Embedded installation method for heating furnace top energy-saving thermal radiation body

A heat radiation body and installation method technology, which is applied to lighting and heating equipment, furnaces, integral linings, etc., can solve problems affecting the installation of heat radiation bodies, the promotion of energy-saving technology of heat radiation bodies, and the life of furnace tops, etc., to improve Energy-saving effect, simple and easy method, and the effect of reducing the amount of repairs and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

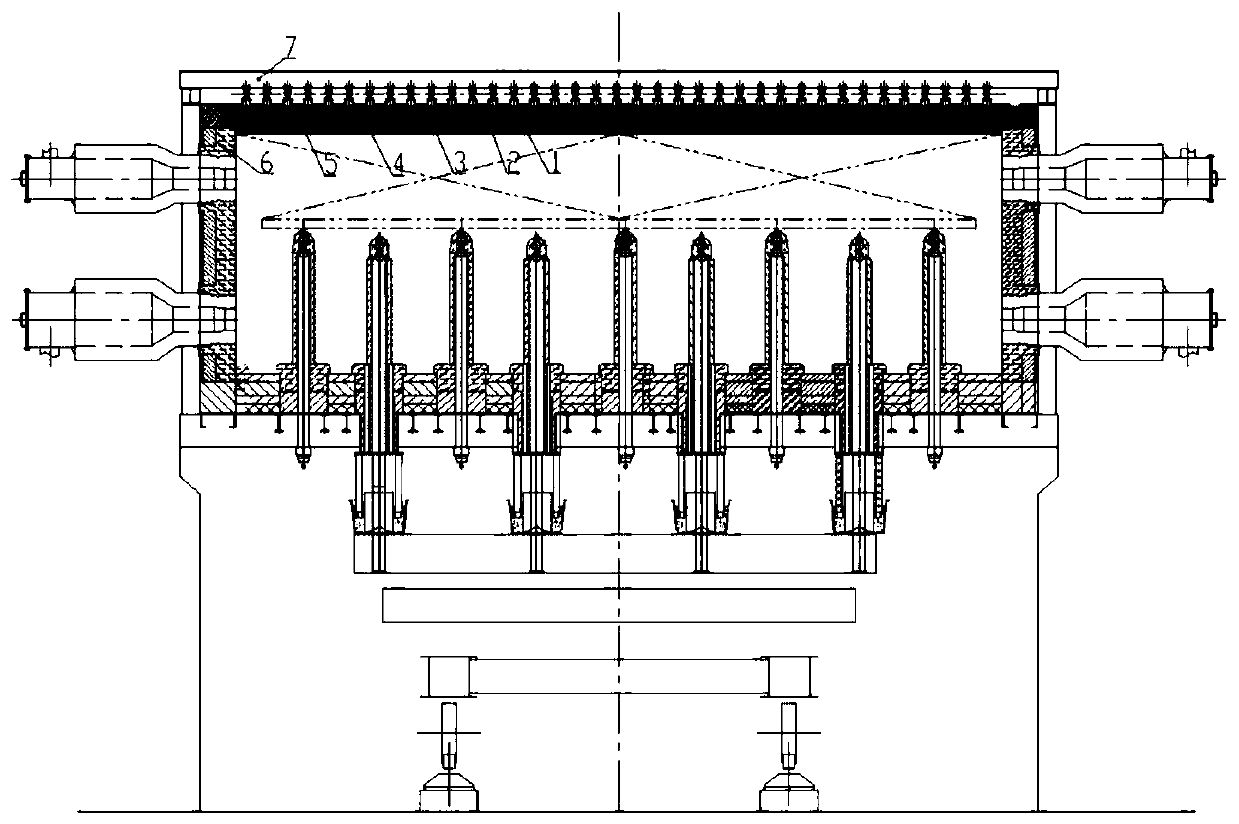

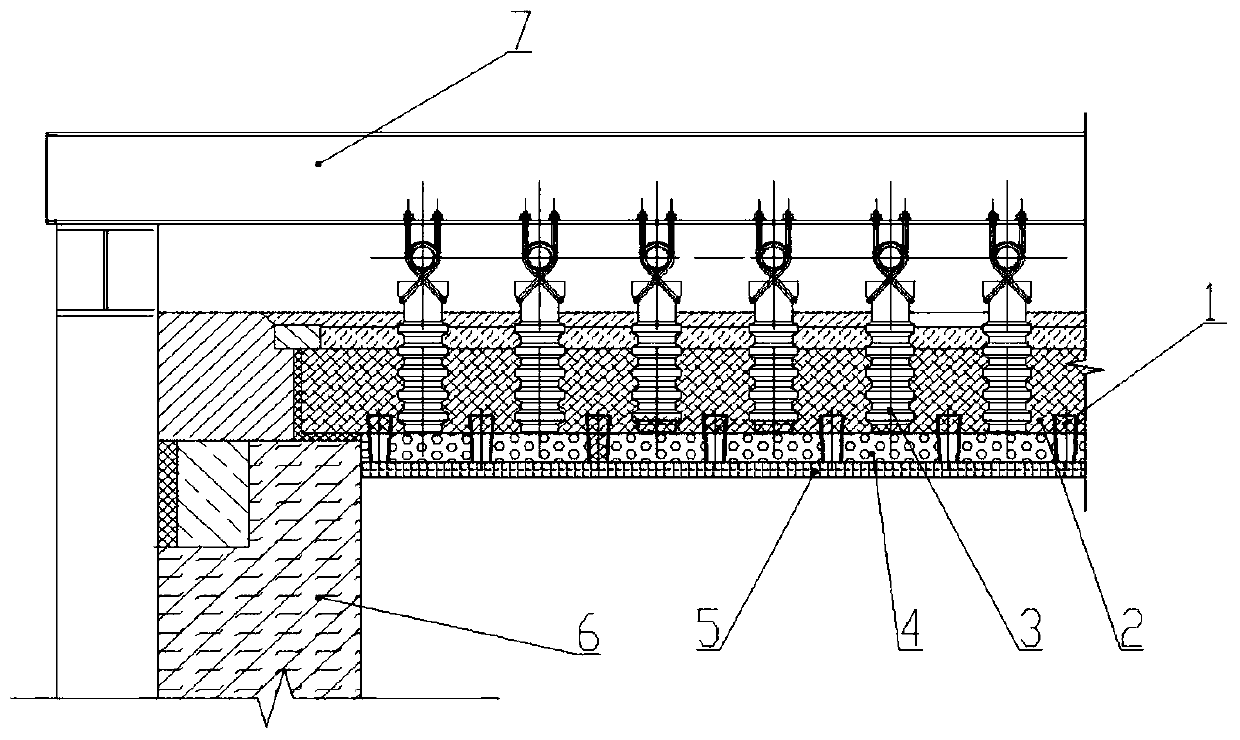

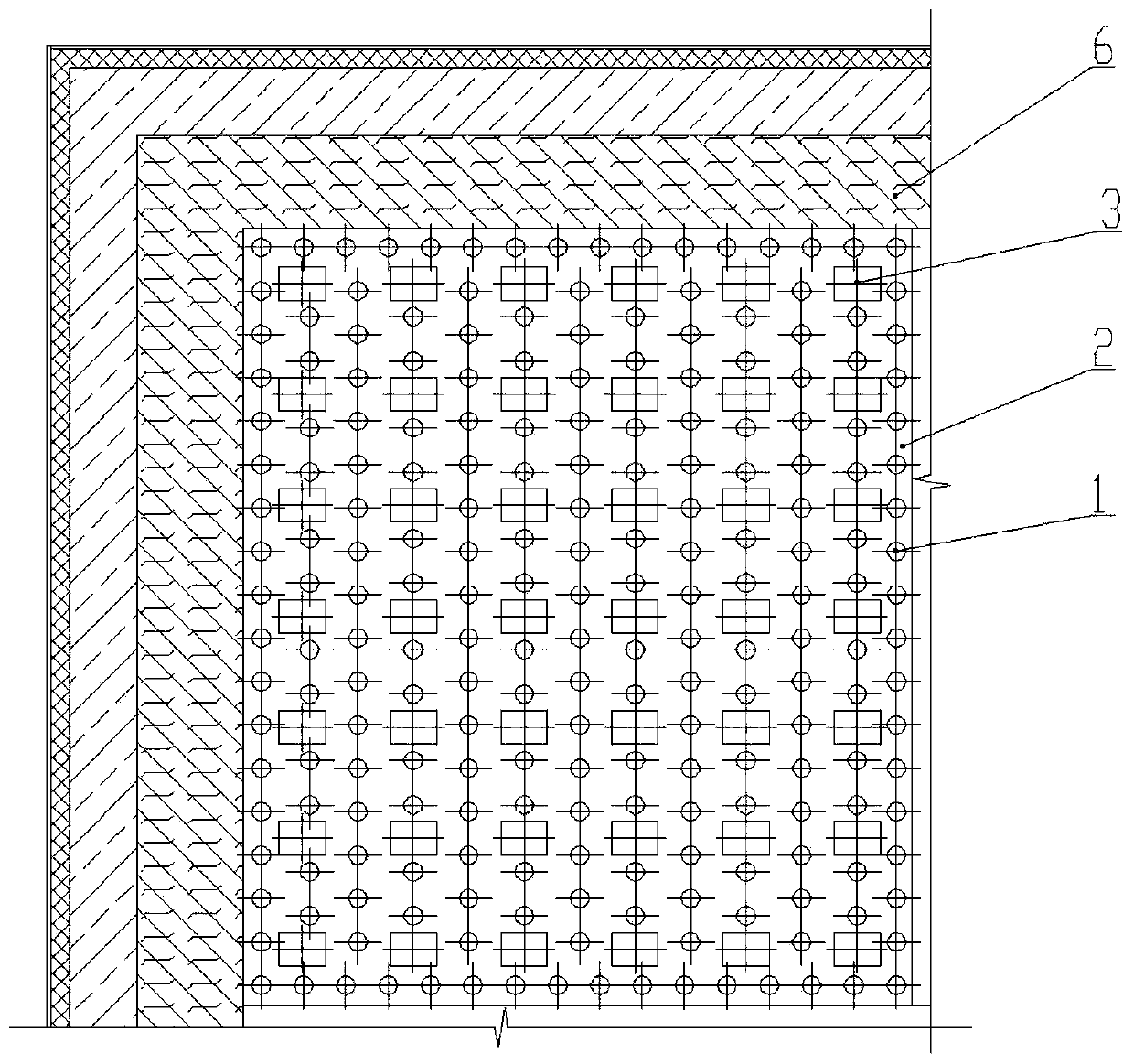

[0032] Refer to attached Figure 1-4 , an embedded installation method for an energy-saving heat radiator on the roof of a heating furnace, one end of the heat radiator 1 is an installation end, and the other end is a radiation end, comprising the following steps:

[0033] ① Embed the installation end of the heat radiator 1 into the refractory material of the furnace top according to the designed quantity and position;

[0034] ② Lay pouring formwork 5 on the furnace roof;

[0035] ③ Lay a certain thickness of filler 4 on the pouring template 5, and make the radiation end of the heat radiator 1 be located in the filler 4;

[0036] ④ According to the construction requirements, use castable 2 to pour the furnace roof, so that the installation end of the heat radiator 1 and the furnace roof are poured into one;

[0037] ⑤ After the furnace top pouring is comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com