Fatigue life prediction method for composite laminate containing layered damage

A technology for fatigue life prediction and composite material layers, which is applied in computer material science, special data processing applications, instruments, etc., to achieve the effects of convenient engineering application, good consistency, and reduced test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

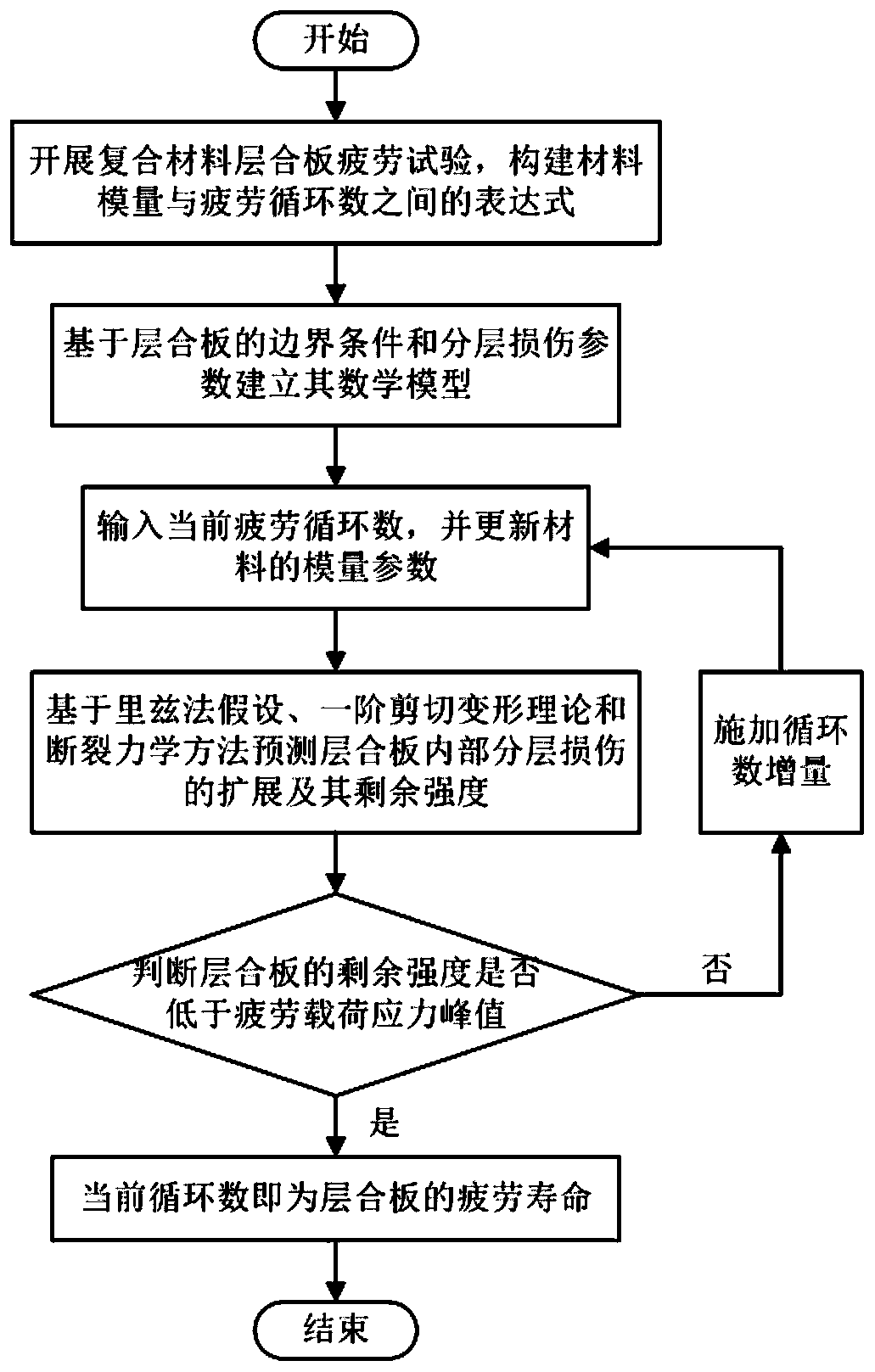

Method used

Image

Examples

Embodiment 1

[0043] Example 1: Fatigue Life Prediction of Composite Laminates with Circular Delamination Damage

