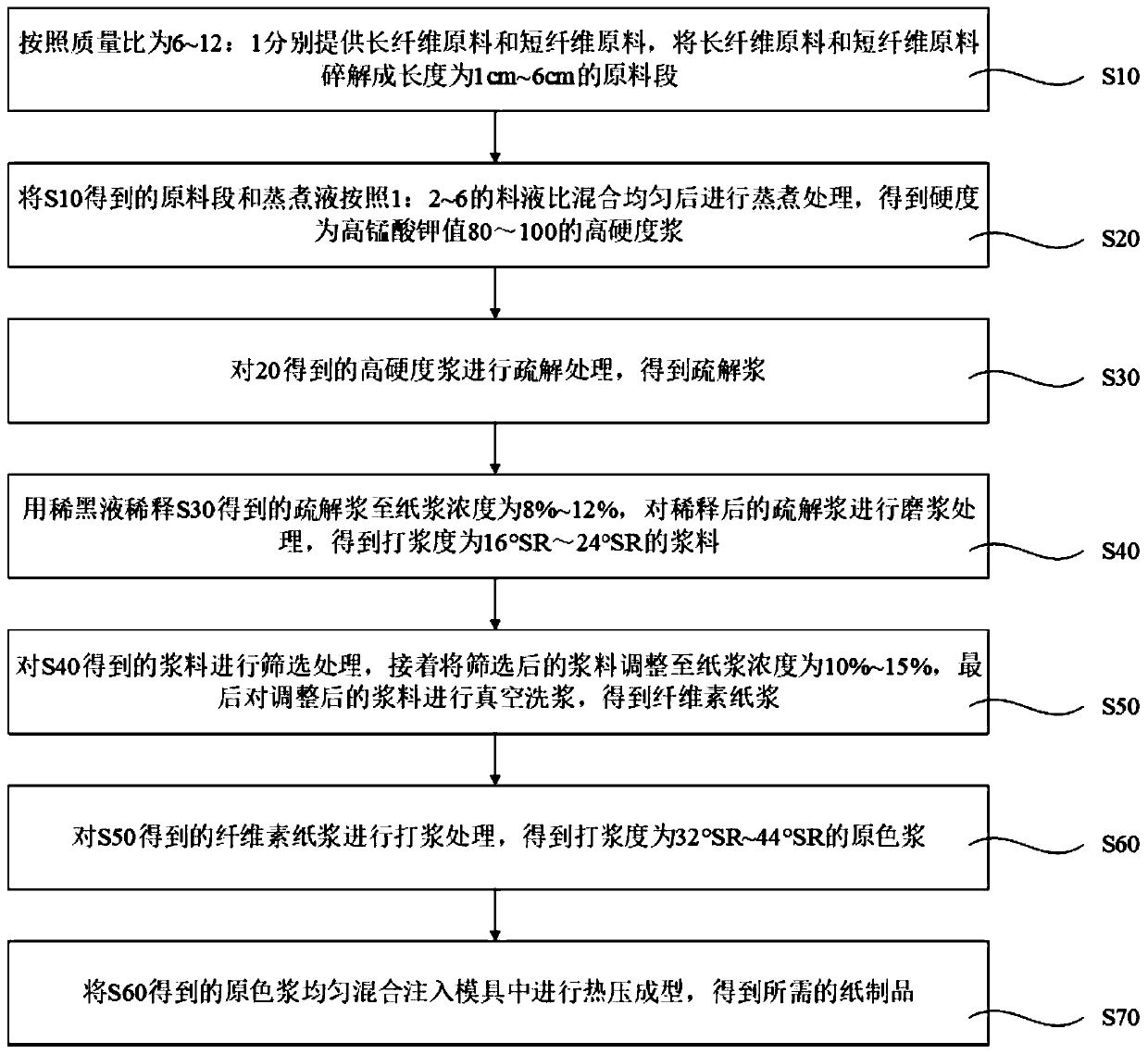

[0023] Such as figure 1 The preparation method of the paper product of one embodiment shown, comprises the steps:

[0024] S10. Provide long-fiber raw materials and short-fiber raw materials respectively according to a mass ratio of 6-12:1, and disintegrate the long-fiber raw materials and short-fiber raw materials into raw material segments with a length of 1 cm to 6 cm.

[0025] Long fibers can increase the strength of the produced paper products in the longitudinal direction. Controlling the addition of short fibers will not cause the produced paper products to be easily broken or torn, but also because long fibers and short fibers are interwoven to form a weave-like structure , so that the addition of a small amount of short fibers improves the folding resistance and fracture of the prepared paper products.

[0026] Generally speaking, the long-fiber raw material is bamboo, and the short-fiber raw material is bagasse.

[0027] Preferably, the bamboo has a bamboo age of 3...

Embodiment 1

[0068] Select water bamboo and white bamboo with a bamboo age of 3 years, provide raw materials according to the mass ratio of water bamboo, white bamboo and bagasse as 6:3:1, and dry the raw materials into raw materials with a length of 5cm part.

[0069] Mix the raw material section and the cooking liquid evenly at a material-to-liquid ratio of 1:4, and then use a continuous digester to feed steam to heat up to 135°C, heat up, deflate, and keep warm for 80 minutes to obtain a hardness with a potassium permanganate value of 90. Hard pulp, wherein the cooking liquid is KOH with a mass concentration of 17%.

[0070] The high-hardness pulp is sent to a high-consistency refiner for deflaking to obtain deflapped pulp, and the deflaking time is 30 minutes to 40 minutes.

[0071] Dilute the decomposed bamboo pulp with dilute black liquor to a concentration of 10%, and refine the diluted pulp to obtain a pulp with a beating degree of 20°SR.

[0072] The pulp after refining is scree...

Embodiment 2

[0078] Select water bamboo with a bamboo age of 3 years, provide raw materials according to the mass ratio of water bamboo and bagasse at 9:1, and use the raw material dry method to disintegrate the raw material into raw material segments with a length of 5 cm.

[0079] Mix the raw material section and the cooking liquid evenly at a material-to-liquid ratio of 1:4, and then use a continuous digester to feed steam to heat up to 135°C, heat up, deflate, and keep warm for 80 minutes to obtain a hardness with a potassium permanganate value of 90. Hard pulp, wherein the cooking liquid is KOH with a mass concentration of 17%.

[0080] The high-hardness pulp is sent to a high-consistency refiner for deflaking to obtain deflapped pulp, and the deflaking time is 30 minutes to 40 minutes.

[0081] Dilute the decomposed bamboo pulp with dilute black liquor to a concentration of 10%, and refine the diluted pulp to obtain a pulp with a beating degree of 20°SR.

[0082] The pulp after refi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Tear | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com