Heat sink and preparation technology thereof

A preparation process and a technology for a heat sink, applied in the field of a heat sink and its preparation process, can solve the problems of low thermal conductivity, poor thermal conductivity, low heat storage and release rate, etc., and achieve improved thermal conductivity, low manufacturing cost, and improved service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

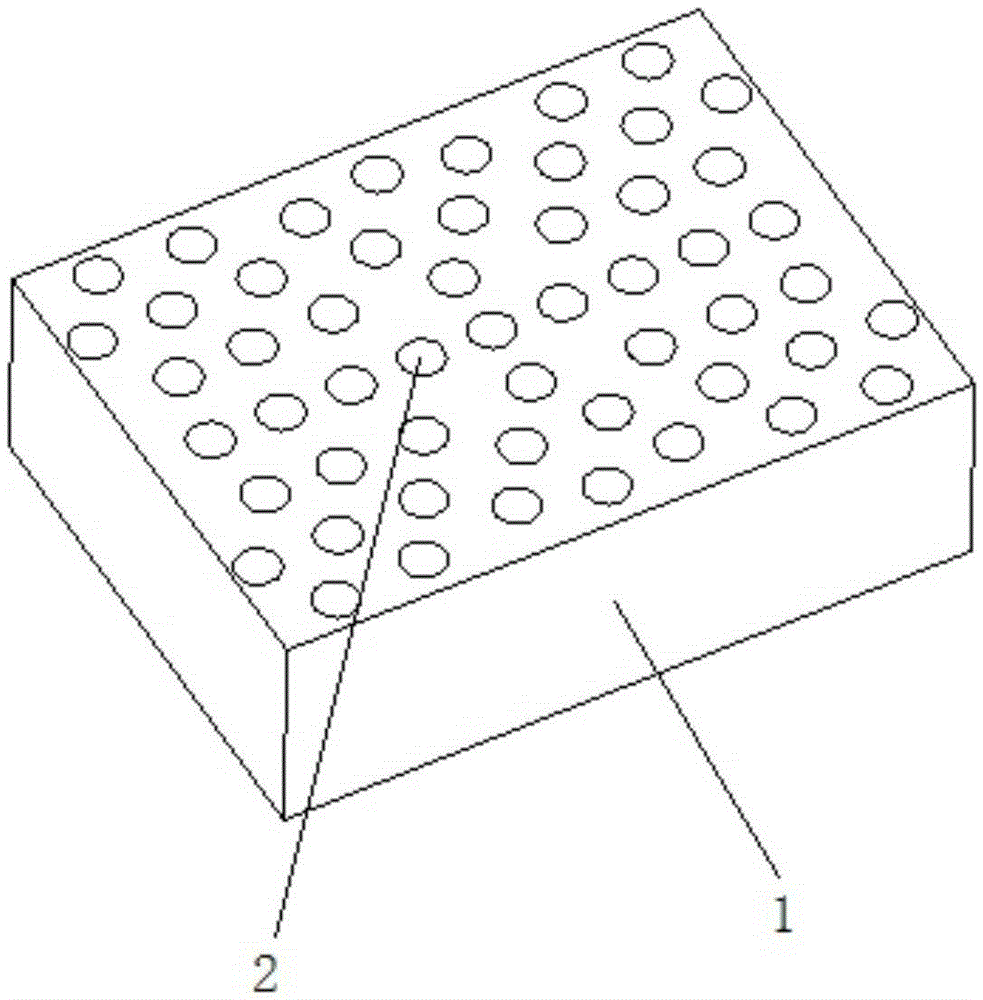

[0029] See figure 1 with figure 2 , the present invention includes a body 1; the body 1 is provided with a plurality of through holes 2 for placing heating elements; the body 1 includes a substrate with thermal conductivity; the substrate has open pores; the substrate has The open pores are filled with phase change materials.

[0030] The through holes 2 on the body 1 are arranged in a rectangular array.

