Improved water chilling unit testing device with heat recovery function

A chiller and testing device technology, applied in measuring devices, testing of machines/structural components, instruments, etc., to achieve the effects of reducing operating flow and overall energy consumption, simplifying cooling schemes, and large heat transfer temperature differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

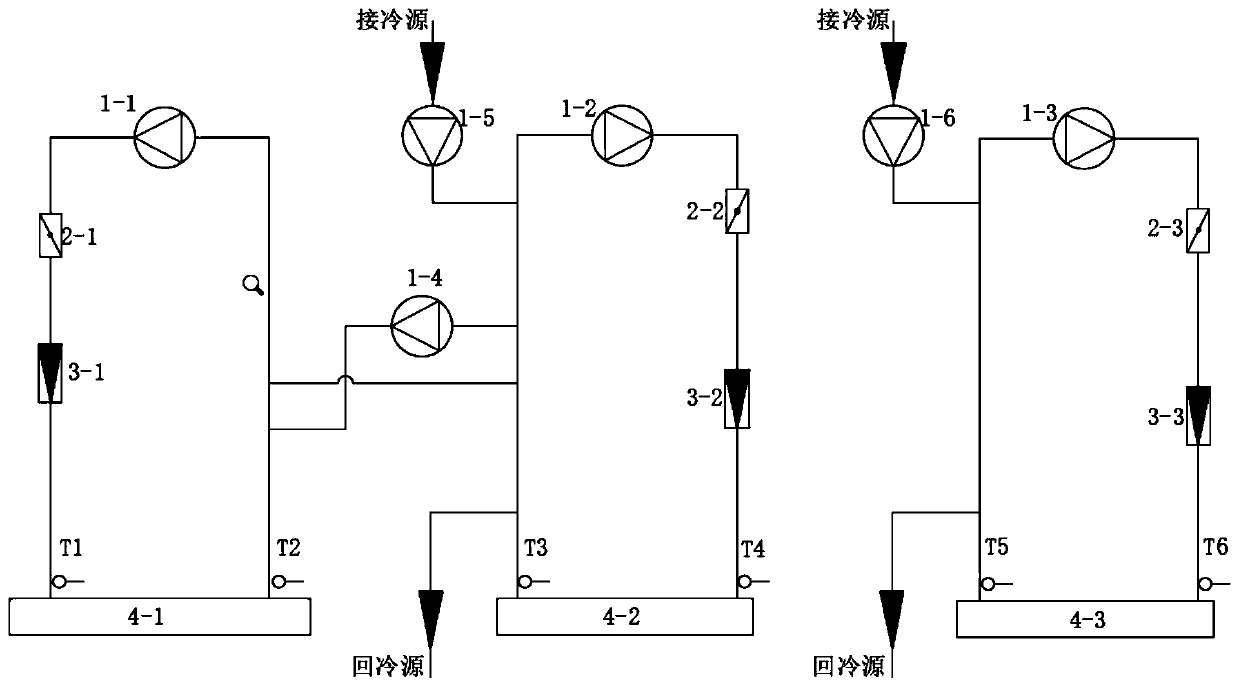

[0035] Such as figure 1 As shown, an improved test device for testing chillers with heat recovery function, including the evaporator side circulation pipeline connected to the evaporator 4-1, and the condenser side circulation pipeline connected to the condenser 4-2 . The heat recovery unit side circulation pipeline connected to the heat recovery unit 4-3, the first water conversion circulation pipeline, the second water conversion circulation pipeline, and the third water conversion circulation pipeline. The evaporator 4-1 and the circulation pipeline on the evaporator side, the condenser 4-2 and the circulation pipeline on the condenser side, the circulation pipeline on the heat recovery unit and the heat recovery unit 4-3 all form a closed cycle. The circulation pipeline on the evaporator side communicates with the circulation pipeline on the condenser side through the first water exchange circulation pipeline, the heat recovery side circulation pipeline communicates with t...