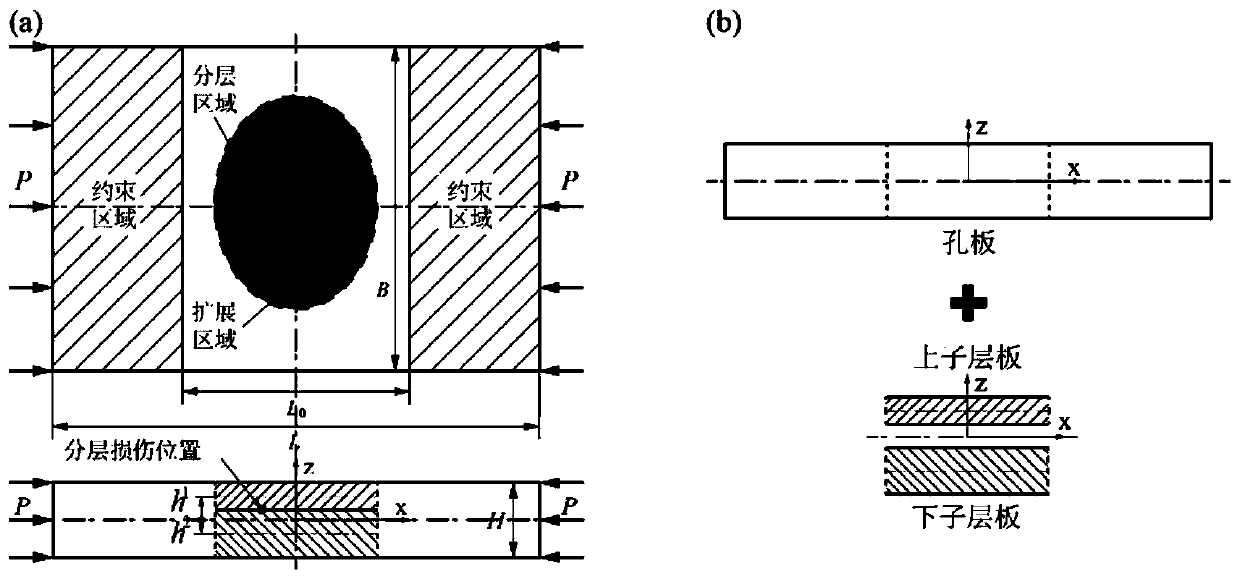

[0044] like figure 2 As shown, for a rectangular laminate with a geometric dimension of L (length) × B (width) × H (thickness), there is a circular layer with a radius of r in the center of a certain interlayer in the thickness direction. The laminate is subjected to fatigue compression loads in the x direction, while all degrees of freedom except the x direction are constrained to the constrained region.

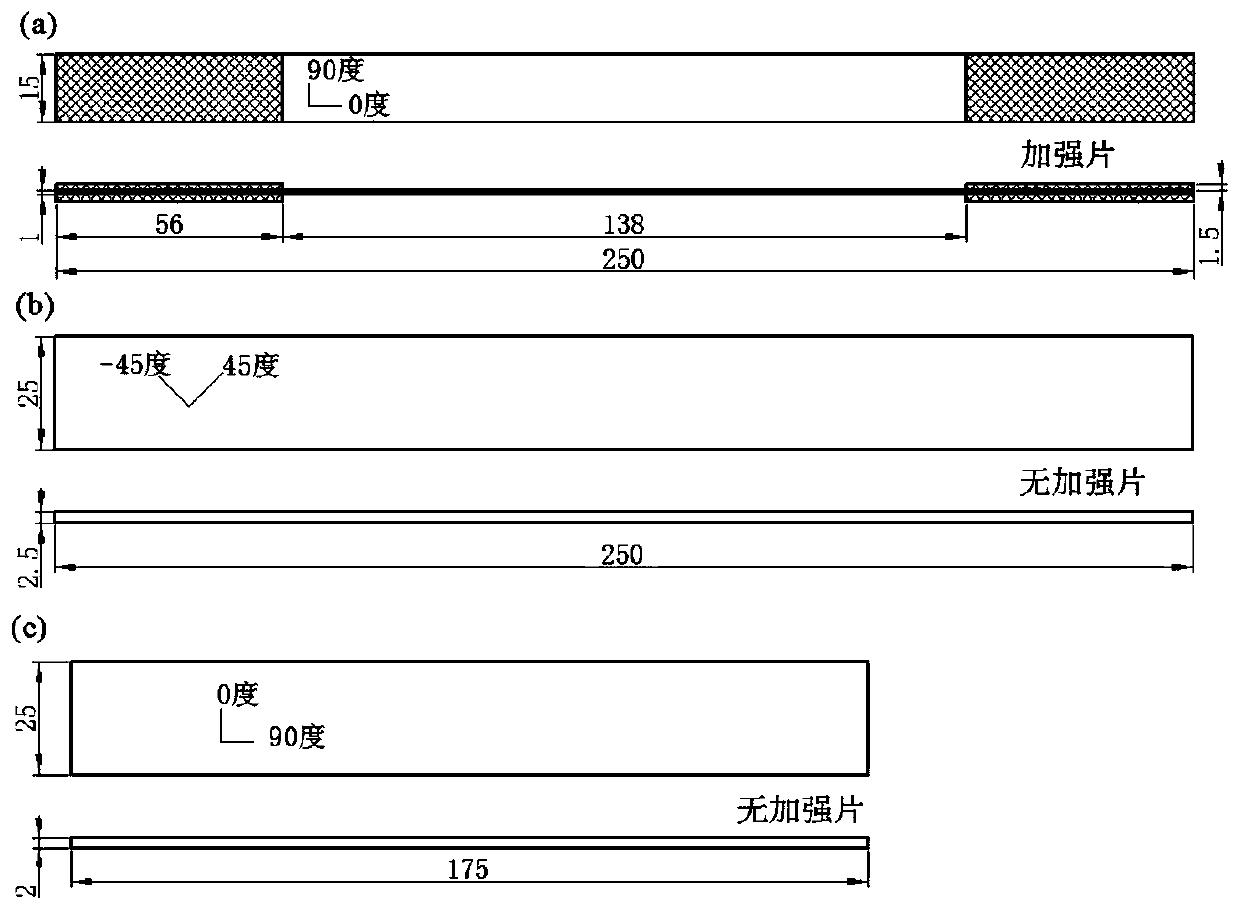

[0045] 1. According to the ASTM D3039 test standard, combined with the T300 / QY8911 composite material system, the basic performance tests of 0-degree tensile, ±45-degree vertical and horizontal shear and 90-degree tensile test specimens are as follows: image 3 shown. Carry out fatigue tests under different stress ratios, and obtain the q-N curve and stiffness degradation curve of the test piece as Figure 4 shown. Will Figure 4 The median life of the three types of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com