[0031] The distance between the adjacent through holes is 3mm.

[0032] The material of the matrix is foamed graphite, and the diameter of the open pores is 0.01 μm; the open porosity of the matrix is 30%.

[0033] The phase change material is solid-liquid phase change material paraffin.

[0034] The preparation technology of radiator seat among the present invention, comprises the following steps:

[0035] A. Put the matrix with the through holes 2 into the pressure vessel and fill the open pores of the matrix with the phase change material through the pressure in...

Embodiment 2

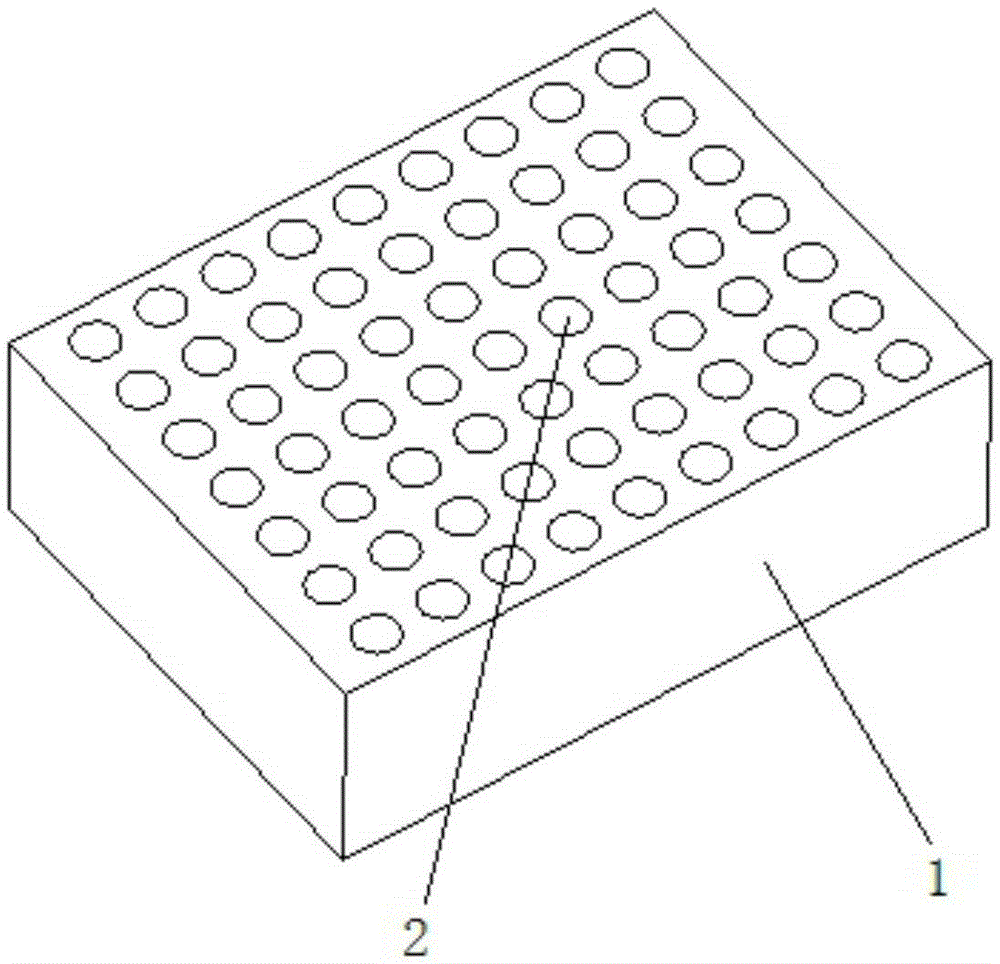

[0039] See figure 1 with image 3 In the present invention, the main body 1 is provided with multiple rows of through-hole groups arranged in parallel; the through-hole groups have a plurality of equidistant and linearly arranged through-holes 2; the through-holes 2 of the adjacent through-hole groups are staggered from each other; The distance between the adjacent through holes is 5 mm. Other technical features are the same as those in Embodiment 1. Its preparation method is identical with embodiment one.

