Material demand prediction management method based on material whole-process data

A technology of demand forecasting and management methods, which is applied in the field of electric power material information processing, can solve problems such as blurring the main responsibility and affecting the refinement of material management, and achieve the effect of improving forward-looking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

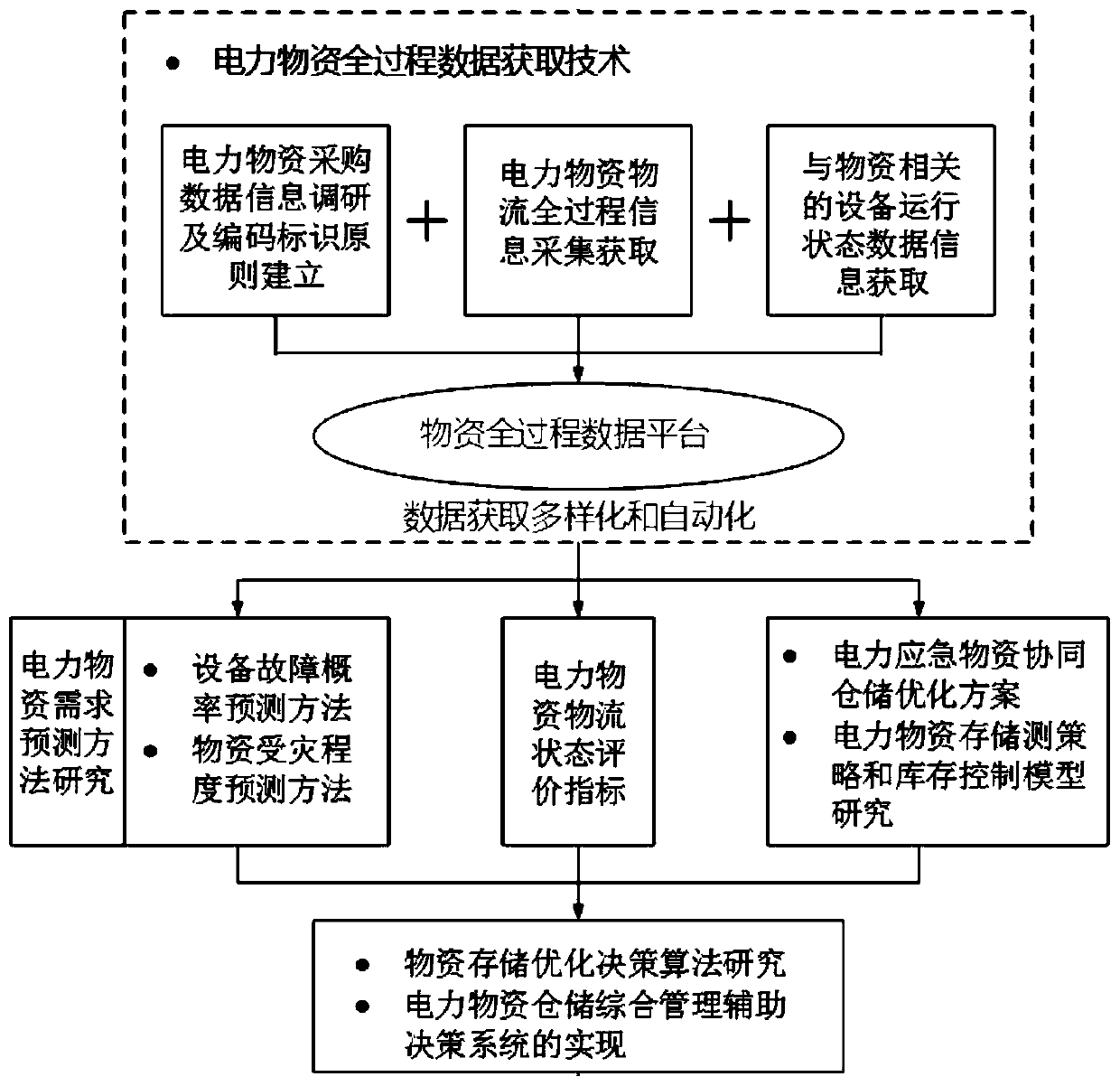

Embodiment 1

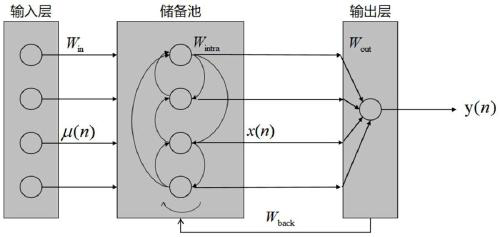

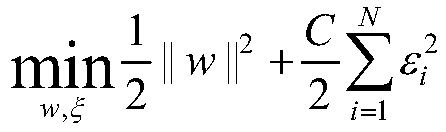

[0033] refer to Figure 1~2To illustrate, this embodiment provides a material demand forecasting management method based on the whole process data of materials, which can integrate material-related data scattered in different systems such as current materials and biotechnology to form material process data. For daily material reserves, Establish the timely supply of daily materials with guaranteed quality, and use big data analysis technology to predict the operating status and environment of different time, different locations, and different equipment for emergency materials, so as to guide the advance storage of emergency repair materials types, scales and locations. According to extreme weather According to the results of the deduction, a three-level major disaster storage model of emergency supplies + supplier emergency reserves + social force reserves will be constructed to improve the forward-looking material management of power grid companies and ensure reliable operatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com