Embodiment 2

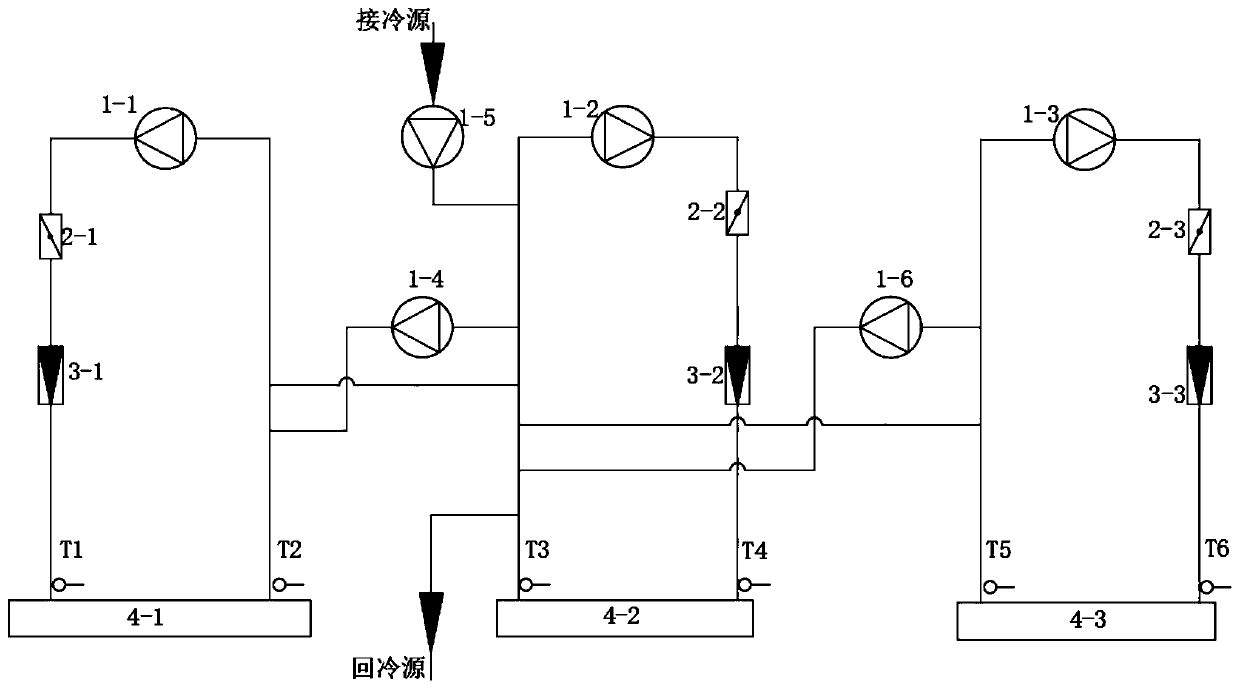

[0046] Such as figure 2 As shown, an improved test device for testing chillers with heat recovery function, including the evaporator side circulation pipeline connected to the evaporator 4-1, and the condenser side circulation pipeline connected to the condenser 4-2 . The heat recovery unit side circulation pipeline connected to the heat recovery unit 4-3, the first water conversion circulation pipeline, the second water conversion circulation pipeline, and the third water conversion circulation pipeline. The evaporator 4-1 and the circulation pipeline on the evaporator side, the condenser 4-2 and the circulation pipeline on the condenser side, the circulation pipeline on the heat recovery unit and the heat recovery unit 4-3 all form a closed cycle. The circulation pipeline on the evaporator side is communicated with the circulation pipeline on the condenser side through the first water exchange pipeline, and the circulation pipeline on the heat recovery side is communicated ...

Embodiment 3

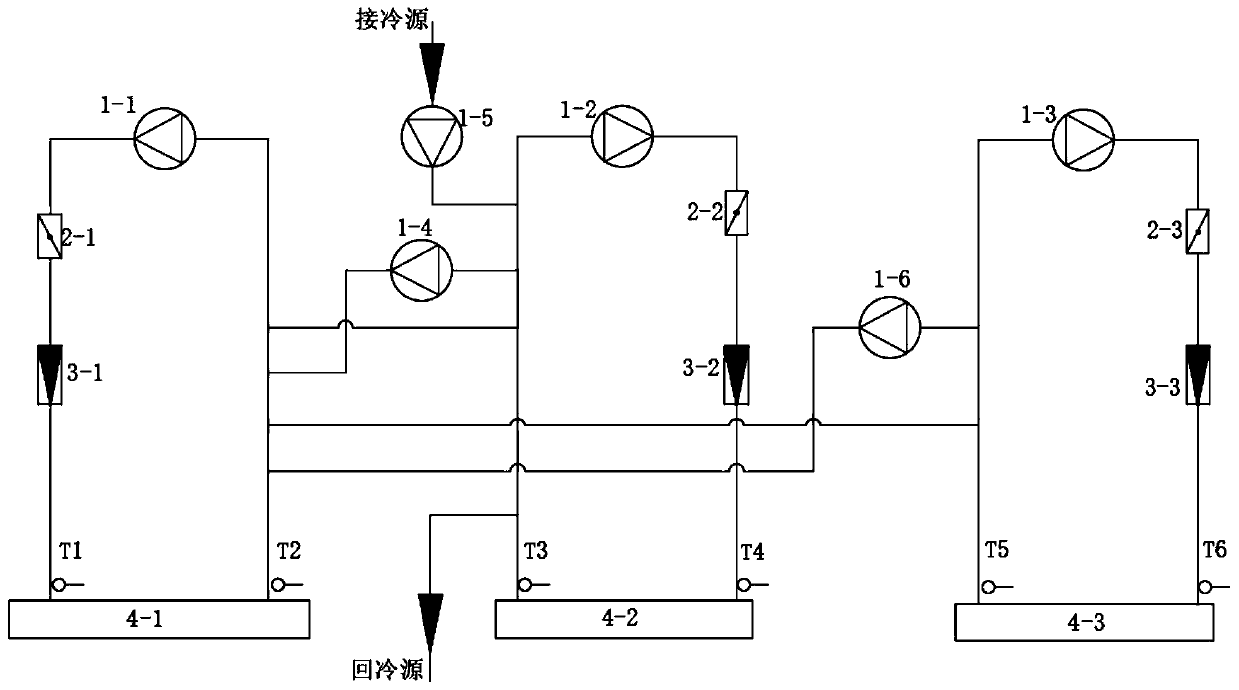

[0056] Such as image 3 As shown, an improved test device for testing chillers with heat recovery function, including the evaporator side circulation pipeline connected to the evaporator 4-1, and the condenser side circulation pipeline connected to the condenser 4-2 . The heat recovery unit side circulation pipeline connected to the heat recovery unit 4-3, the first water conversion circulation pipeline, the second water conversion circulation pipeline, and the third water conversion circulation pipeline. The evaporator 4-1 and the circulation pipeline on the evaporator side, the condenser 4-2 and the circulation pipeline on the condenser side, the circulation pipeline on the heat recovery unit and the heat recovery unit 4-3 all form a closed cycle. The circulation pipeline on the evaporator side is communicated with the circulation pipeline on the condenser side through the first water exchange pipeline, the circulation pipeline on the heat recovery side is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com