Embodiment 3

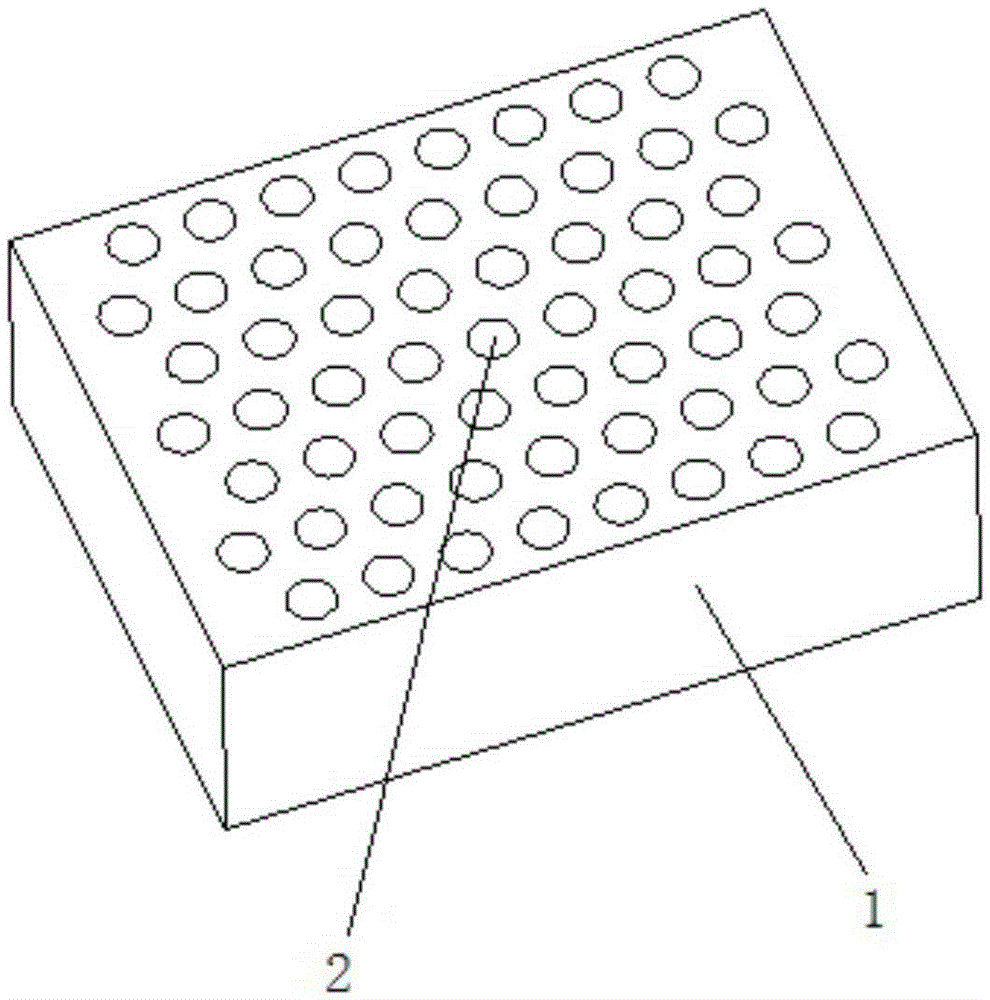

[0041] See figure 1 with Figure 4 In the present invention, the main body 1 is provided with multiple rows of through-hole groups arranged in parallel; the through-hole groups have a plurality of linearly equidistantly arranged through-holes 2 and the adjacent through-holes 2 partially overlap; the adjacent through-hole groups The through holes 2 are staggered from each other. Other technical features are the same as those in Embodiment 1. Its preparation method is identical with embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com