Mass concrete cooling device and using method

A technology of mass concrete and cooling device, applied in infrastructure engineering, architecture, building construction, etc., can solve problems such as loss of life and property, cracking of concrete, affecting the safe use of structures, etc., to improve cooling efficiency and ensure heat absorption. Ability, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] specific implementation plan

[0034] In order to make the purpose, technical solution and feasibility of the present invention more clear and detailed, the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific examples described below are only used to explain the present invention, not to limit the present invention.

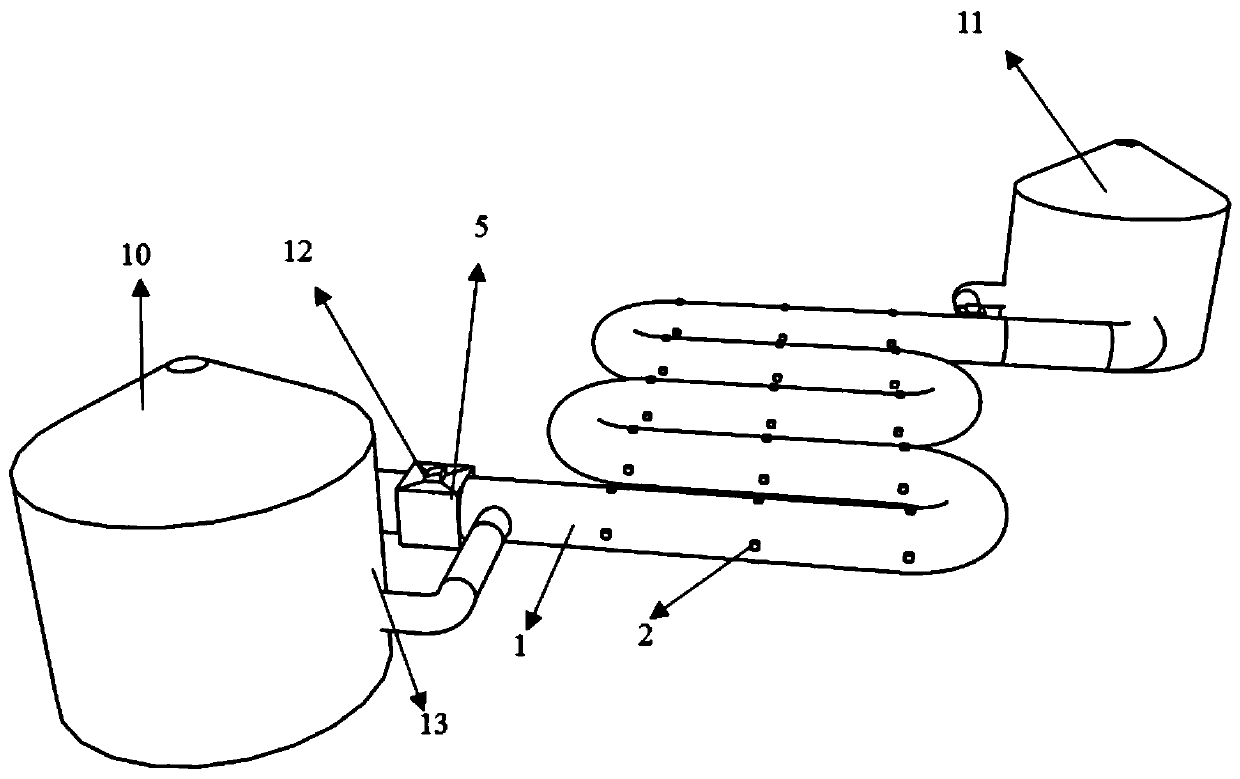

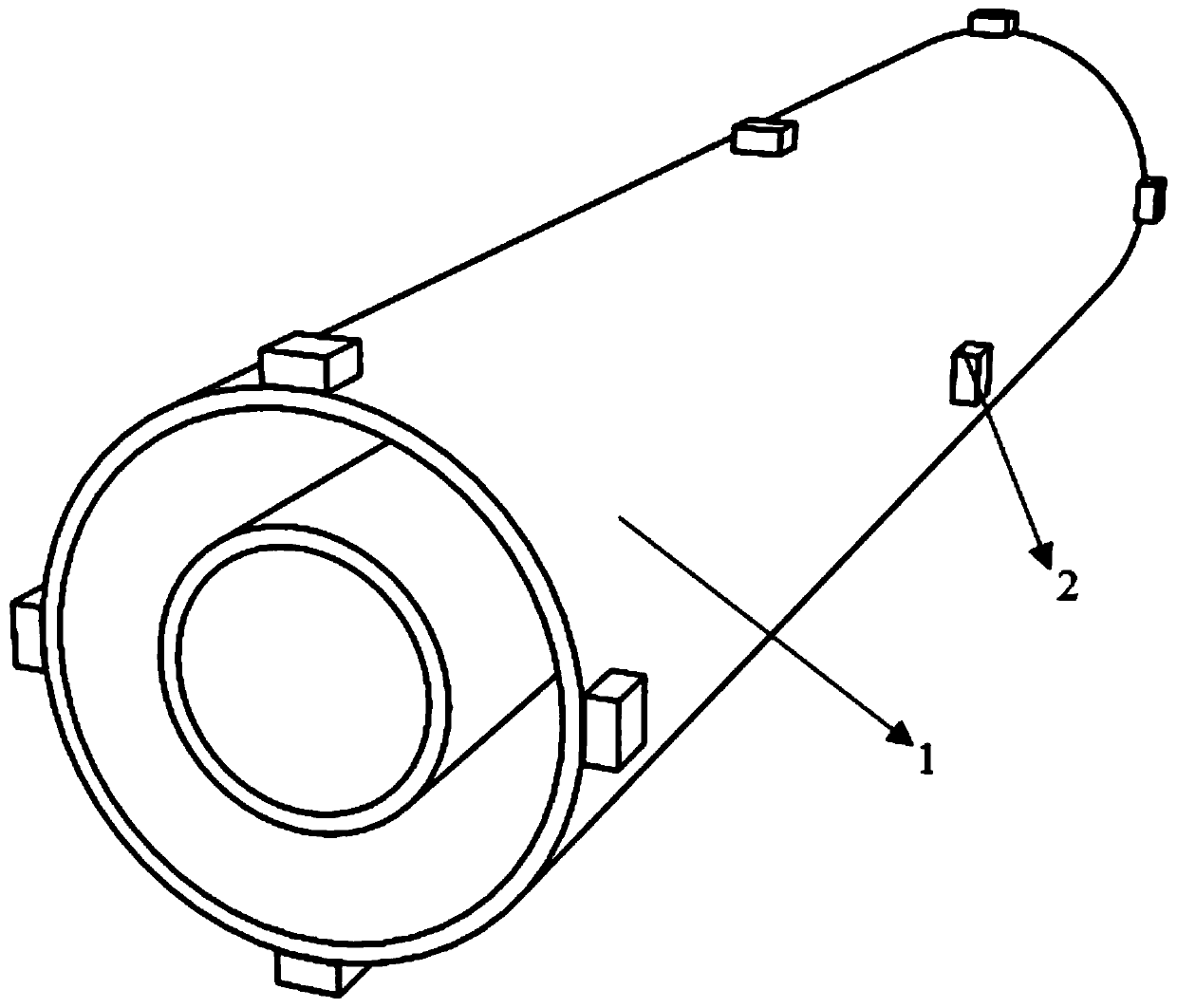

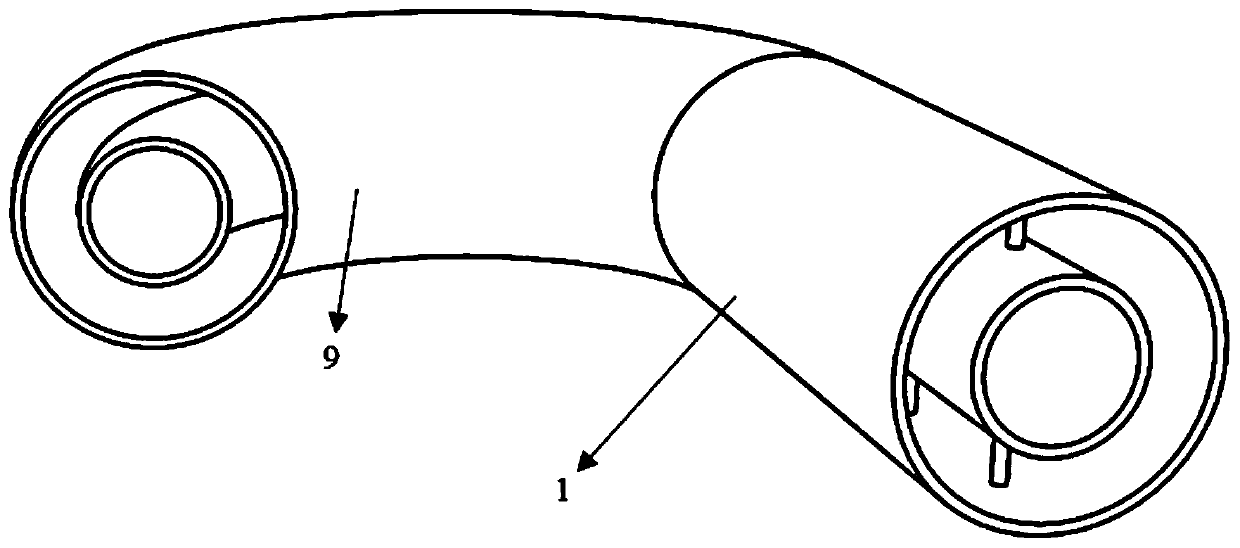

[0035] see Figure 1 to Figure 7 , a large-volume concrete cooling device, including a multi-layer cooling system arranged in the vertical direction, a No. 1 coolant storage tank 10, and a No. 2 coolant storage tank 11. The cooling system includes a pipeline system and a cooling liquid regulation system. . A data monitoring and control system, the pipeline system includes a double-layer combined pipe 1 and a double-layer rubber hose joint 9; the double-layer combined pipe 1 includes an end segment and an intermediate segment; the intermediate segment i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com